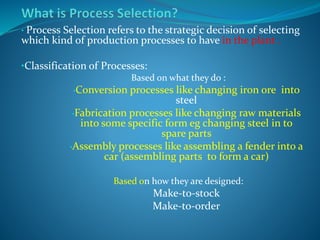

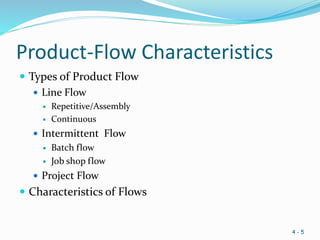

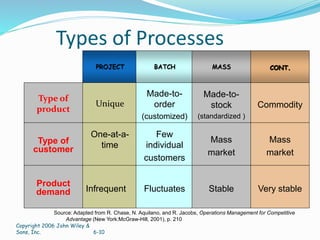

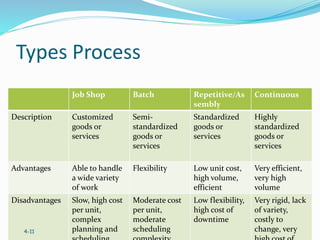

This document discusses different types of production processes and factors that influence process selection. It defines processes as groups of related tasks with inputs and outputs. Process types include job shop, batch, repetitive/assembly line, and continuous processes. Key factors that determine process choice are market conditions, capital/labor requirements, management skills, materials costs, and technology. The document also outlines different product flow characteristics like line, intermittent, batch, and project flows.