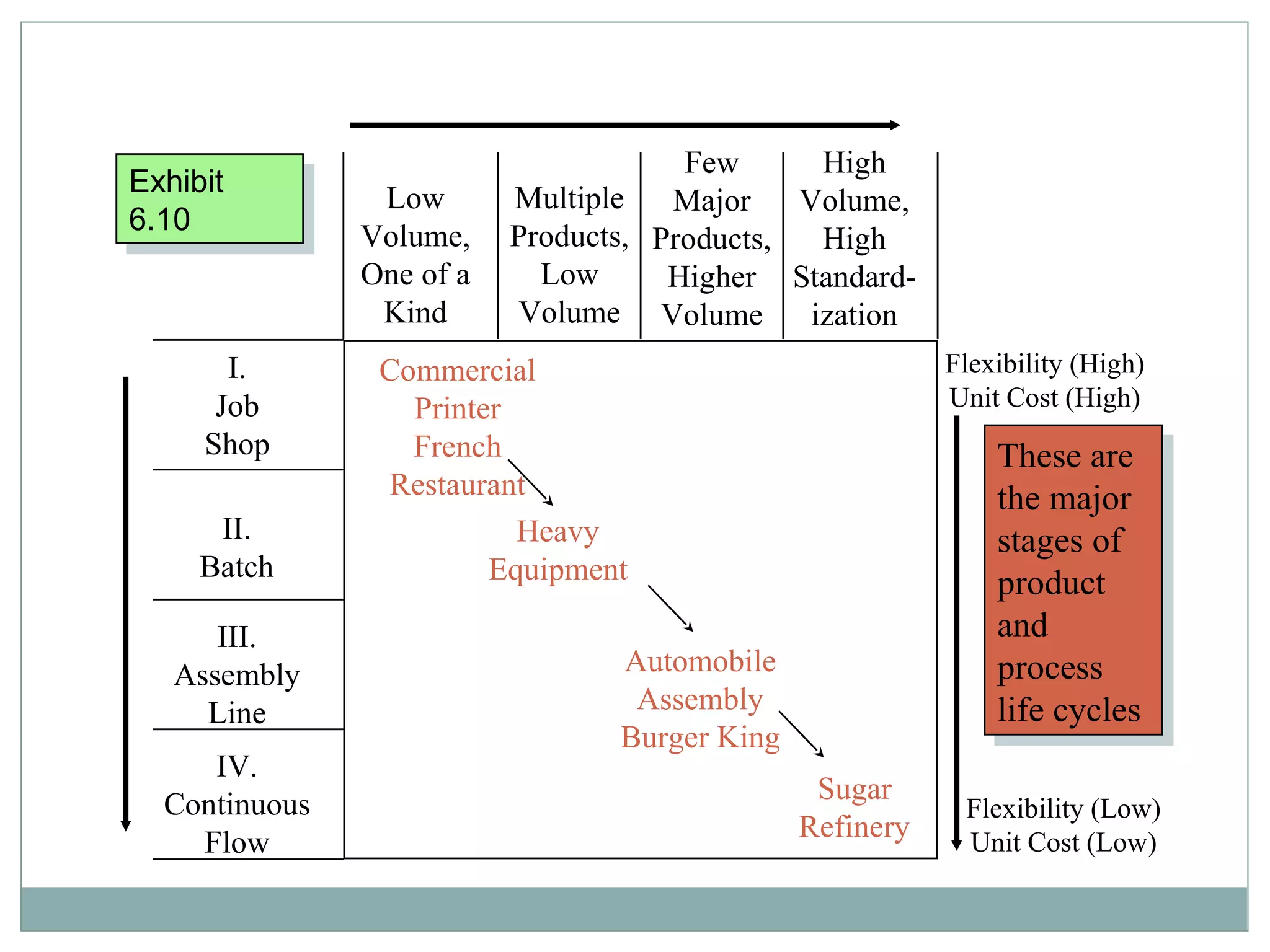

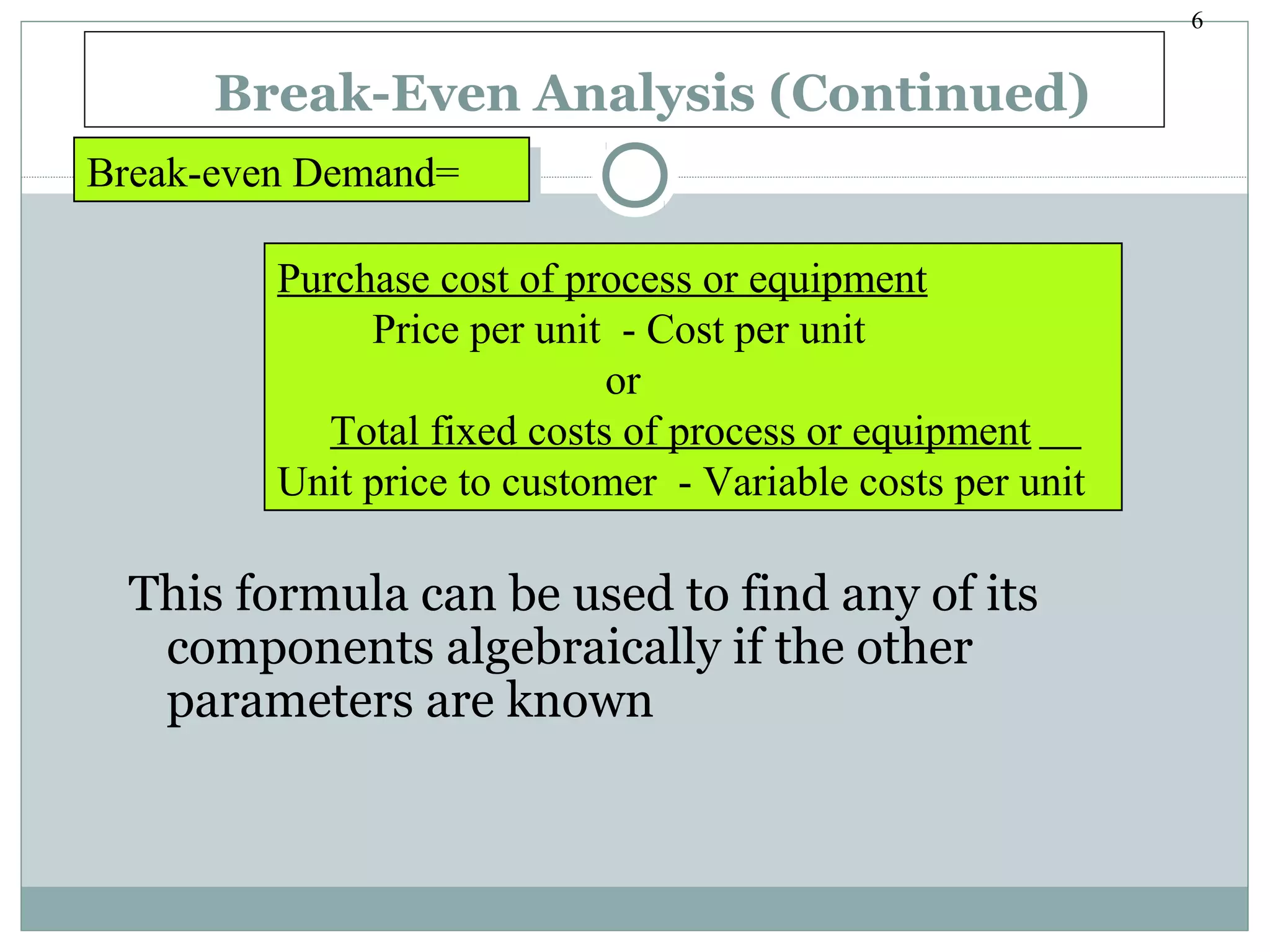

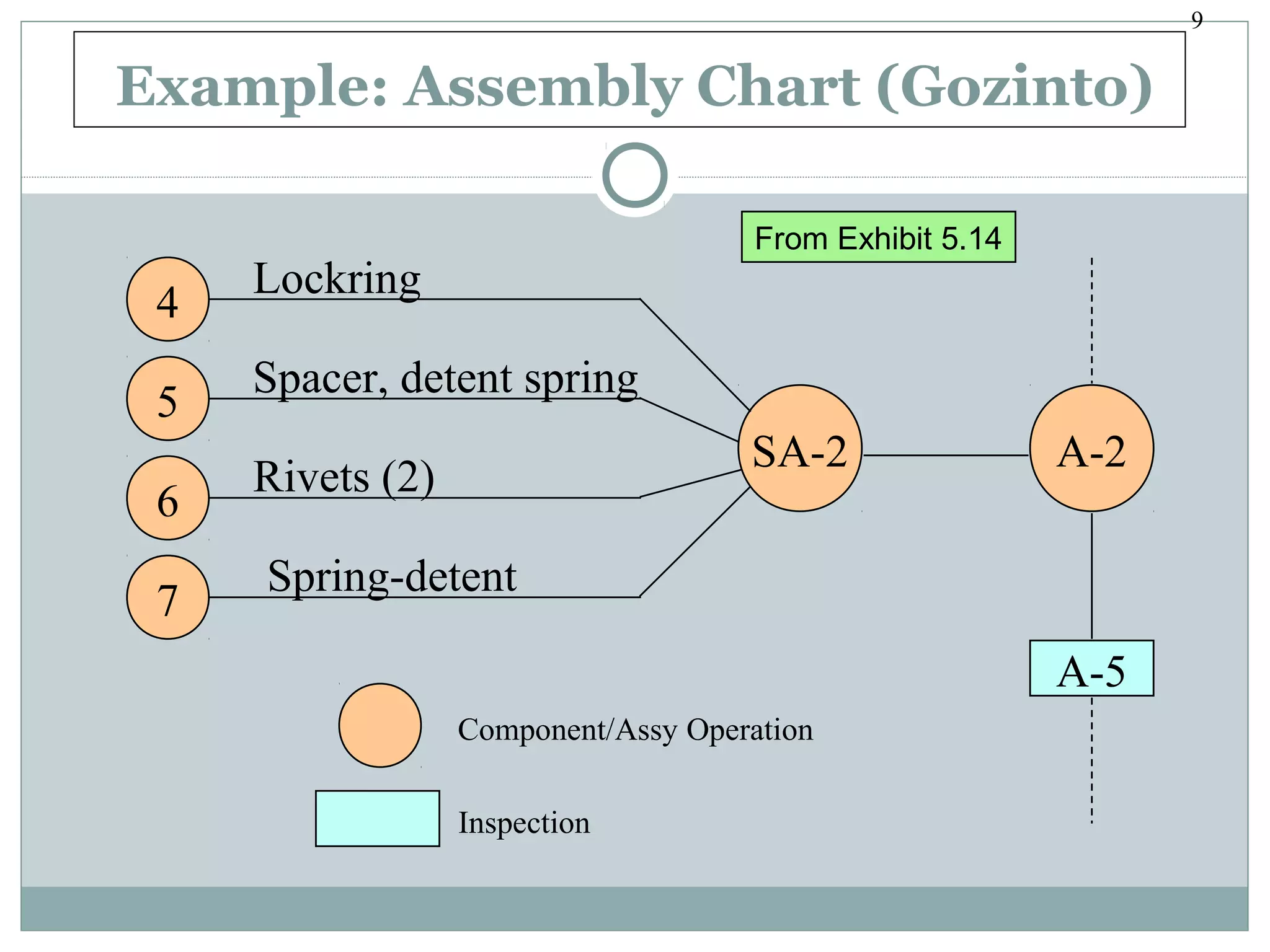

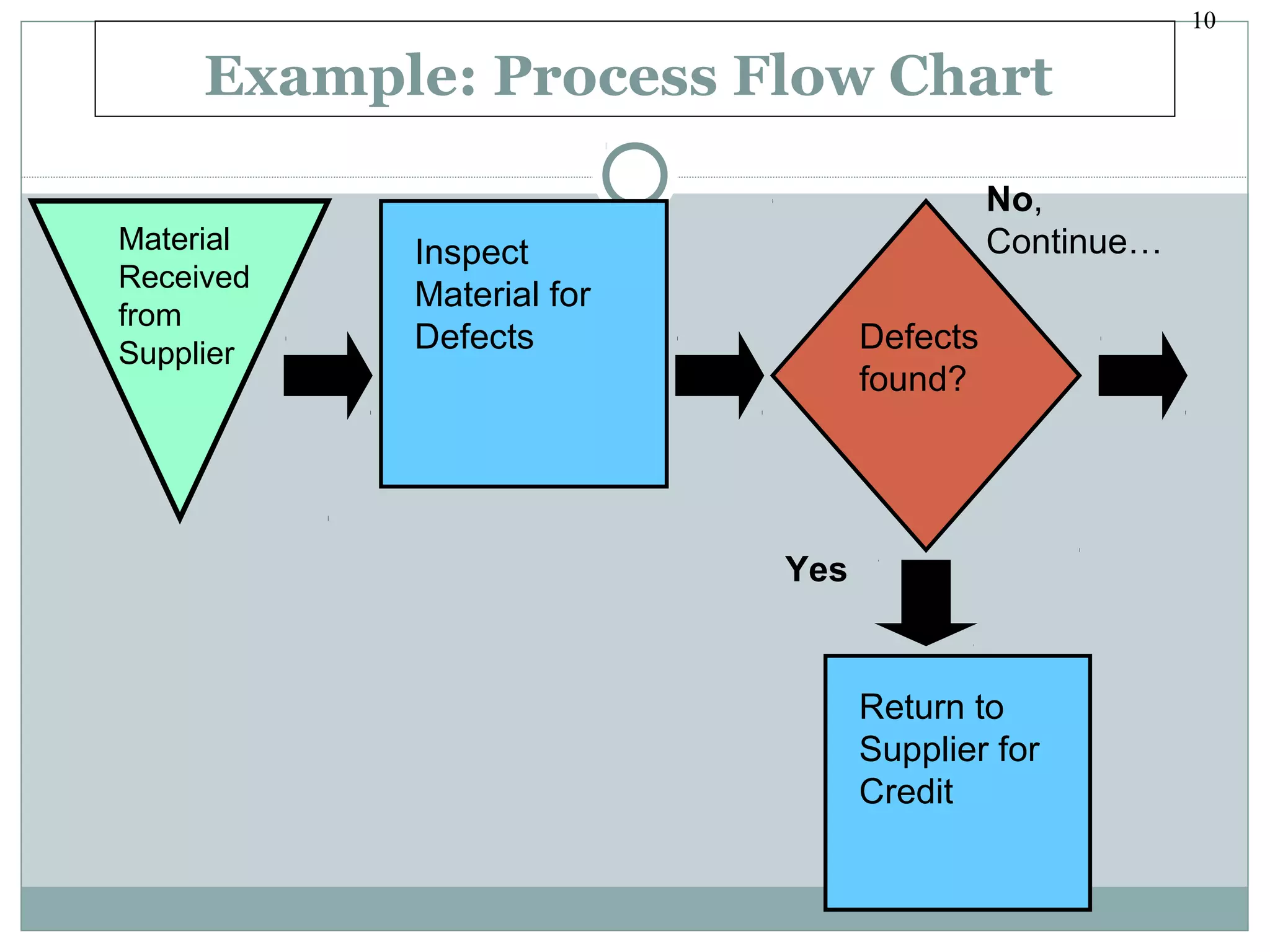

This document discusses manufacturing processes and process selection. It describes four main types of processes: conversion, fabrication, assembly, and testing. It then explains four common process flow structures used in manufacturing: job shop, batch shop, assembly line, and continuous flow. It provides examples of each structure. The document goes on to describe break-even analysis, a method to determine the production volume needed for a process to break even financially. It provides an example calculation. Finally, it defines manufacturing process flow design and lists common tools used, including assembly drawings, charts, and operation sheets, providing an example assembly chart.