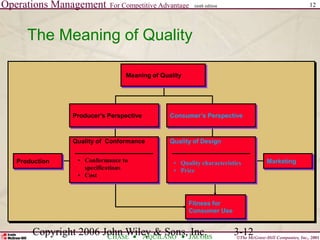

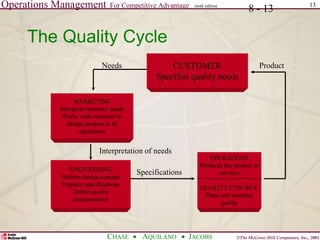

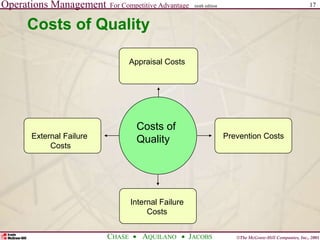

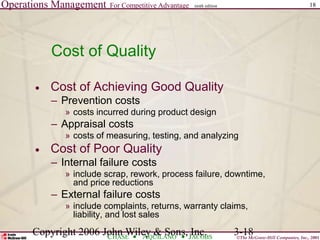

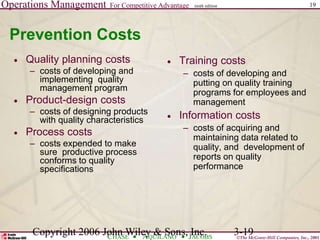

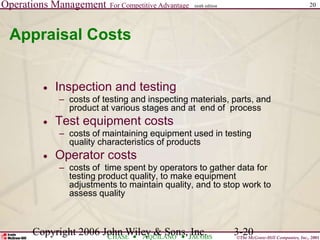

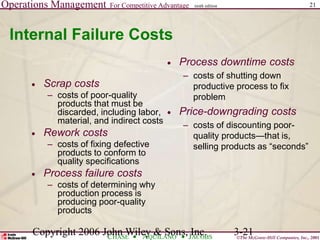

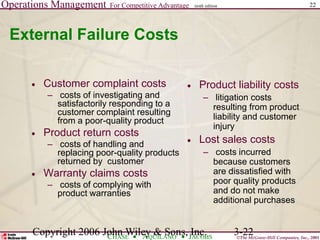

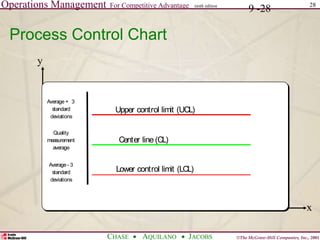

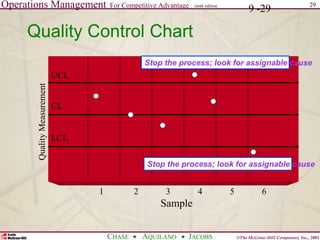

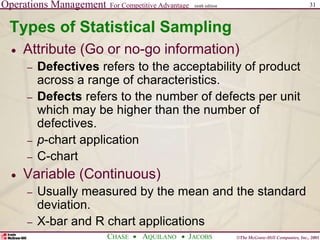

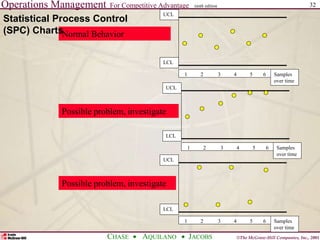

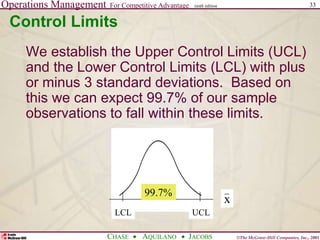

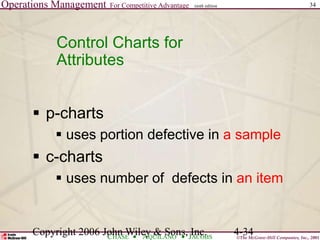

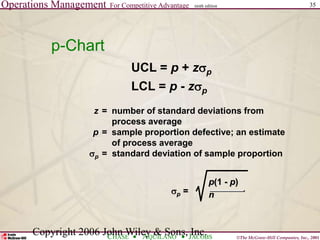

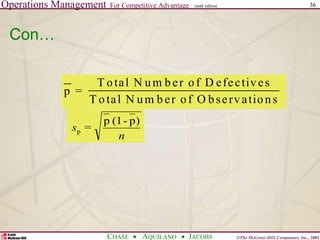

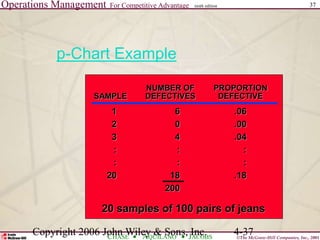

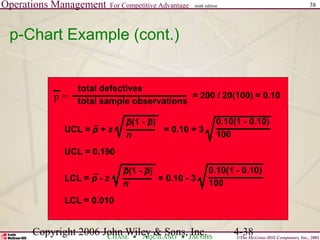

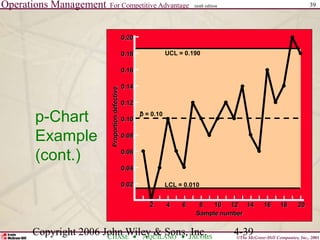

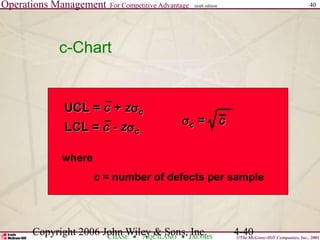

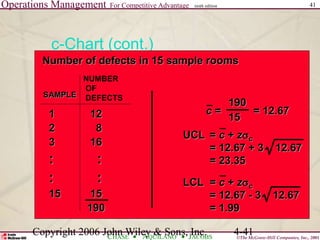

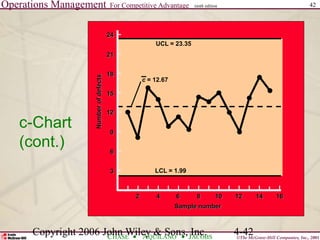

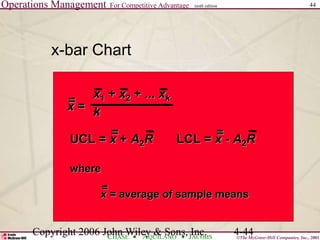

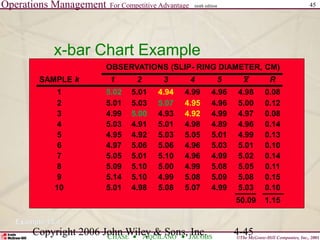

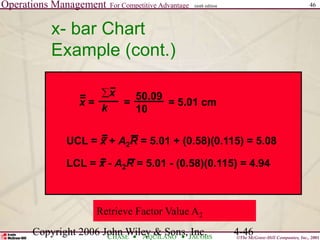

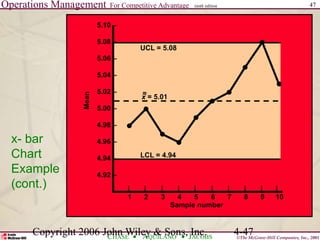

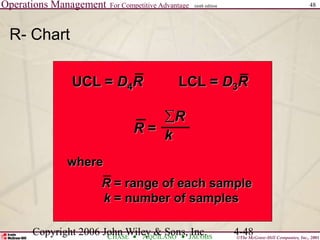

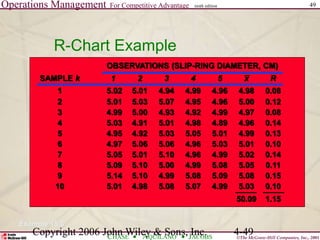

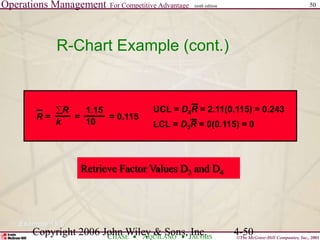

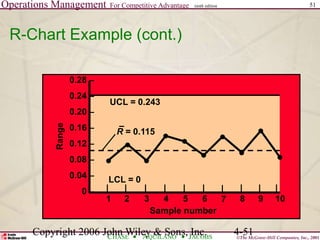

This document discusses quality management concepts including definitions of quality, dimensions of quality for manufacturing and services, costs of quality, statistical process control, and control charts. It defines total quality management and outlines its key principles. Quality is defined as meeting customer requirements now and in the future. Key dimensions of quality include quality of design, quality of conformance, and reliability. The costs of quality include prevention, appraisal, internal failure, and external failure costs. Statistical process control uses control charts to monitor processes and identify issues in need of corrective action.