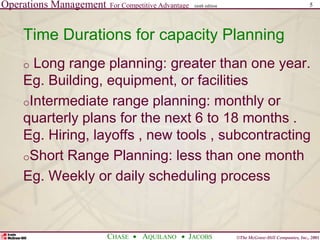

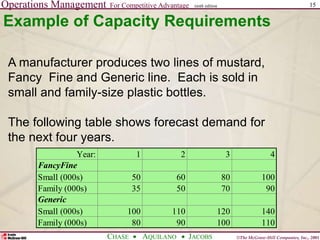

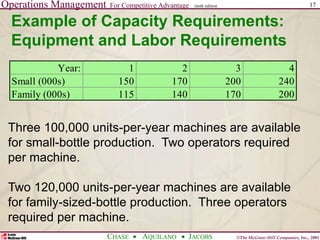

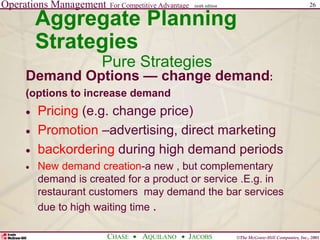

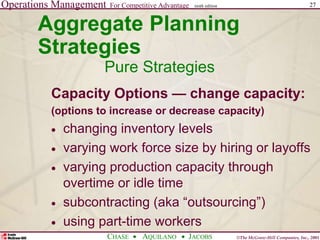

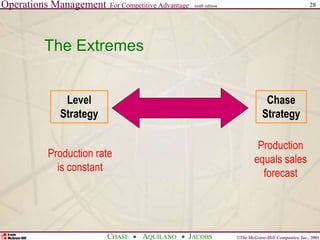

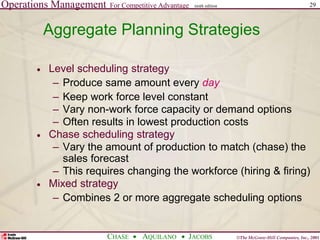

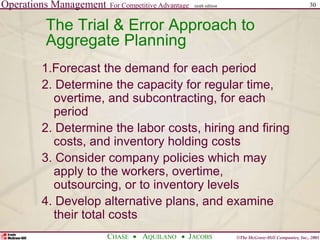

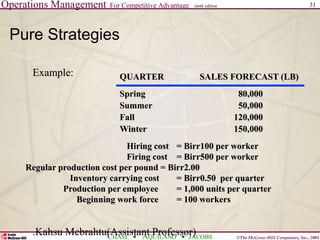

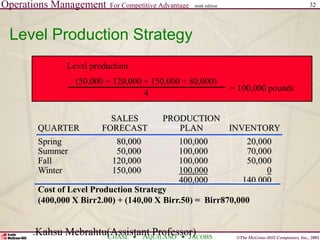

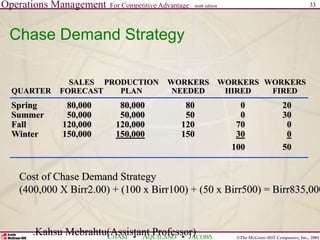

This document summarizes key concepts in operations management, specifically strategic capacity management, aggregate planning, and scheduling. It defines strategic capacity planning as determining a firm's overall level of capital-intensive resources like facilities and equipment. Aggregate planning aims to balance capacity and demand in a way that minimizes costs, considering labor, inventory, and other factors. The two main aggregate planning strategies discussed are the level strategy, where production is kept constant, and the chase strategy, where production varies to match demand forecasts. An example compares the costs of applying level versus chase strategies to a production problem.