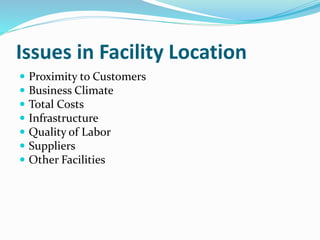

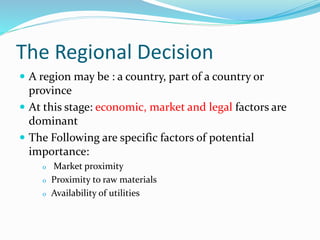

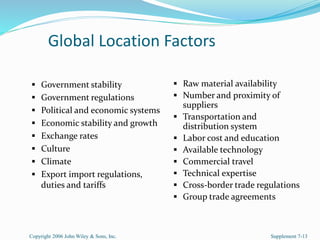

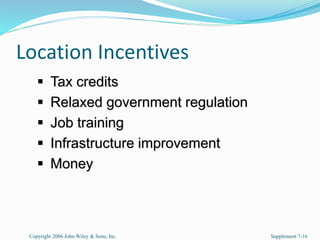

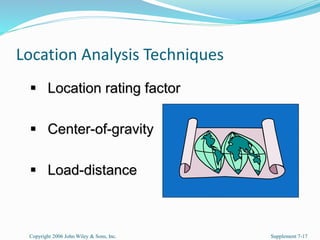

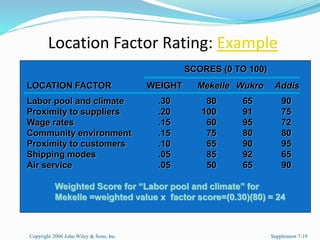

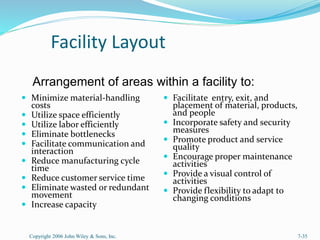

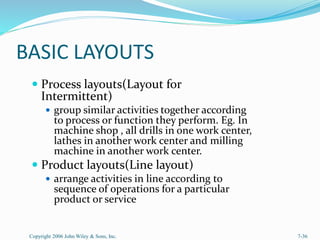

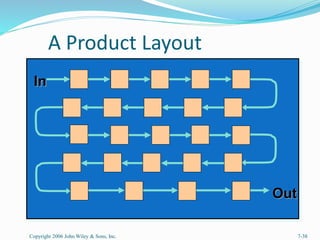

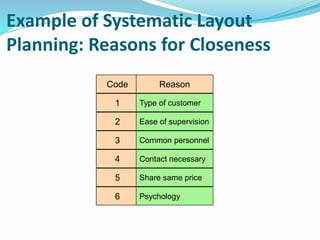

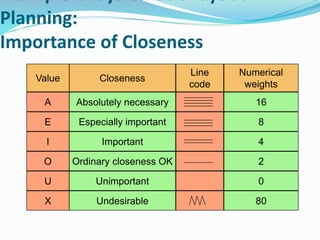

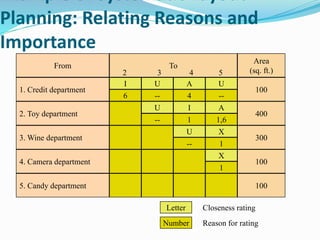

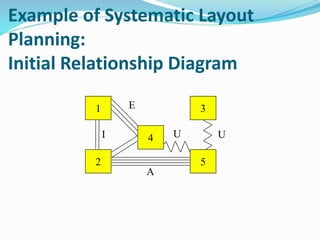

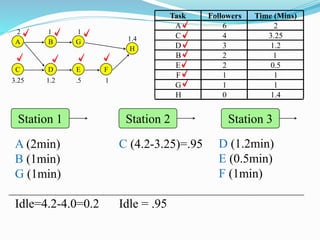

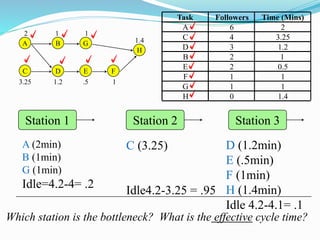

This document discusses facility location and facility layout. It begins by covering issues in facility location such as proximity to customers and suppliers, costs, infrastructure, and labor quality. It then describes three stages of the location decision process: regional, local, and site. Specific factors for each stage are provided. The document also discusses facility layout formats like process and product layouts. It covers layout planning techniques including systematic layout planning and assembly line balancing to optimize efficiency.