Here are pictures of 3 instruments from the laboratory pasted onto the notebook page with descriptions:

[PASTE OR PRINT PICTURES HERE WITH CAPTIONS]

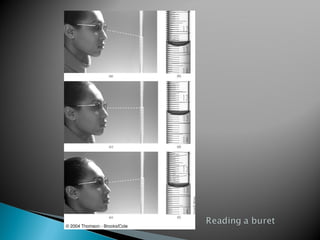

Buret: Used for precise volumetric measurements in titration experiments. Has graduations that allow measurement to within 0.1 mL.

Analytical balance: Used to measure small masses with high precision, down to 0.1 mg. Important for quantitative chemical analysis and synthesis.

Beaker: Common glassware for mixing, heating, and containing solutions in a variety of volumes. Often used for reaction mixtures and titration procedures.