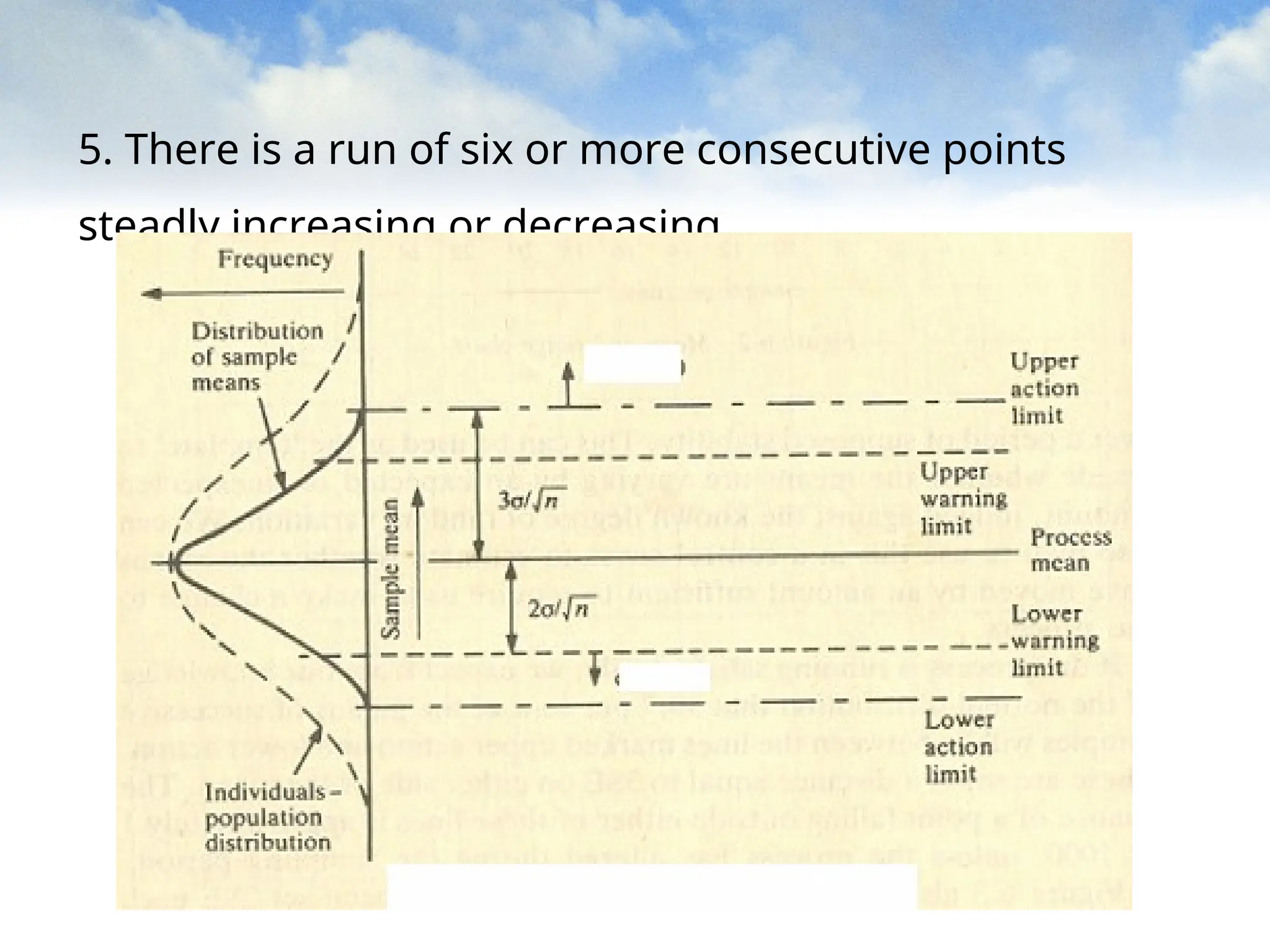

Chapter four discusses statistical quality control (SQC), describing it as a set of statistical tools for quality management to address limitations of inspection. It highlights the importance of monitoring process variations, both common and assignable, and introduces statistical process control (SPC) as a method to maintain quality during production. The chapter emphasizes the use of control charts for monitoring processes and outlines guidelines for implementing SPC effectively.