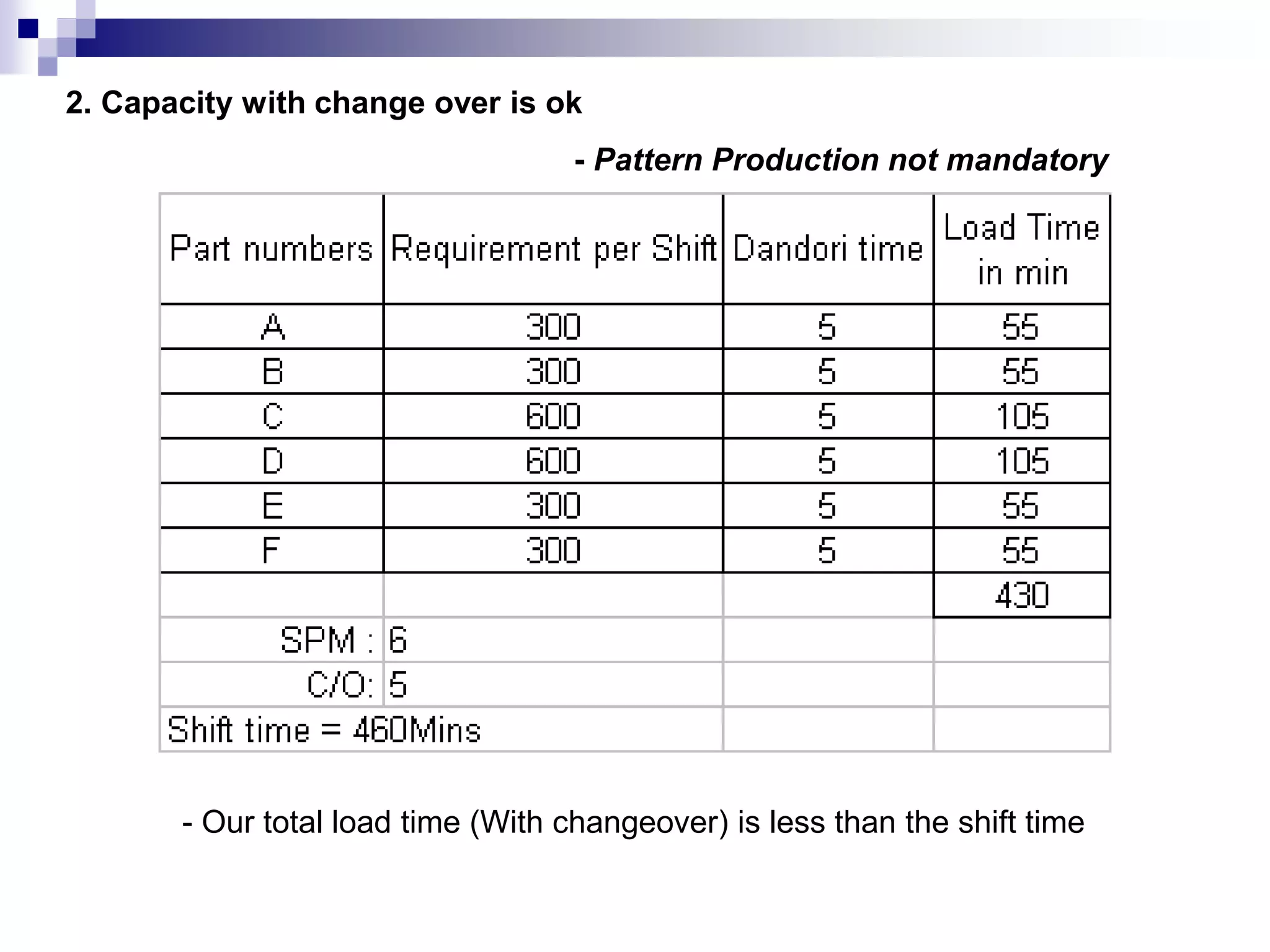

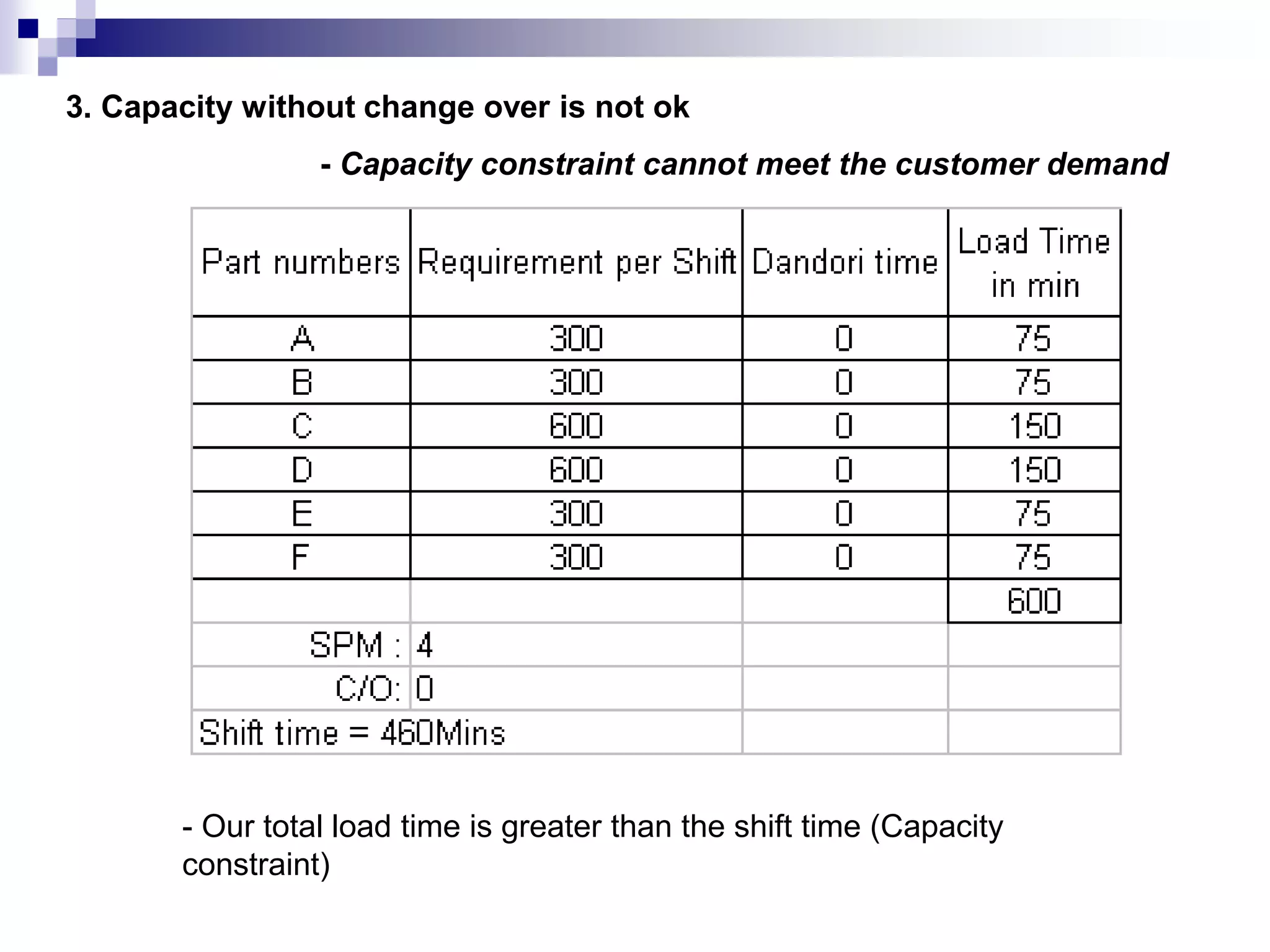

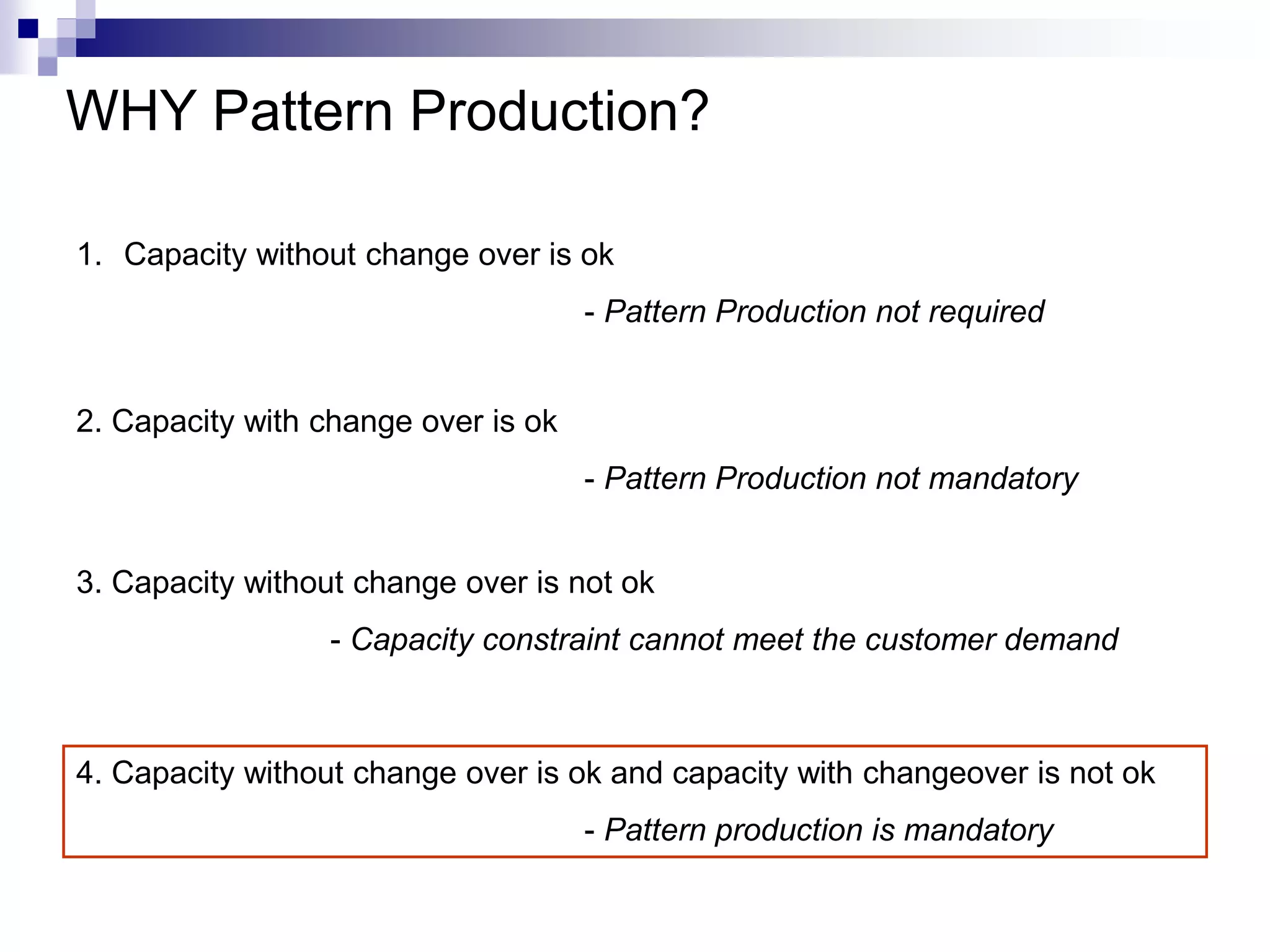

Pattern production is a production scheduling method where a fixed sequence of parts is produced. It has two basic principles: fixed time variable quantity, where production time is fixed but quantity may vary, and fixed quantity variable time, where quantity is fixed but production time may vary. Pattern production is necessary when capacity constraints exist that prevent meeting customer demand without it, such as when capacity is okay without changeovers but not with changeovers. Benefits include effective resource utilization, elimination of daily planning and unplanned overtime, and minimized production variation.