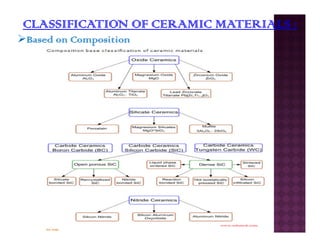

Ceramic materials are inorganic, non-metallic compounds made by applying heat to mixtures of metals and non-metals like clay and sand. Common ceramic materials include aluminum oxide, zirconium oxide, silicon nitride, boron nitride, silicon carbide, and boron carbide. Each has different properties making them suitable for various applications like machine components, bearings, cutting tools, and armor. Silicate ceramics like porcelain, magnesium silicate, and mullite are also described.

![ALUMINUM OXIDE [Al2O3]

Aluminum oxide is the most widely applied ceramic type,

often used as electrical insulator and for wear-resistant

applications. The material is available in several grades.

PROPERTIES

•Electrical insulator

•Wear resistant

•Extremely heat resistant

•High stiffness , high purity.

•Melting point – 2050 *C.

•Density – 4.0 g/cm^3 .

•Strength – 455 Mpa .

•Co-efficient of thermal expansion – 8*10-6/*C .

•Thermal conductivity – 40 (W/mK) .

•Elastic modulus – 380 Gpa.

APPLICATIONS

•Machine components

•Machine and equipment](https://image.slidesharecdn.com/ceramicmateraials-151219204252/85/Ceramic-materaials-5-320.jpg)

![ZIRCONIUM OXIDE [ZrO2 ]

Of all types of ceramics, the properties of zirconium

oxide lie the closest to those of metals. The material is

less wear-resistant than e.g. silicon carbide or silicon

nitride. On the other hand: zirconium oxide is quite tough

and impact resistant

PROPERTIES

•Impact resistant .

•Low thermal conductor .

•High flexural strength .

•Toughness .

•Mechanically strong .

•Electrical insulators .

•Melting point – 2700 ºC.

•Density – 5.6 g/cm3 .

•Strength –175 Mpa.

•Co-efficient of thermal expansion – 10.5*10-6/ºc.

•Thermal conductivity – 19(W/mK).

•Elastic modulus – 140 Gpa.](https://image.slidesharecdn.com/ceramicmateraials-151219204252/85/Ceramic-materaials-6-320.jpg)

![SILICON NITRIDE [Si3N4]

Due to its crystal structure, silicon nitride is one of the

toughest ceramic materials. Furthermore it has a very

good thermal shock resistance and good tribiological

properties.

PROPERTIES

• High wear resistant

• Stiffness

• Chemical resistant

•Thermo shock resistant

• Electrical insulator or conductor

• Low expansion coefficient

•Melting point – 1900 *C.

•Density – 3.2g/cm^3 .

•Strength – 210 Mpa.

•Co-efficient of thermal expansion – 3.0*10-6/ºc

•Thermal conductivity – 17(W/mK).

•Elastic modulus – 175Gpa](https://image.slidesharecdn.com/ceramicmateraials-151219204252/85/Ceramic-materaials-8-320.jpg)

![BORON NITRIDE [BN]

Boron nitride in the hexagonal crystal structure can be best

compared with graphite. Contrary to other types of ceramics,

this material is soft. Due to its high temperature resistance,

boron nitride is used often in the non-ferro industry.

PROPERTIES

•Good machinability

•Extremely heat resistant thermo shock resistant

•Electrical insulator

APPLICATION

•Lubricating

•Isolating

•Wear-resistant

•Positioning](https://image.slidesharecdn.com/ceramicmateraials-151219204252/85/Ceramic-materaials-10-320.jpg)

![SILICON CARBIDE [SIC]

Silicon carbide consists of the chemical elements silicon

(like in sand) and carbon, and is very hard. Due to the

good chemical resistance, silicon carbide can be applied

very well under extreme conditions.

PROPERTIES

•High stiffness

•High thermal conductor

•Chemical resistant

•Thermo shock resistant

•Low density

•Wear resistant

•Melting point – 2700 *C.

•Density – 3.2g/cm^3 .

•Strength – 140 Mpa.

•Co-efficient of thermal expansion – 4.3*10-6/º c

•Thermal conductivity – 50(W/mK).

•Elastic modulus – 210Gpa](https://image.slidesharecdn.com/ceramicmateraials-151219204252/85/Ceramic-materaials-11-320.jpg)

![BORON CARBIDE [B4C]

Boron carbide is an extremely hard ceramic with a

low weight. This makes the material greatly useful

for ballistic applications.

PROPERTIES

•Hardness

•Wear resistant

•Lightweight

•Melting point – 2350 *C.

•Density – 2.5g/cm^3 .

•Strength – 350 Mpa.

•Co-efficient of thermal expansion – 4.3*10-6/ºcThermal

conductivity – 25(W/mK).

•Elastic modulus – 450Gpa](https://image.slidesharecdn.com/ceramicmateraials-151219204252/85/Ceramic-materaials-13-320.jpg)