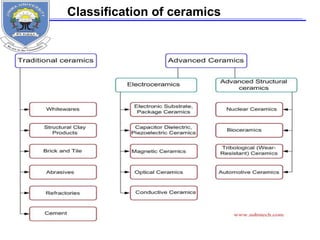

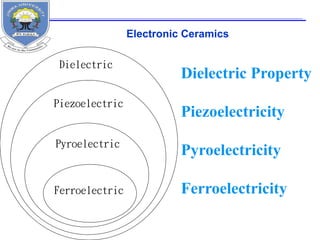

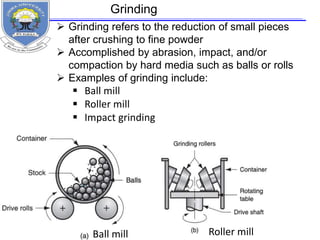

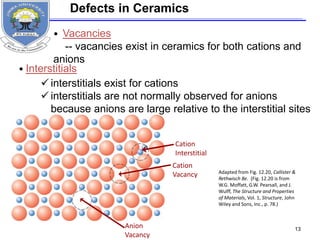

This document provides information on the properties of ceramics. It begins with an introduction to ceramics, including their atomic bonding and crystal structures. It then discusses defects in ceramics and general properties such as brittleness, toughness, and strength at high temperatures. The document classifies ceramics and discusses properties and applications of various types, including electronic ceramics like piezoelectric and dielectric ceramics. Processing methods are also briefly mentioned.

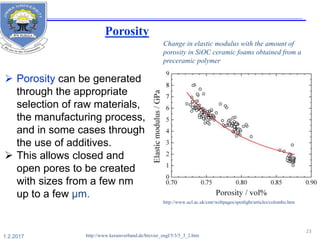

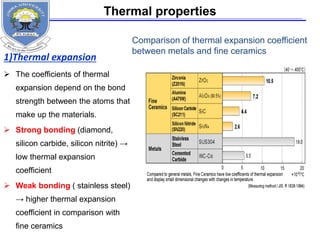

![Elastic modulus

The elastic modulus E [GPa]

of almost all oxide and non-

oxide ceramics is consistently

higher than that of steel.

This results in an elastic

deformation of only about 50

to 70 % of what is found in

steel components.

http://www.keramverband.de/brevier_engl/5/3/4/5_3_4.htm](https://image.slidesharecdn.com/fayzaceramics-170201145338/85/Fayza-ceramics-20-320.jpg)