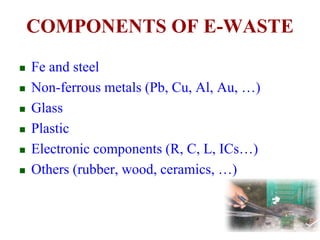

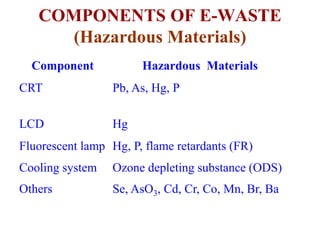

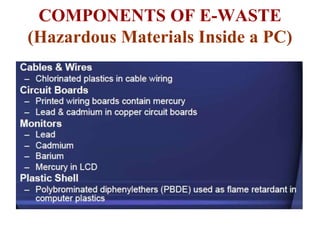

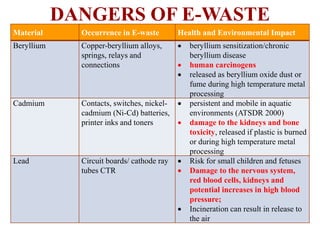

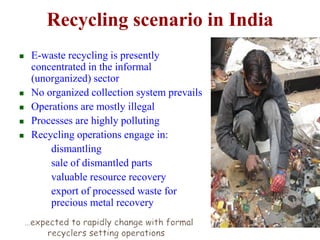

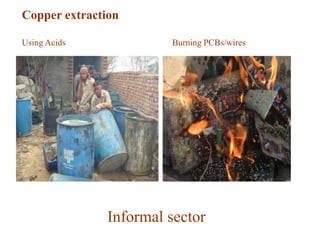

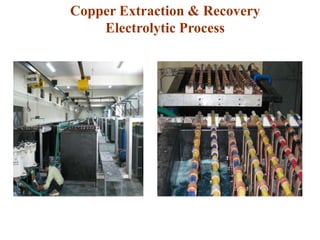

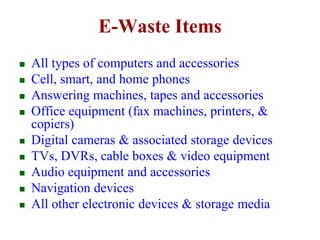

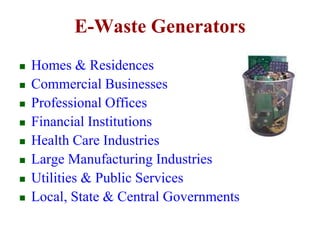

This document discusses e-waste management. It defines e-waste as obsolete electronic devices, outlines its various components and generators. E-waste is growing rapidly due to technology obsolescence and contains toxic materials like lead, cadmium and mercury. Most e-waste in India is handled by the informal sector using dangerous practices, while formal recycling is increasing. Effective e-waste management requires an integrated approach between informal and formal sectors along with policies, collection systems and public awareness.

![Background

Obsolescence of technology: outdated within 18

months

Upcoming analog to digital conversion

Electronic Waste [Waste EEE (Electric, Electronic

Equipment)] one of the fast growing waste streams

all over the world

E-waste has been identified as the fastest growing

waste stream in the world; forecast to soon reach 40

million tonnes a year.

The European Environment Agency has calculated

that the volume of e-waste is rising about three times

faster than any other form of municipal waste.](https://image.slidesharecdn.com/ce-105e-waste-ce105vcs-140930114034-phpapp02/85/Ce-105-e-waste-ce-105vcs-6-320.jpg)