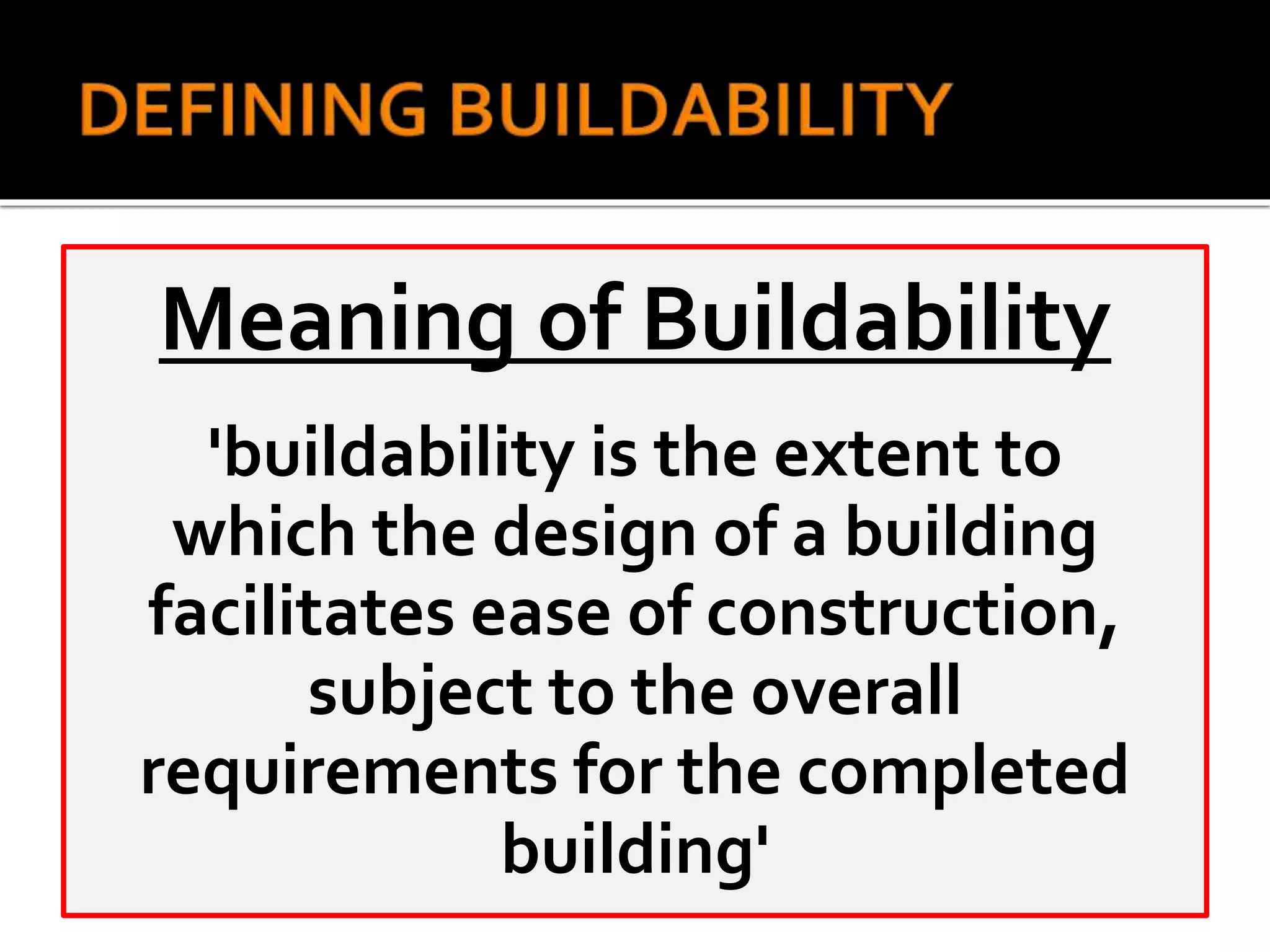

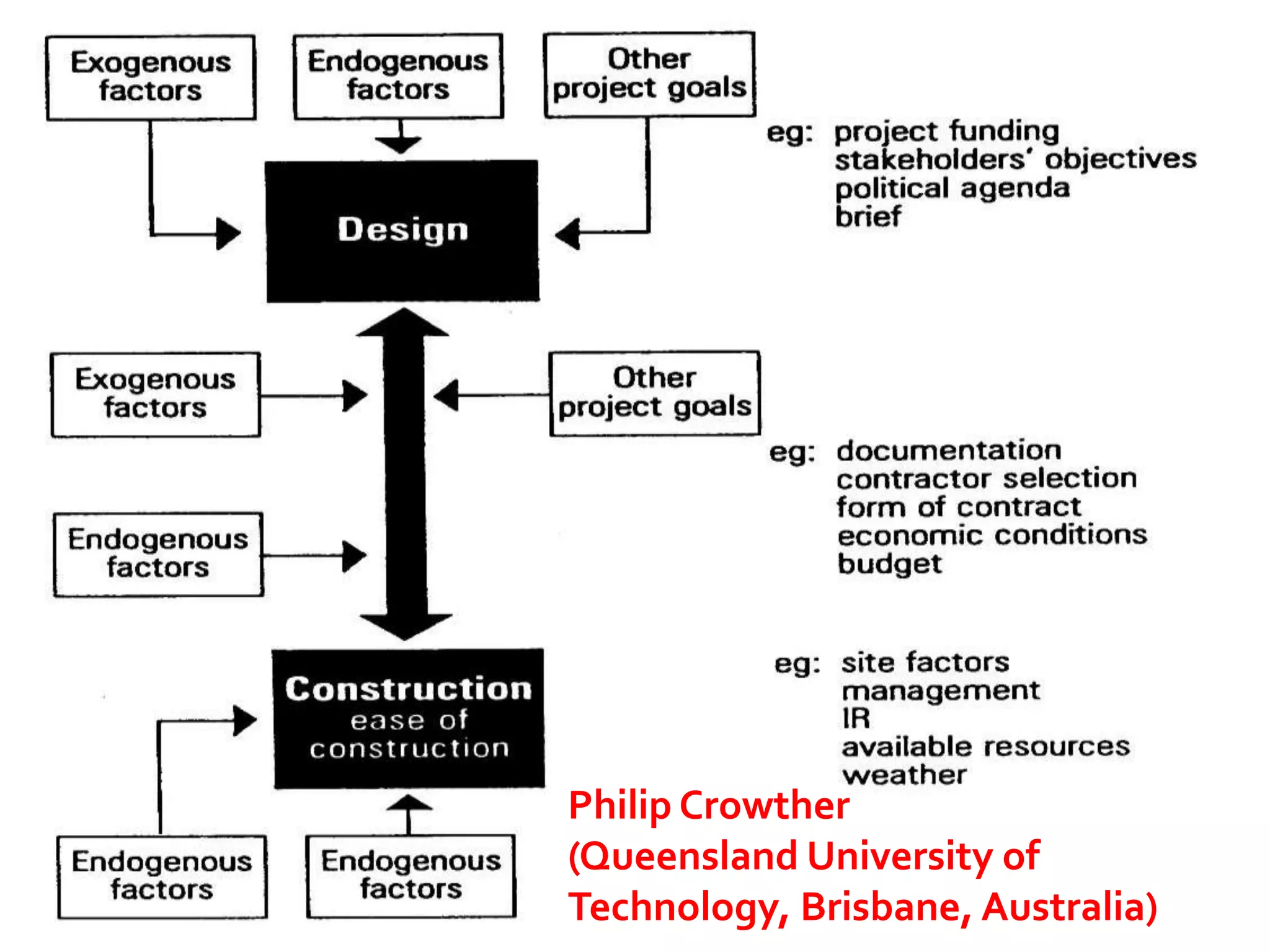

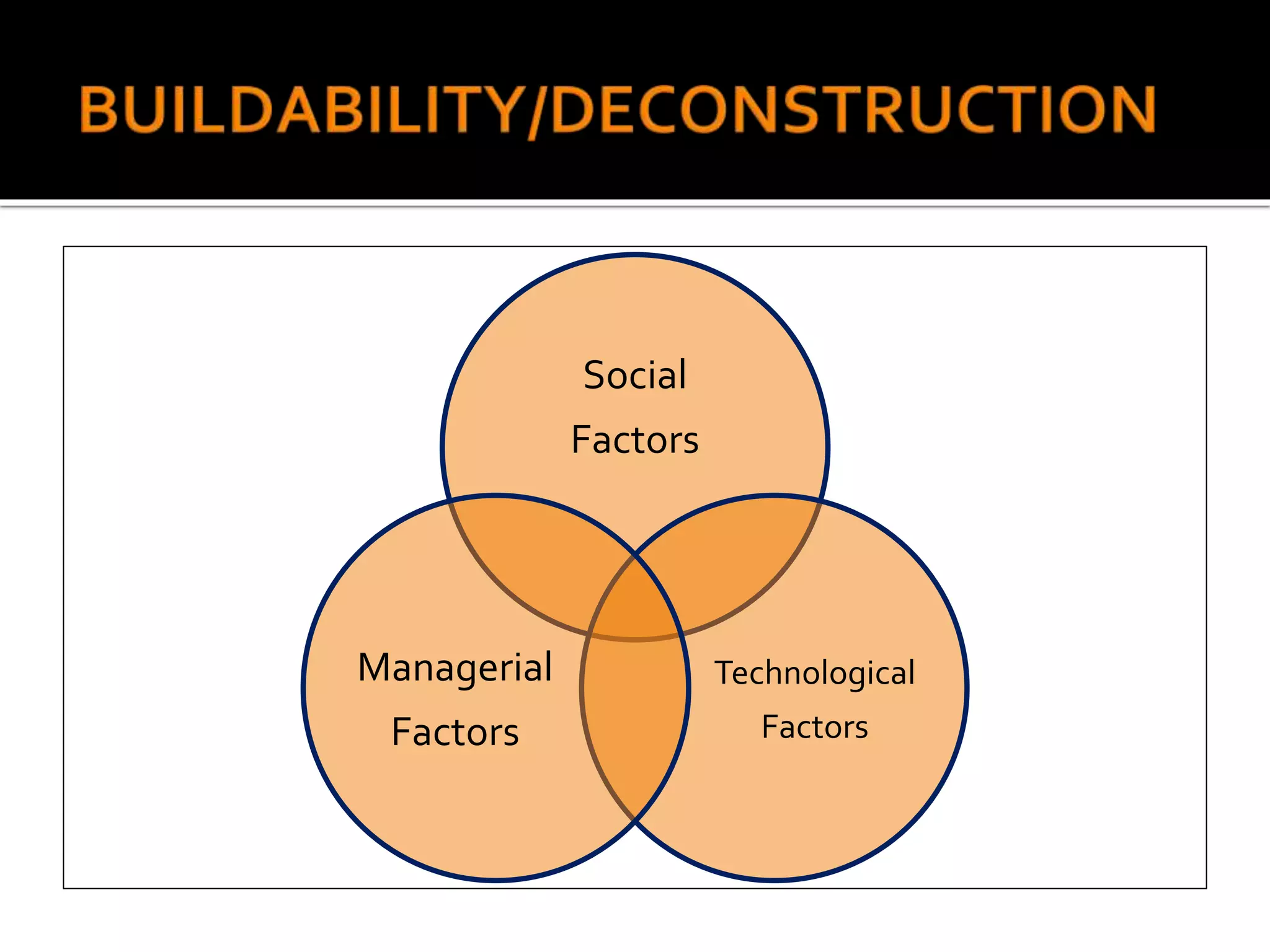

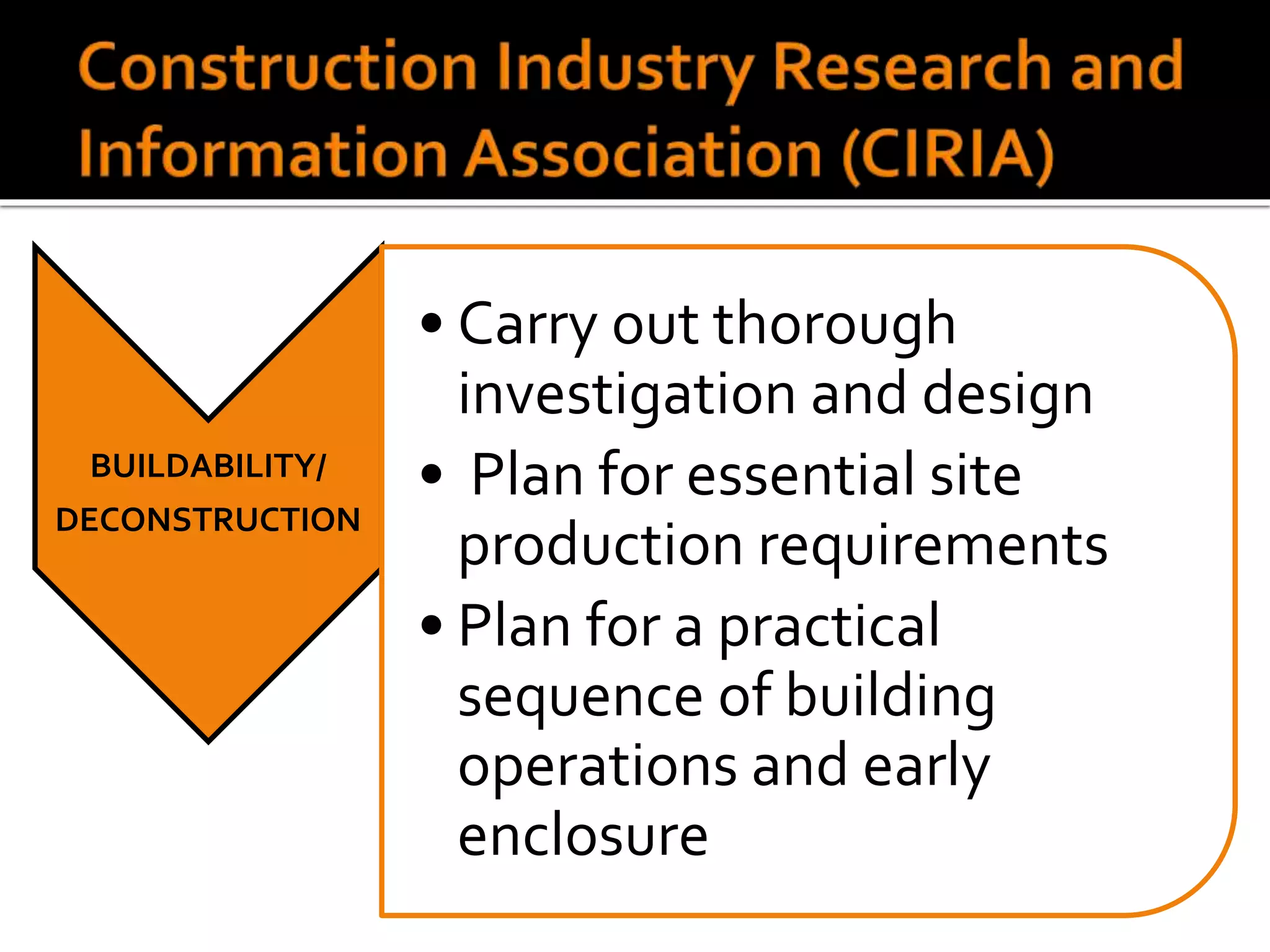

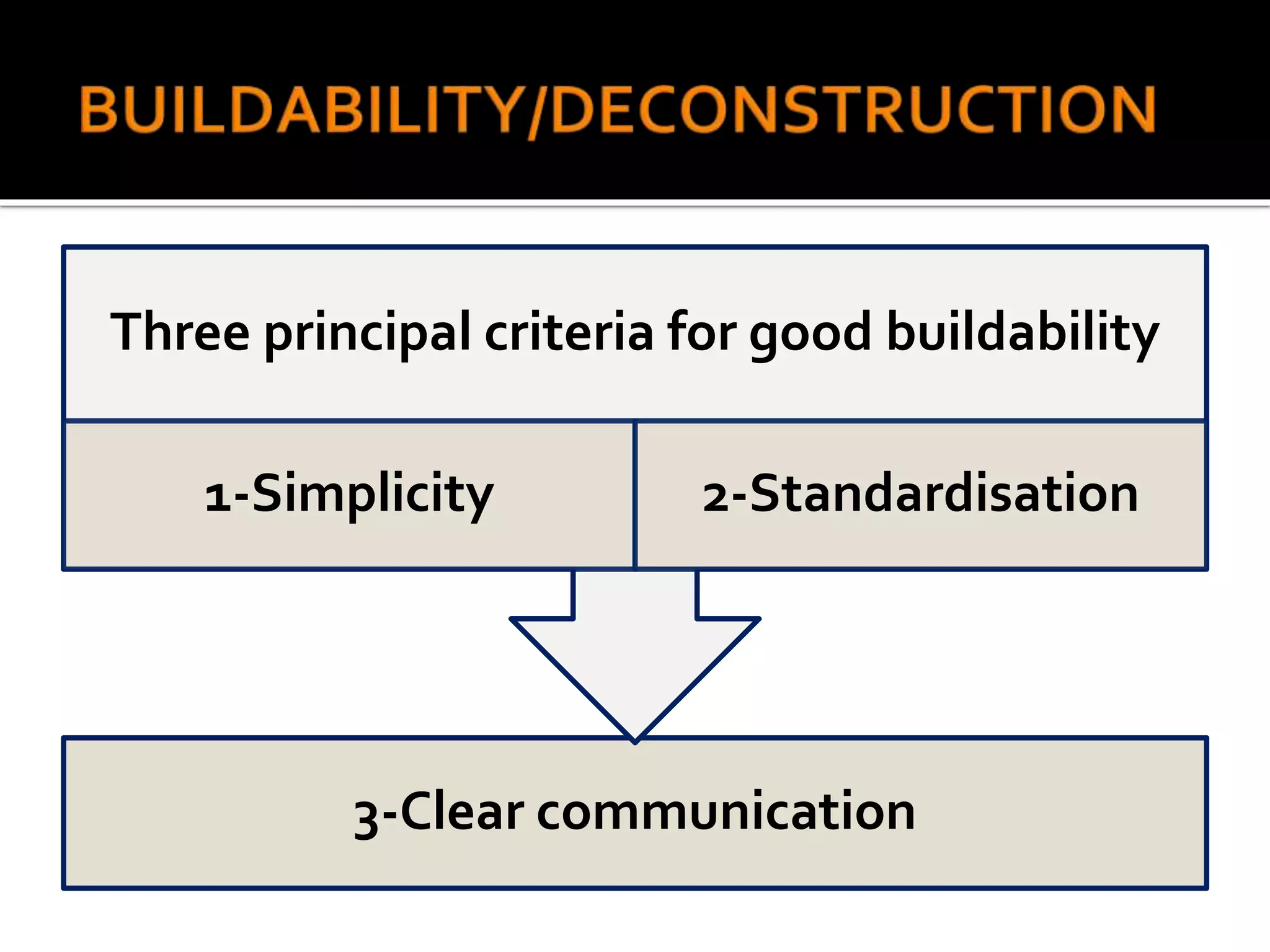

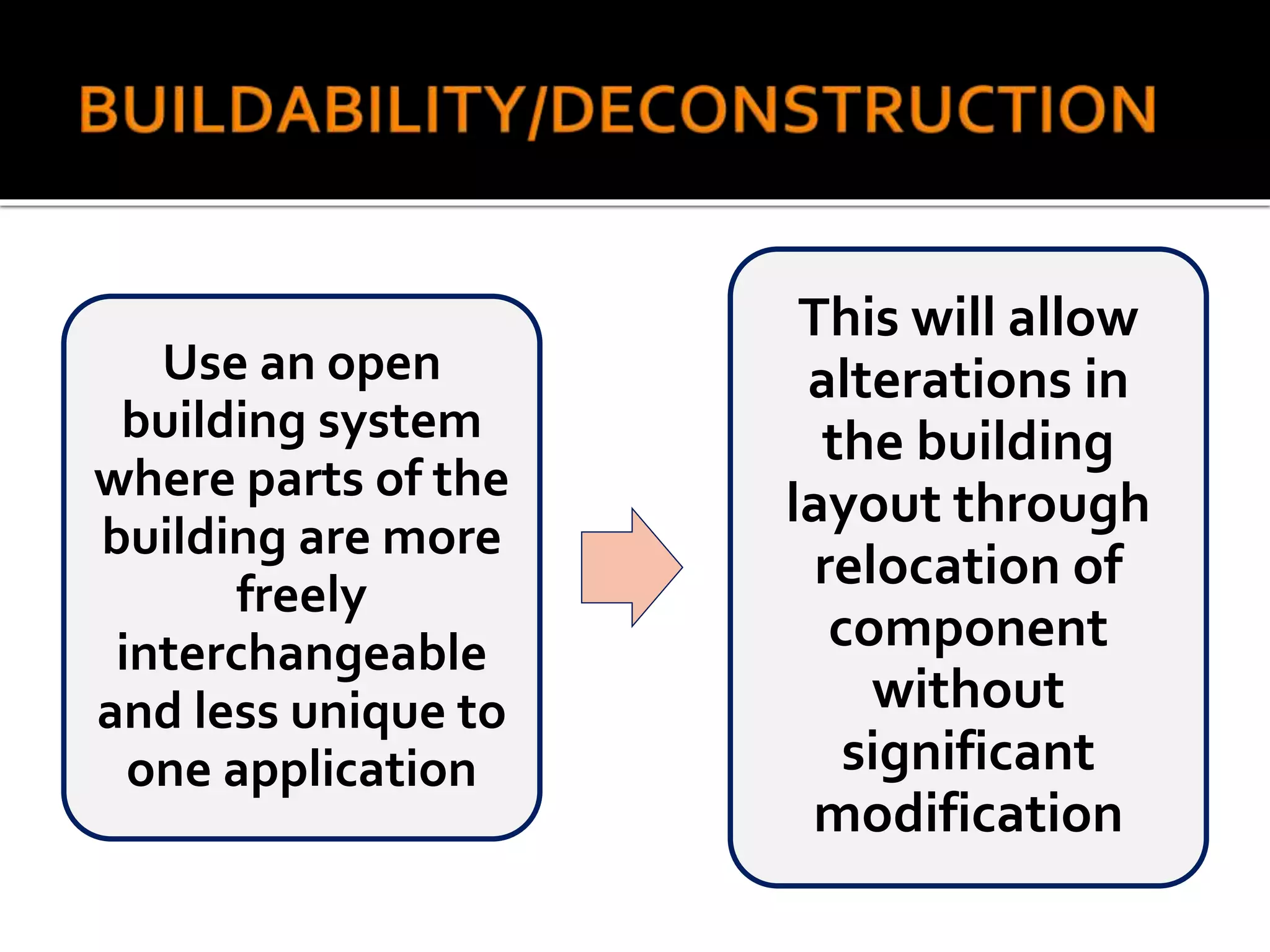

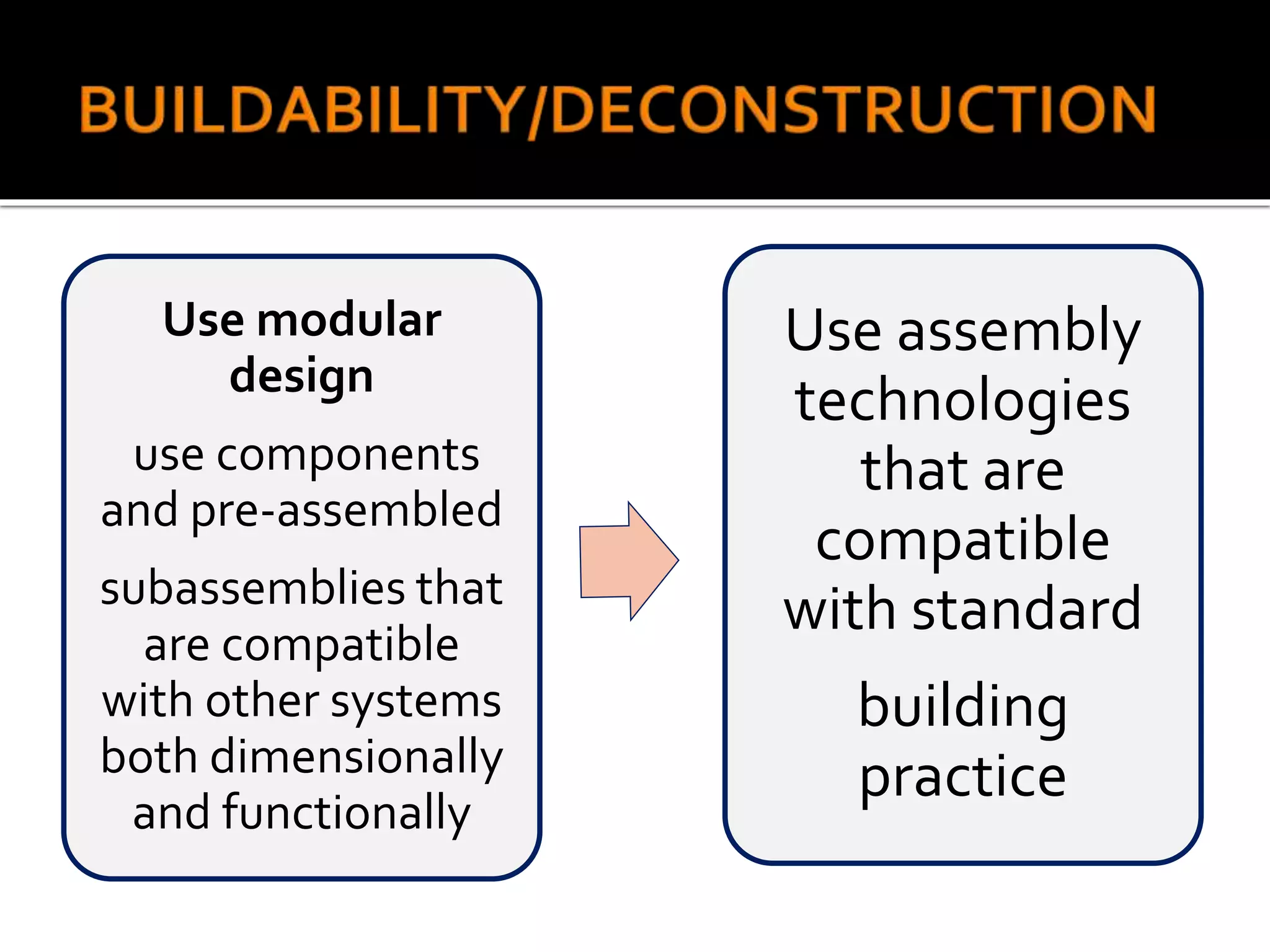

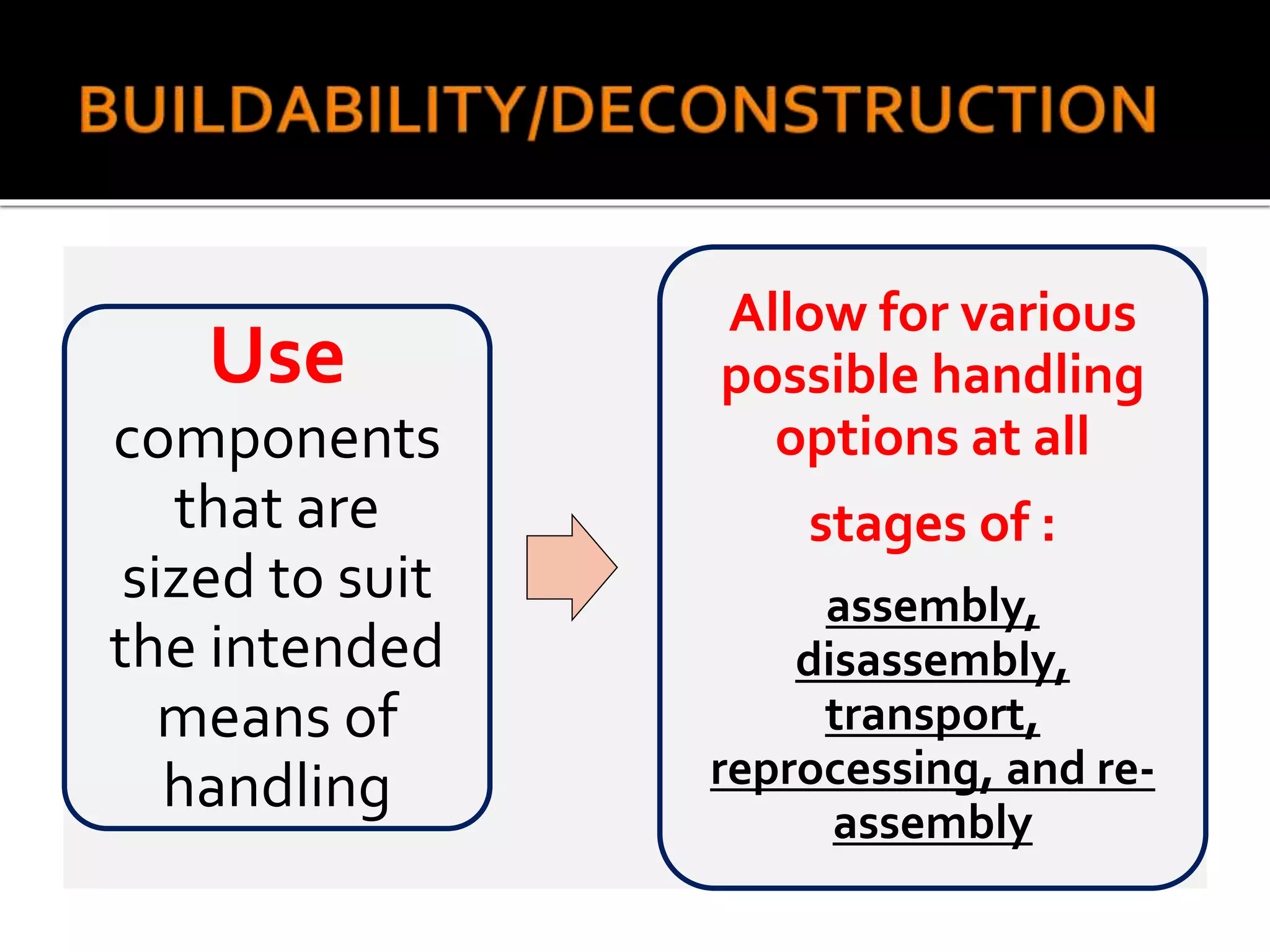

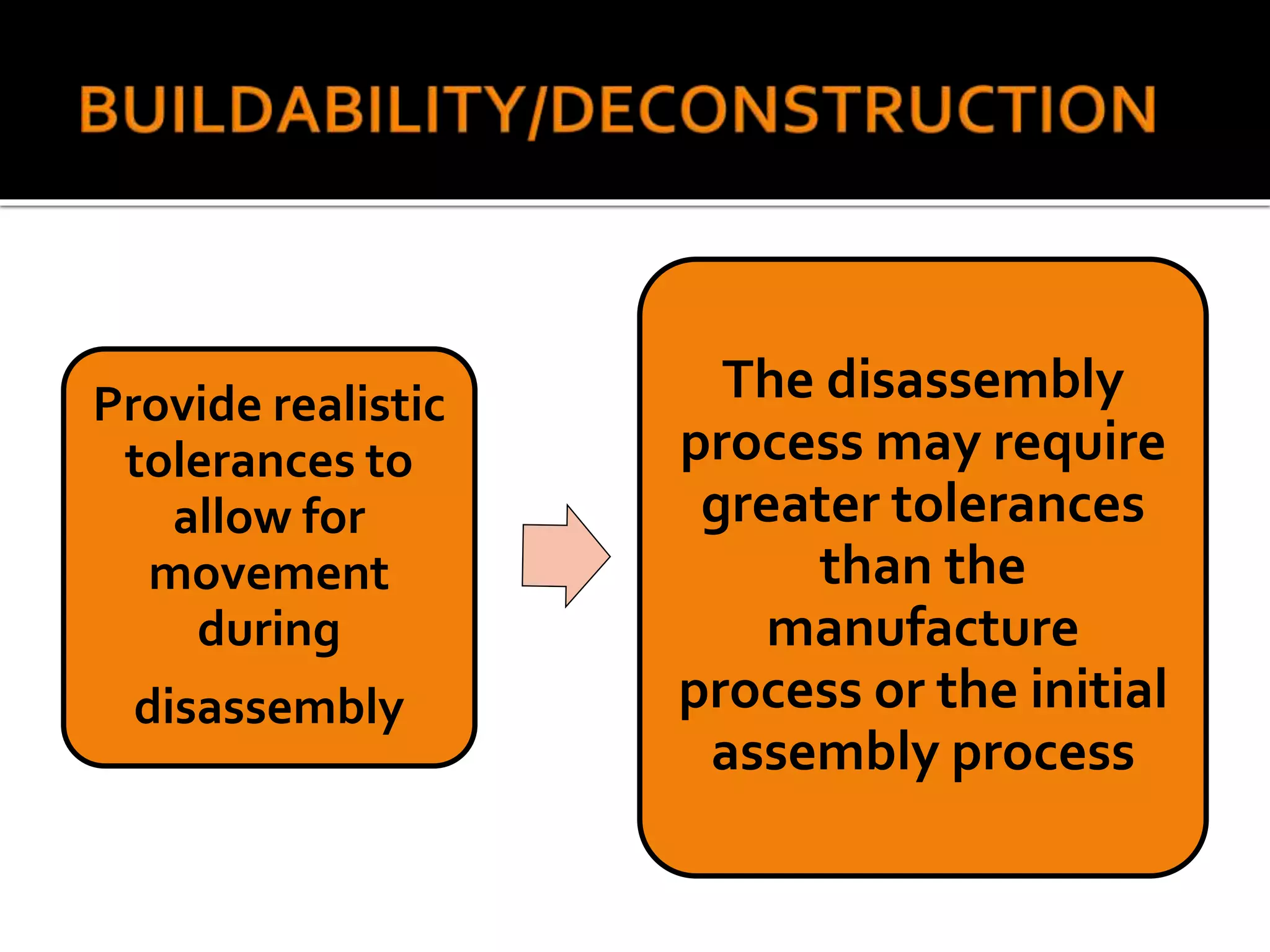

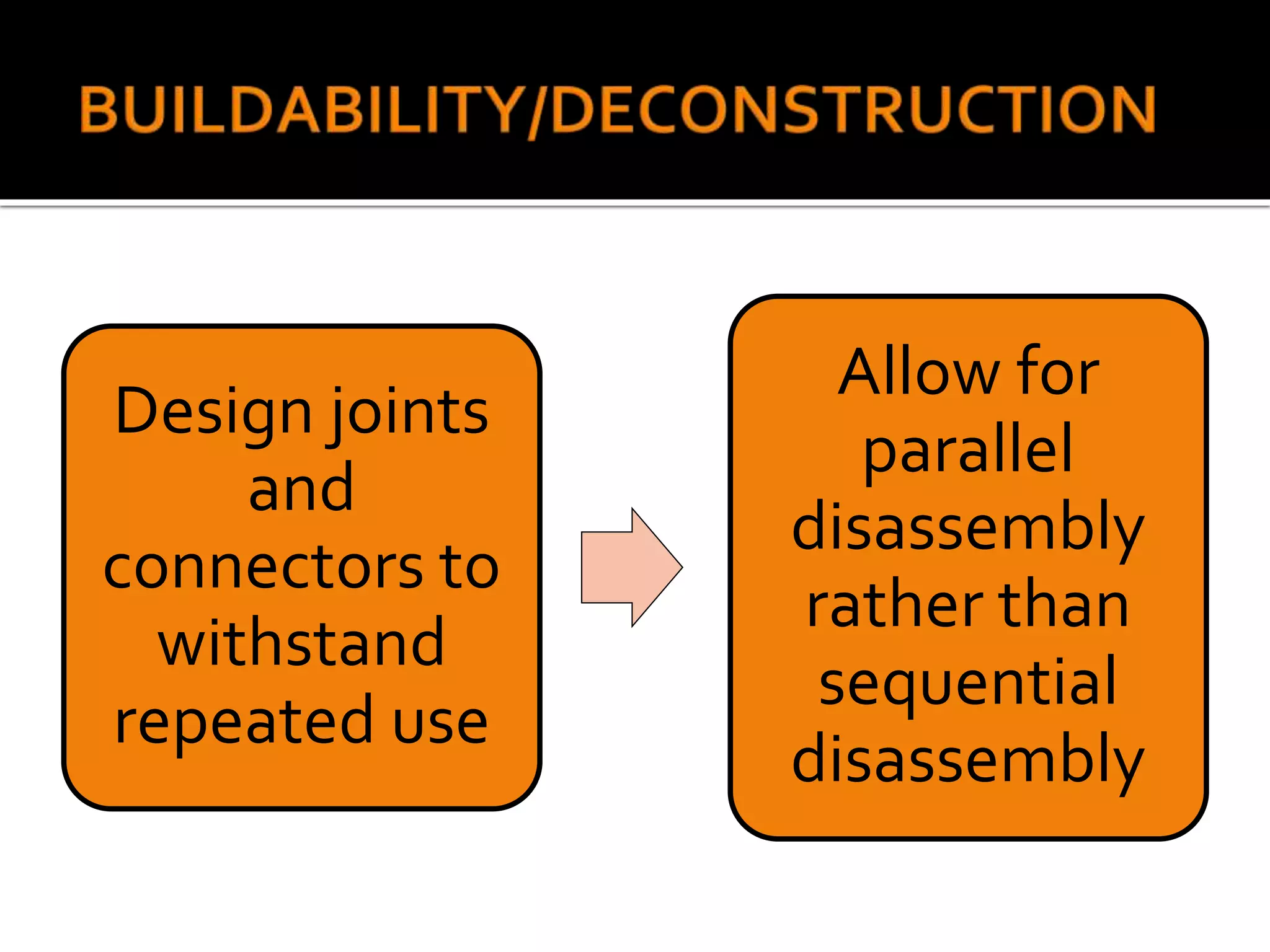

The document discusses design for disassembly and how principles of buildability can inform it. It provides background on buildability research and identifies some of the key principles of buildability, such as simplicity, standardization, and clear communication. It then examines how some buildability principles can be applied to design for disassembly, such as minimizing component types, using modular designs, and ensuring accessibility to all parts of the building.