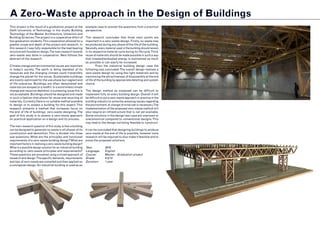

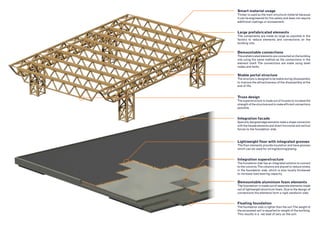

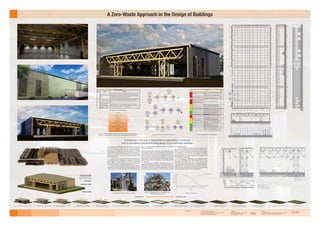

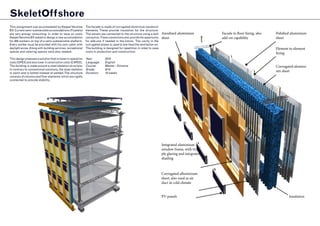

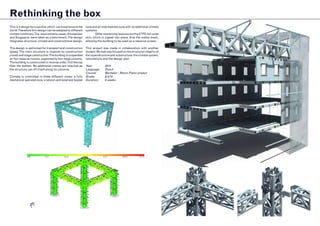

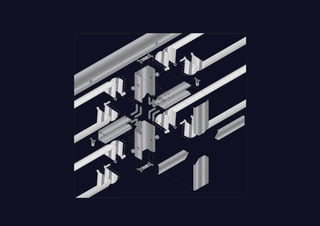

This document provides a summary of a student's master's project on designing buildings with a zero-waste approach. The project involved researching principles of zero-waste building design and applying them to the conceptual design of an industrial building. Key findings included that buildings should be designed so that no waste is produced, materials remain within their material cycles, and components can be reused while maintaining embodied energy. The industrial building design case study demonstrated how to realize these zero-waste principles through design choices like prefabricated elements, demountable connections, and optimizing accessibility for disassembly. The project concluded that zero-waste building design is possible but challenging to implement and require further research to also make it economically feasible.