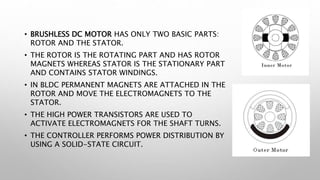

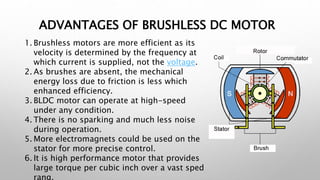

This presentation discusses brushless DC motors. It explains that brushless DC motors do not have brushes, instead using electronics for commutation. This makes them highly efficient over a wide speed range with smooth operation and holding torque when stationary. The presentation describes the basic working principles of brushless DC motors, including their rotor, stator, and electronic control of electromagnets. It discusses how brushless DC motors eliminate the need for commutators through electronic position sensing and switching. Examples of applications are provided, along with advantages like increased efficiency and high performance. Disadvantages include higher cost compared to brushed DC motors and limited high power capabilities.