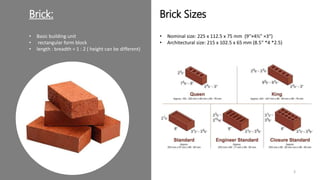

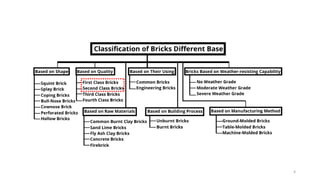

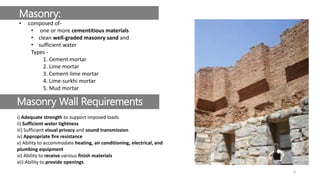

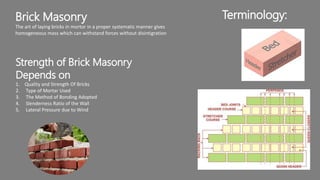

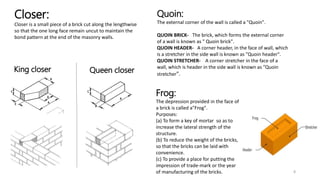

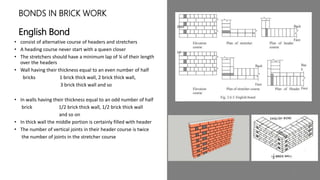

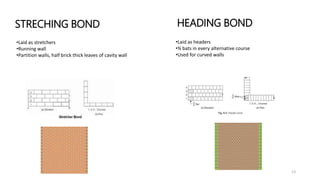

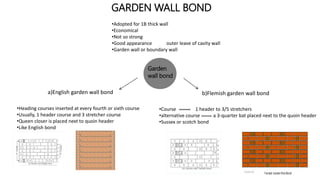

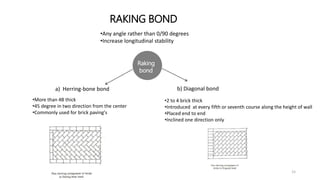

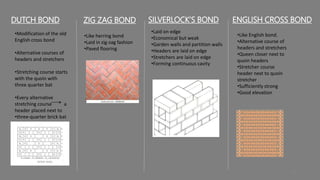

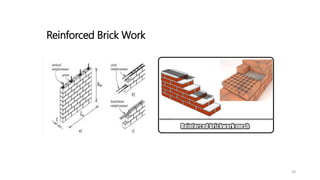

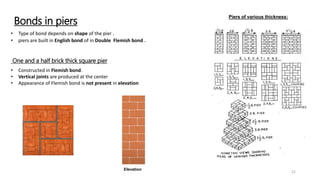

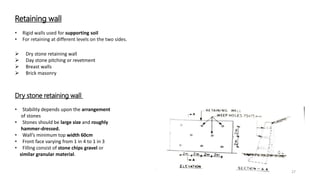

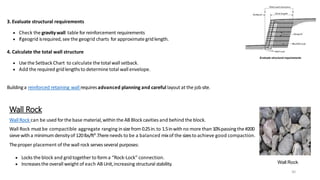

The document provides a comprehensive overview of brick masonry, detailing definitions, classifications, materials, bonding techniques, and the tools used in the craft. It covers the strength factors affecting brick masonry, design principles for masonry walls, and the structural requirements for retaining walls. Key terminologies, types of bonds, and common defects in masonry are also discussed, emphasizing the importance of proper techniques for stability and durability.