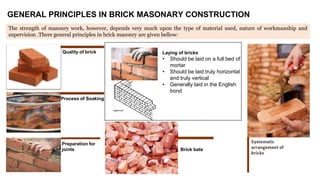

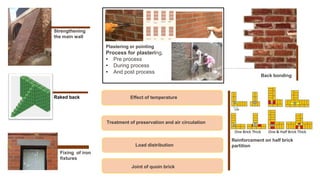

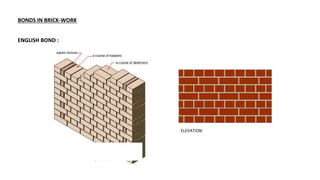

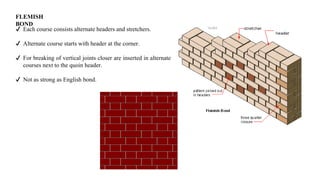

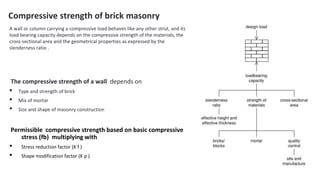

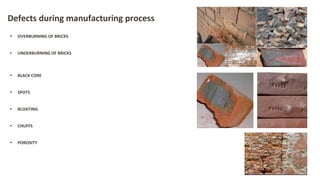

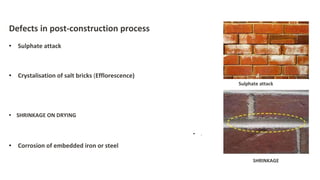

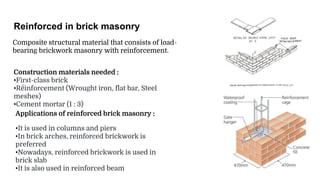

The document provides a comprehensive overview of brick masonry, detailing its definition, types of bricks, construction principles, and various bonding techniques. It covers the strength of brick masonry, permissible compressive stress, and common defects, emphasizing the importance of quality workmanship. Additionally, it discusses reinforced brickwork advantages, types of bonds, and considerations for constructing retaining walls and other masonry structures.

![NOMINAL THICKNESS OF WALL

Estimated wall thickness to evaluate the quantity of brick work

Fictitious dimension

The nominal thickness of one brick wall,

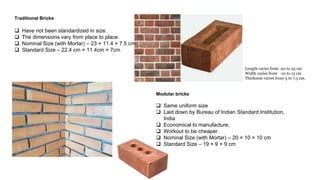

Traditional brick

• Taken as 23 cm [allowance mortar joint =12mm]

• Actual thickness varies from 21.8cm to 22.4cm

Modular brick

• Taken as 20 cm [allowance mortar joint =10mm]

• Actual thickness is 19cm](https://image.slidesharecdn.com/brickmasonry-group-3-220403161457/85/Brick-Masonry-5-320.jpg)