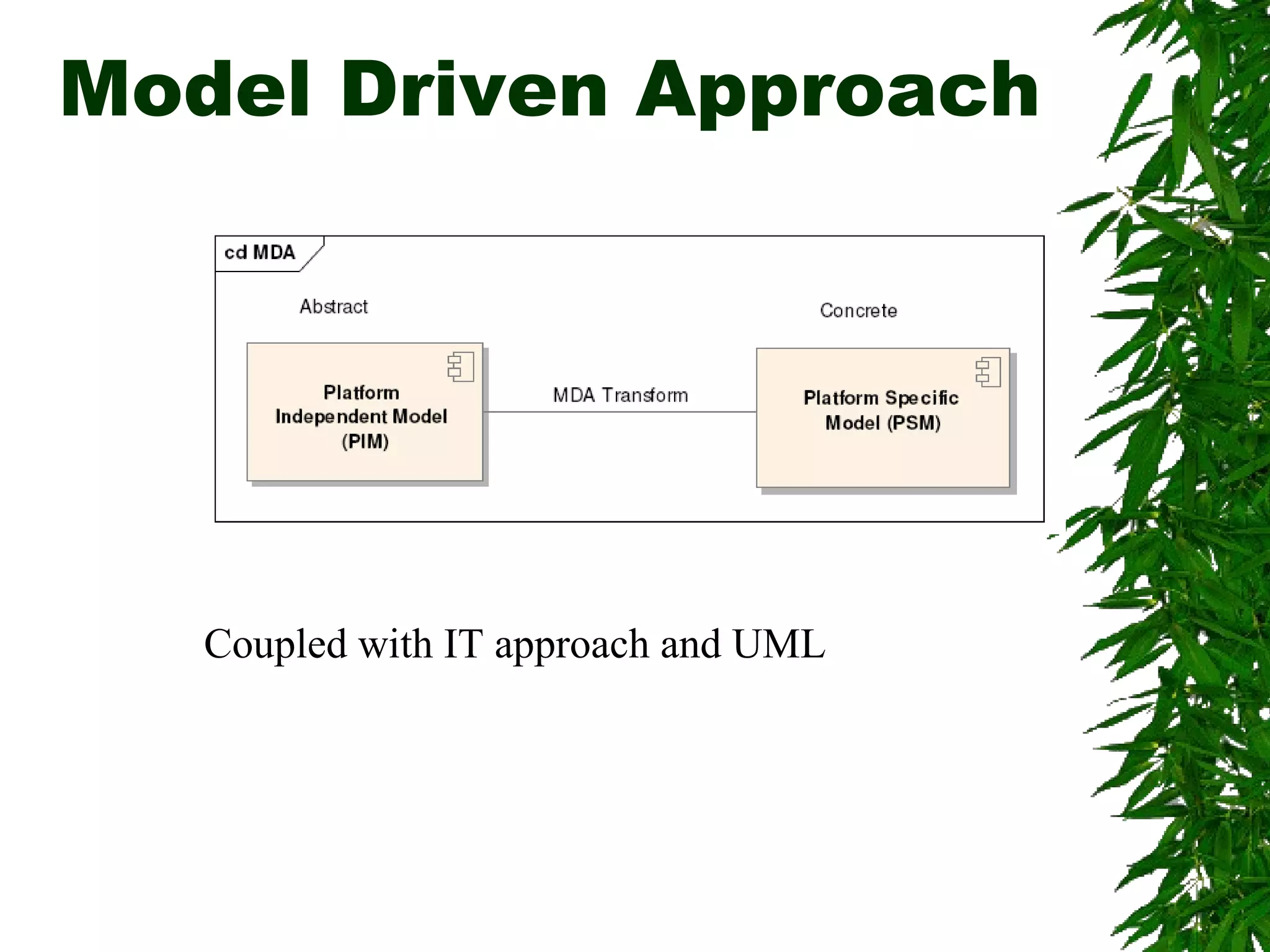

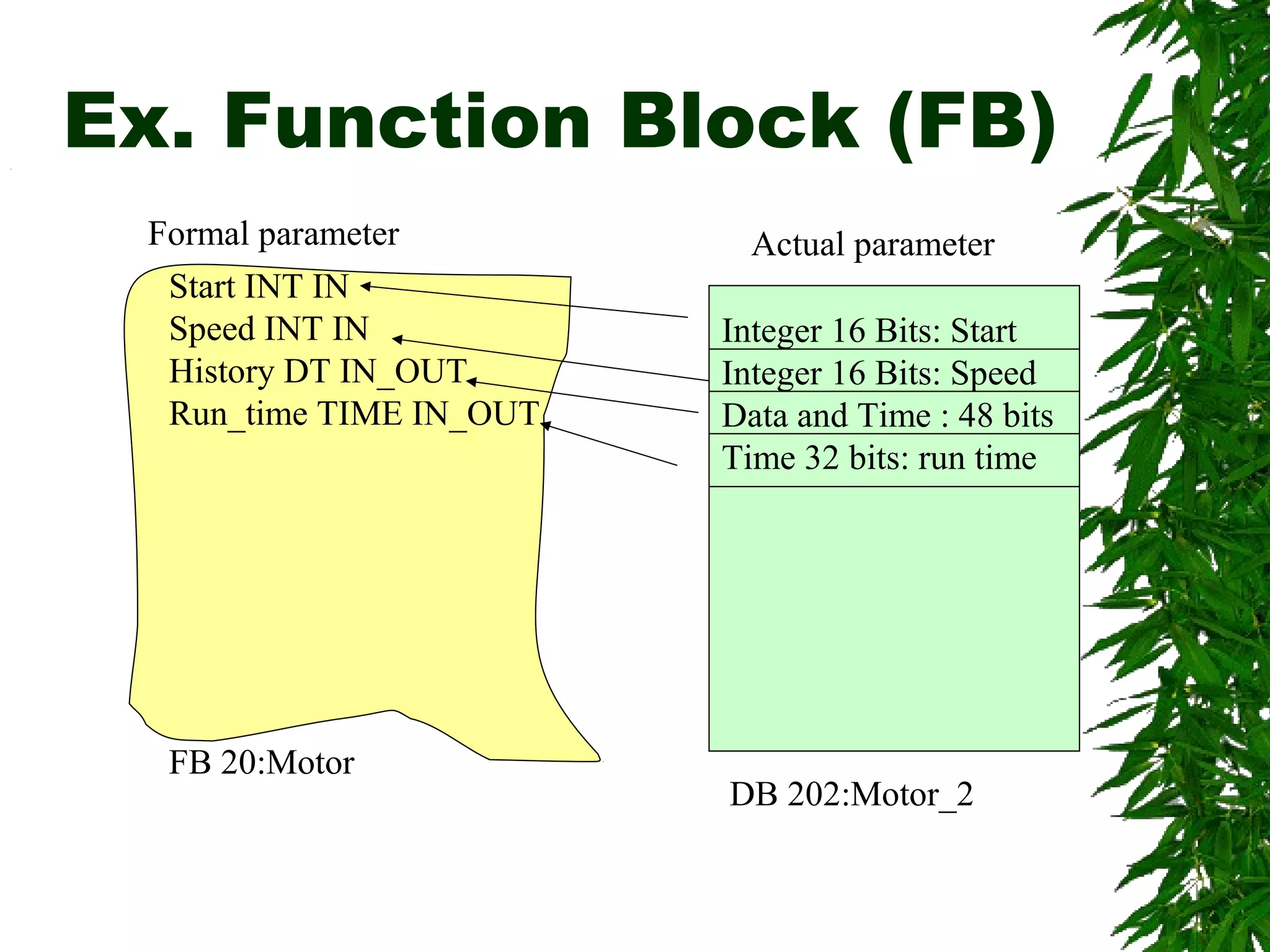

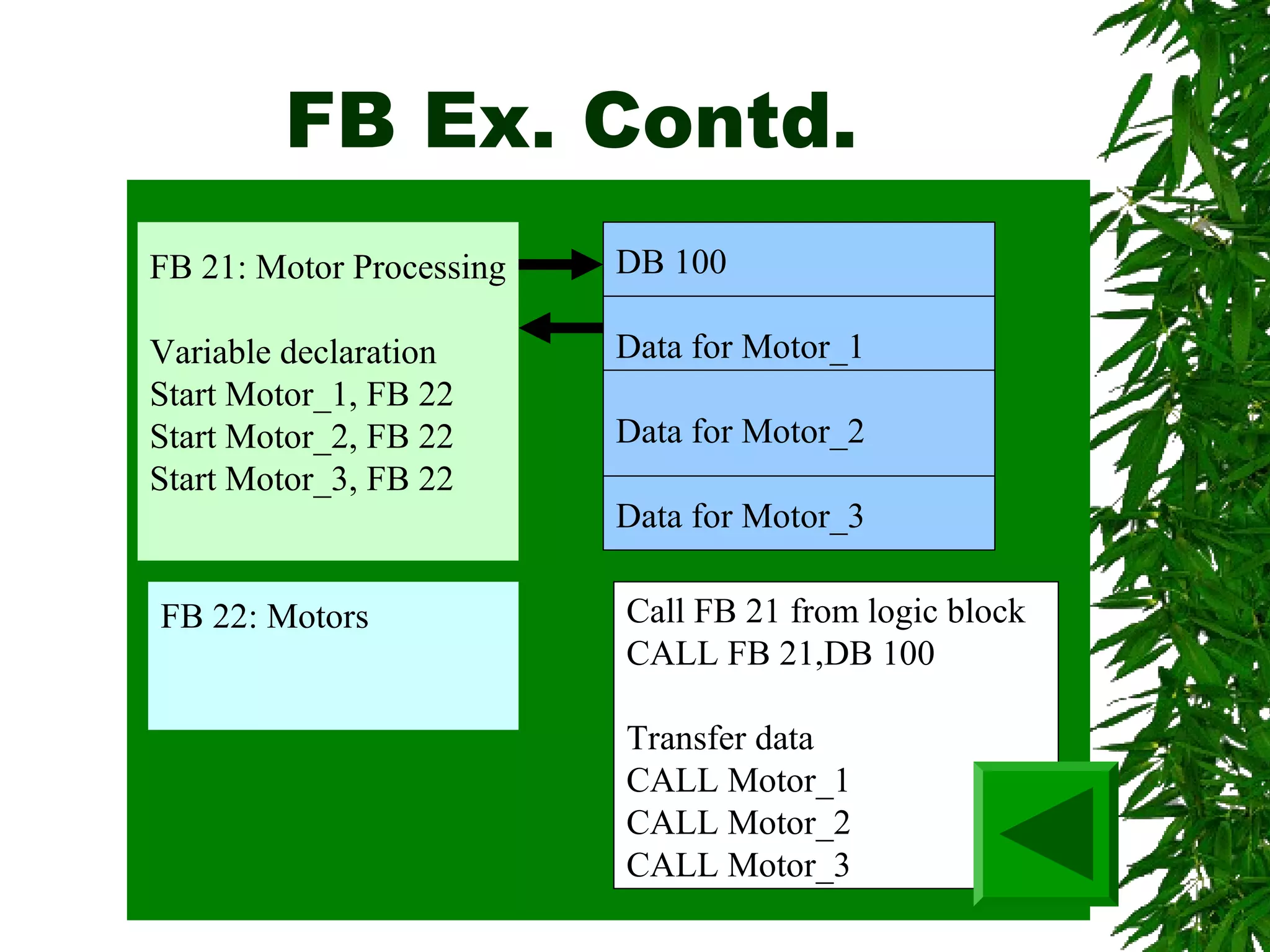

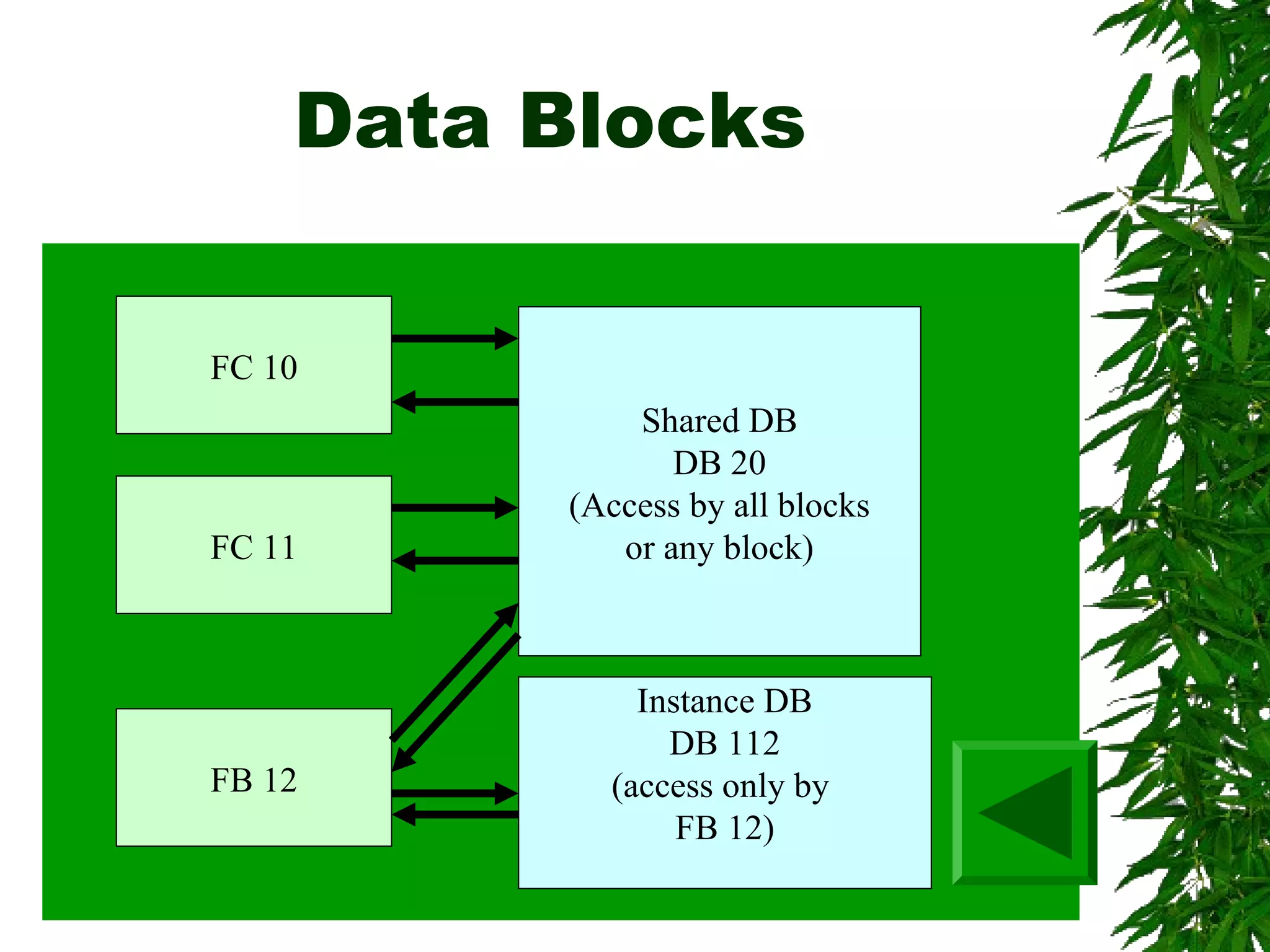

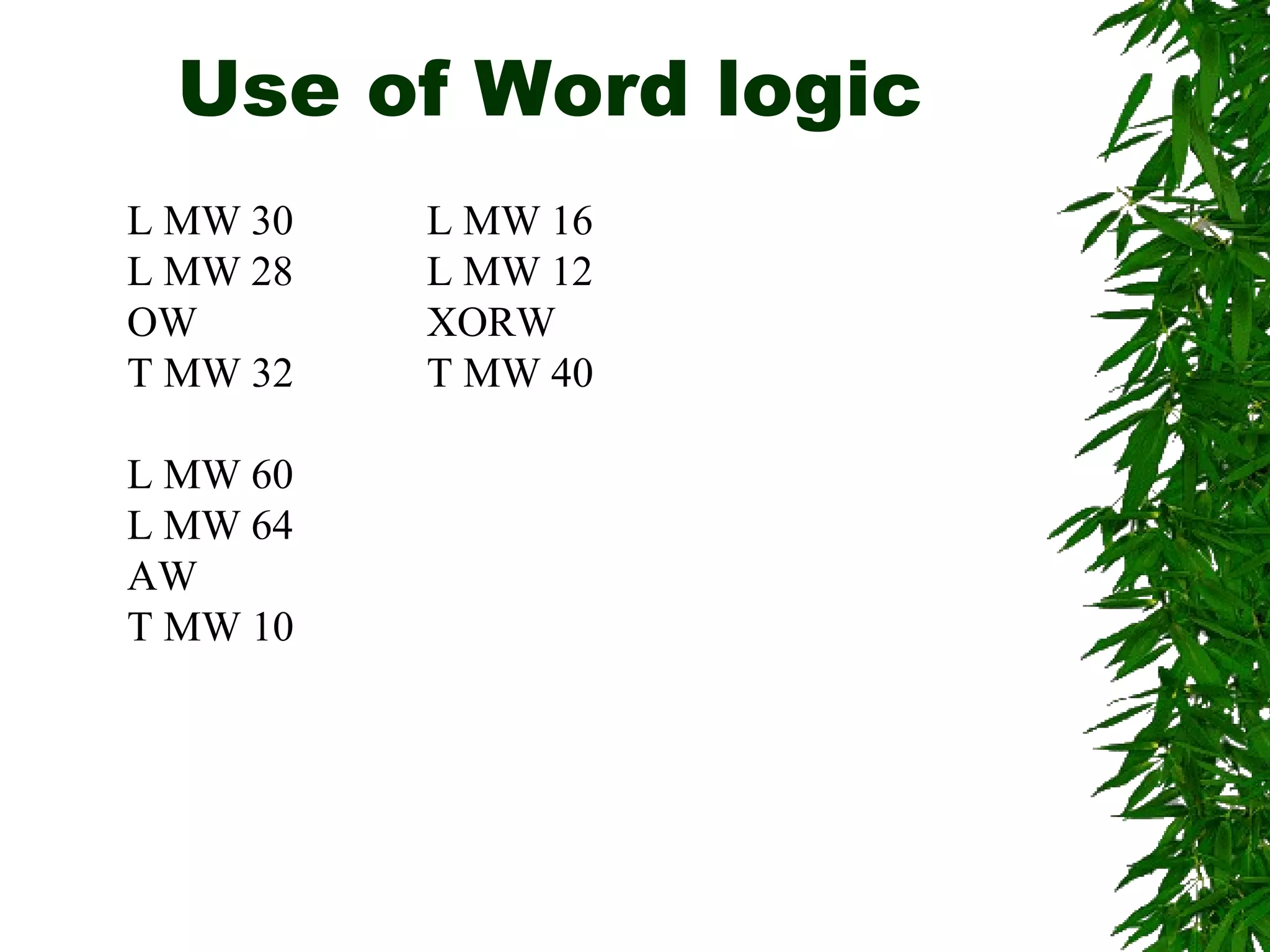

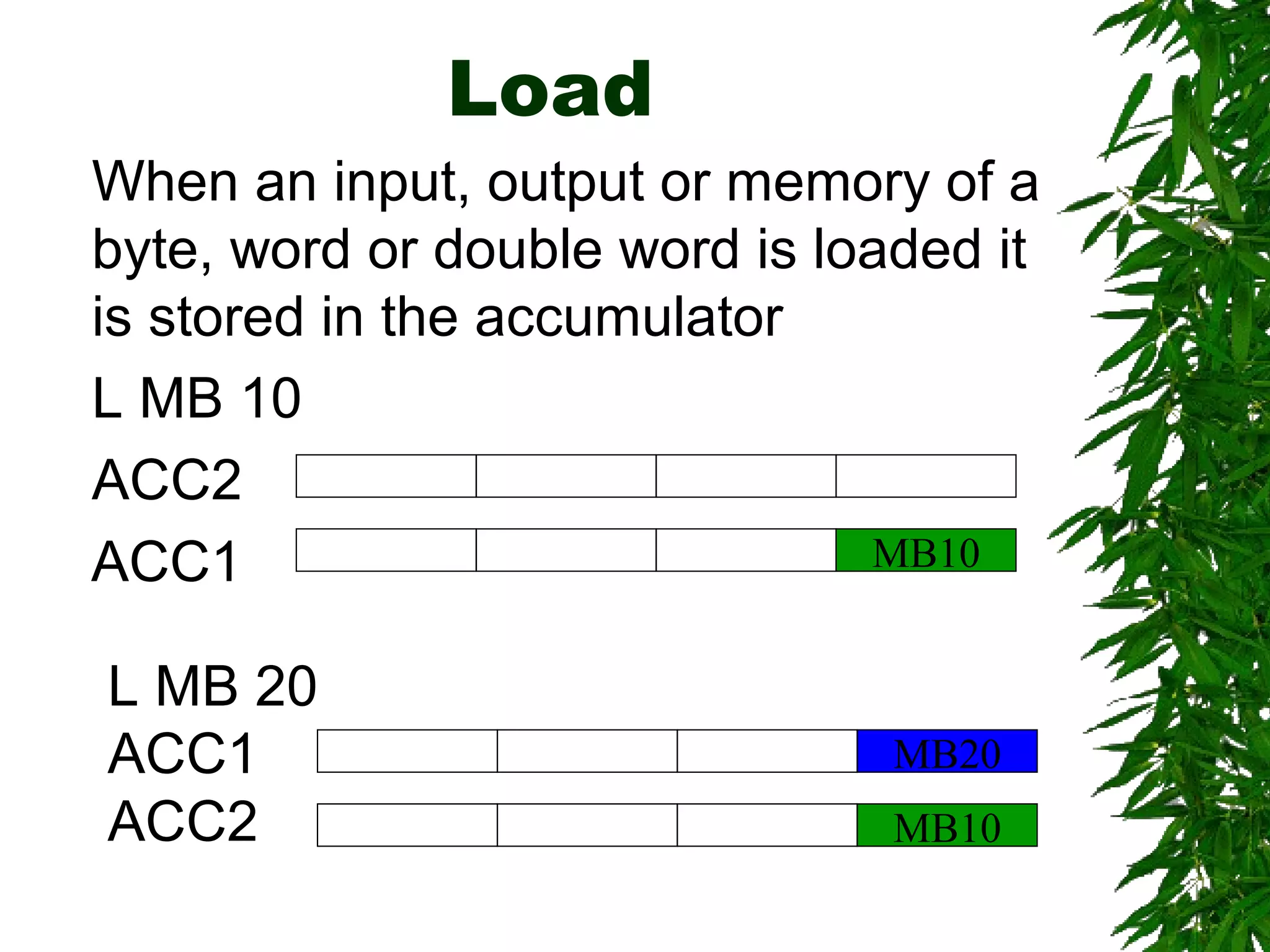

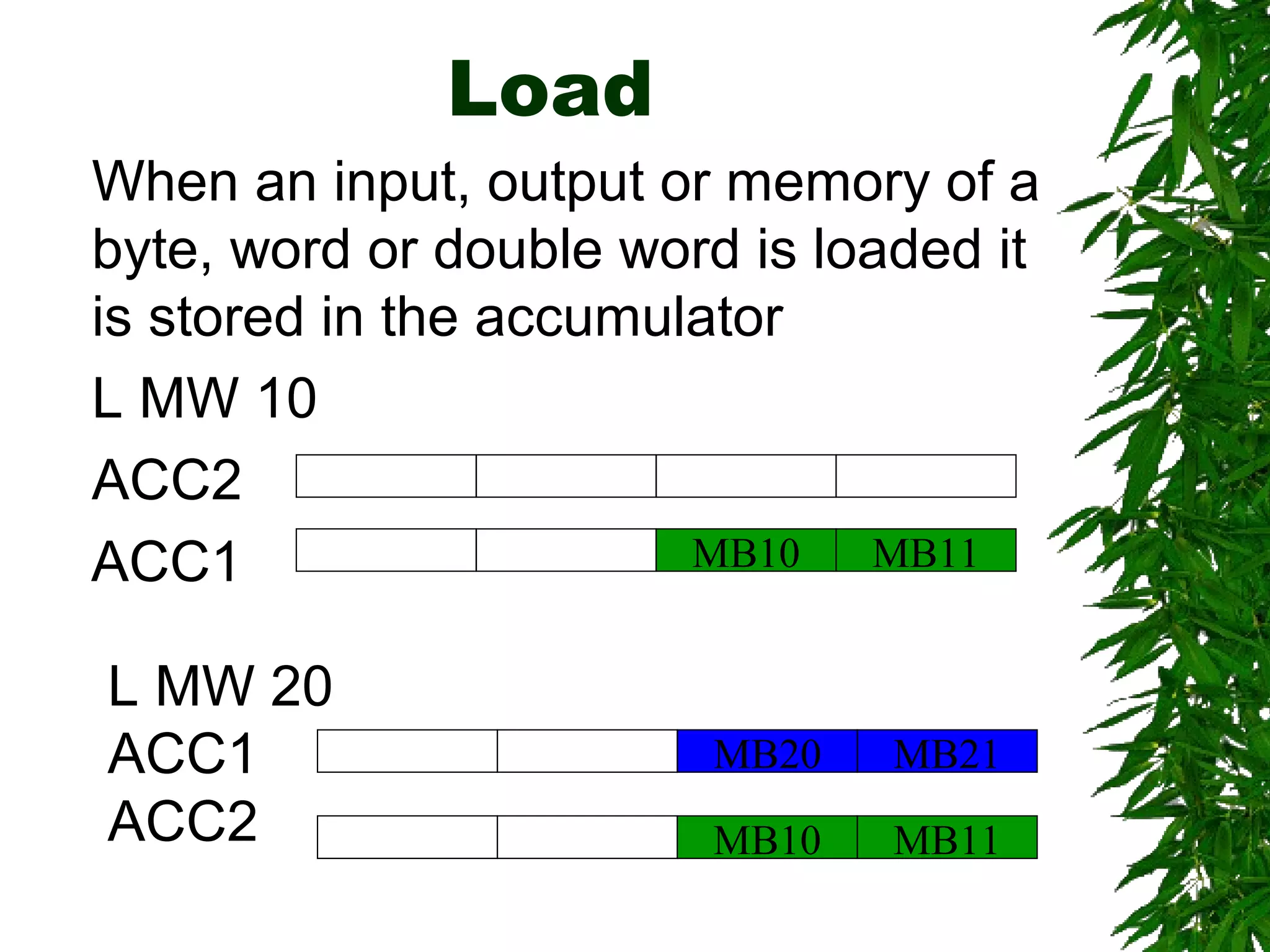

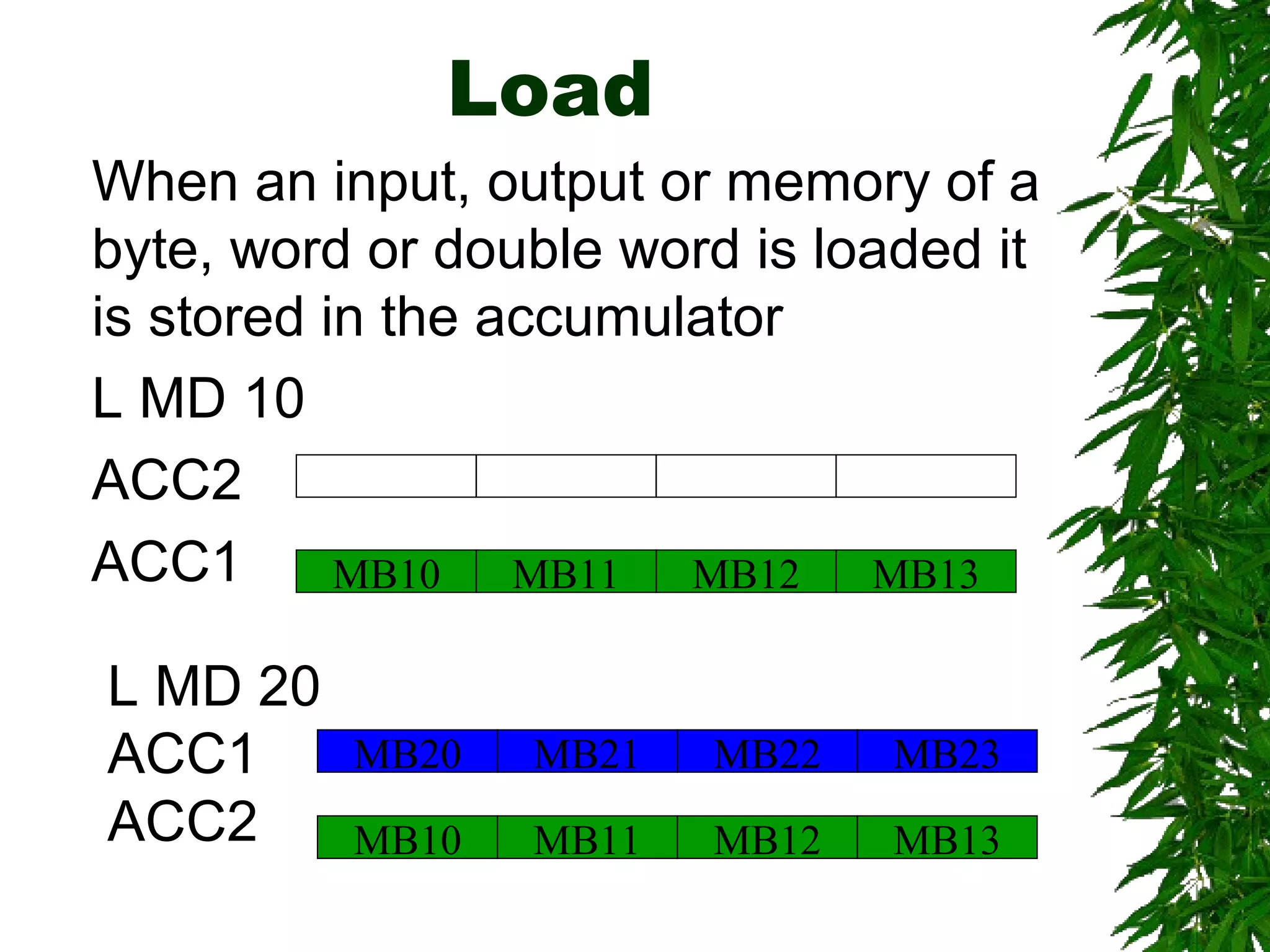

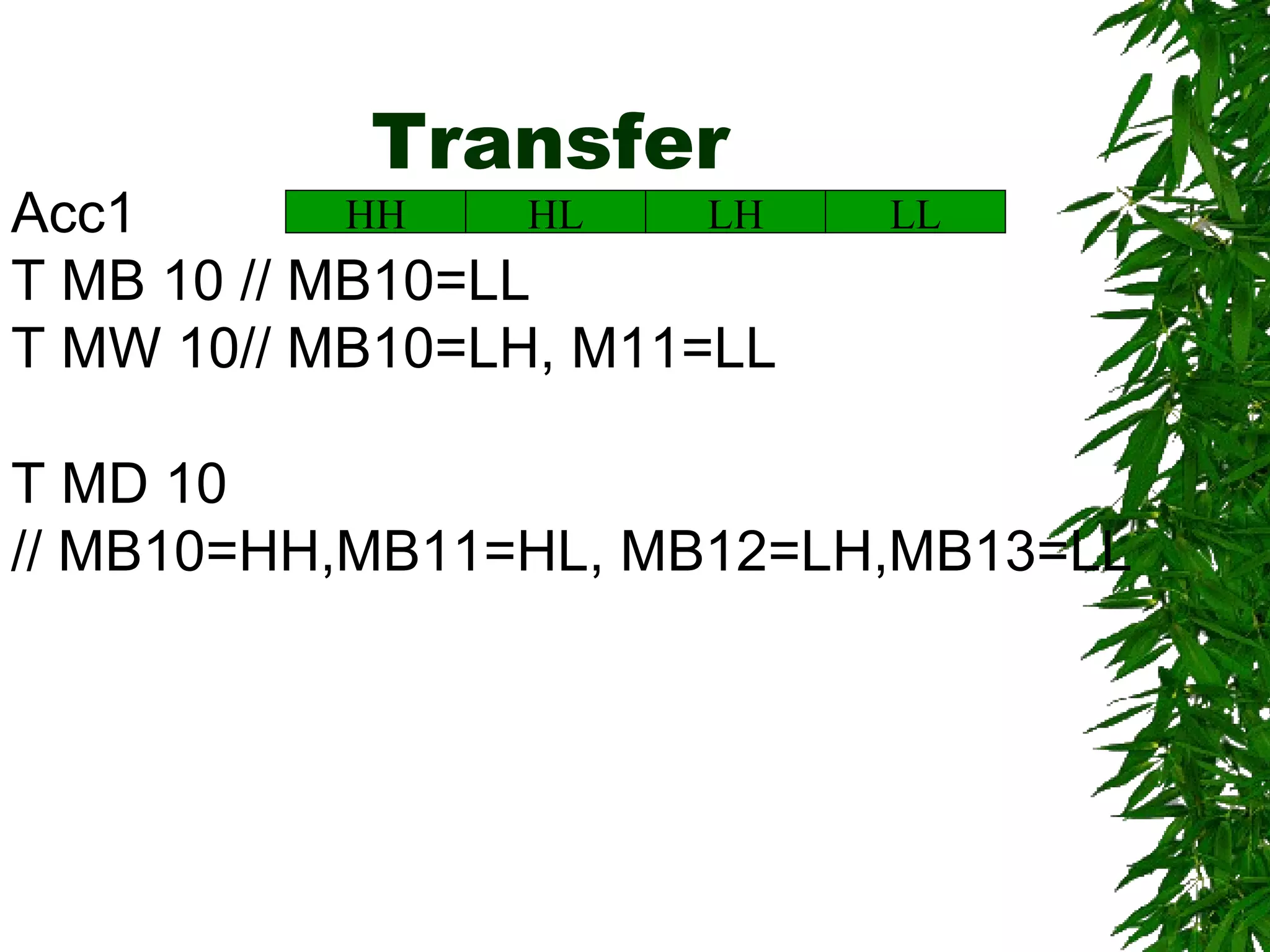

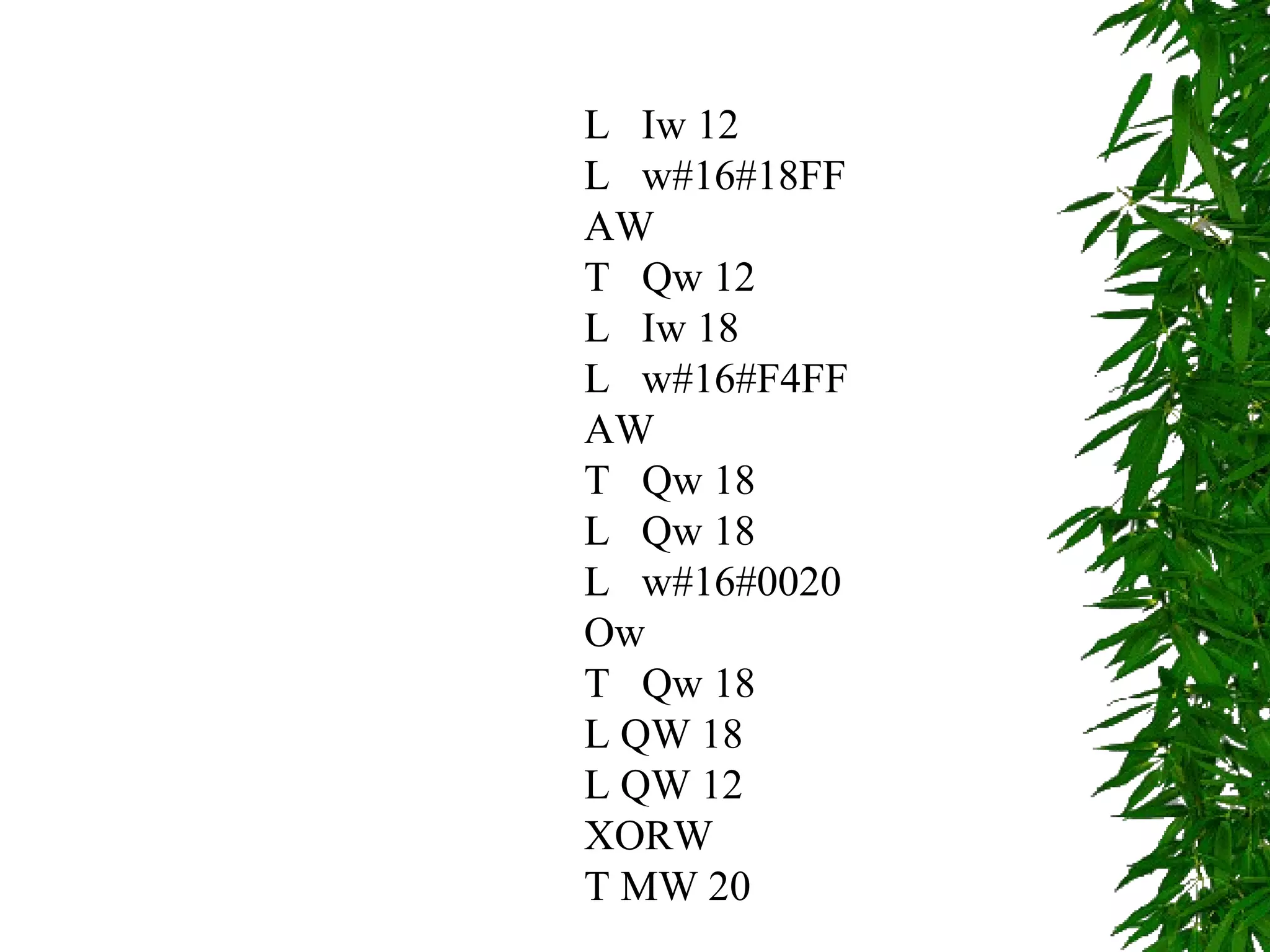

This document discusses designing and programming advanced programmable logic controllers (PLCs). It covers topics like modeling driven and component based approaches to automation, planning automation systems by identifying requirements and selecting components, and programming PLCs using blocks, functions, data blocks, and word logic instructions. The document provides examples of function blocks and how to use word logic like load, transfer, arithmetic, and bit logic operations in PLC programs.