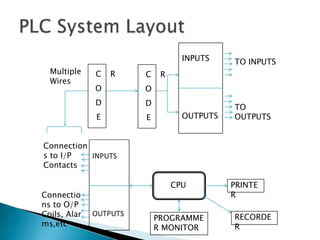

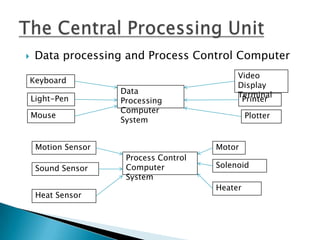

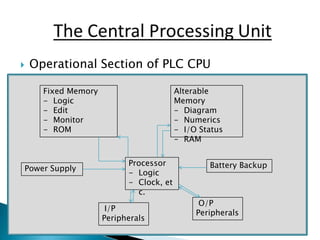

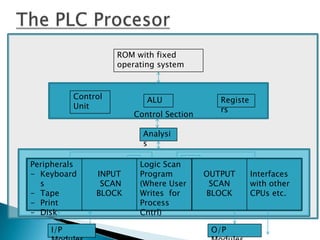

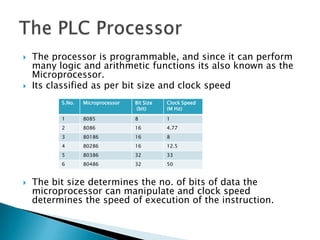

A PLC is a digitally operated electronic device that uses programmable memory to implement specific functions. It has several advantages including flexibility, easy error correction, cost effectiveness, and reliable operation. The PLC processor and memory are located in the CPU. The CPU contains fixed and alterable memory. The control unit manages input/output scanning and logic processing based on the user-written program. PLCs are commonly used in industrial manufacturing applications for process control.