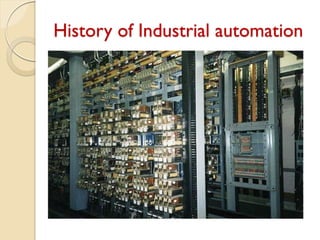

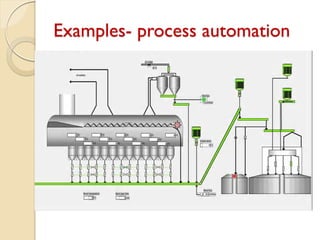

Industrial automation involves using programmable logic controllers and connecting them to a central computer to provide stability, accuracy and eliminate harmful transitions in production processes. A PLC controller is at the central part of an automated system, continuously monitoring inputs and executing actions based on the programmed logic. Previously, relay-based control systems with wired boards were used, but they had disadvantages like being difficult to change and find errors. The programmable logic controller was developed in 1968 to replace these wired systems and provide an easily maintained and programmed solution using relay ladder logic. Automation brings benefits like faster production, safer operations in hazardous environments, and replacing repetitive physical work.