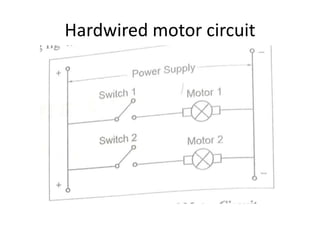

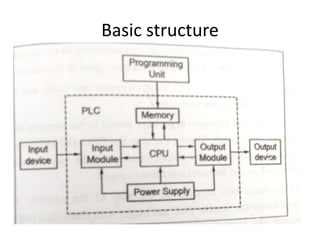

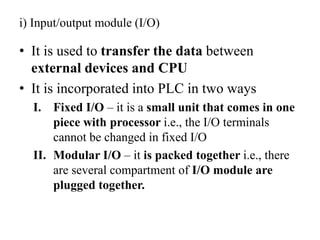

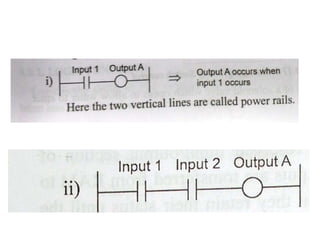

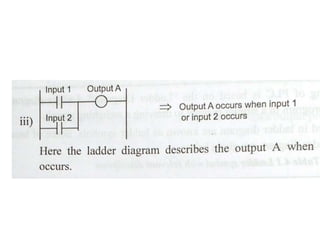

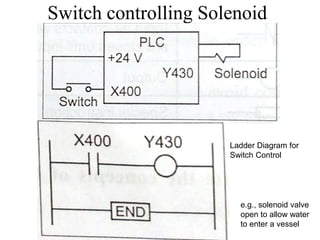

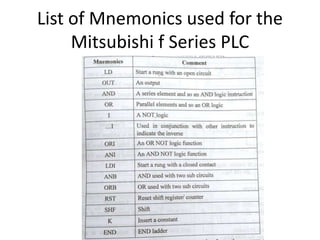

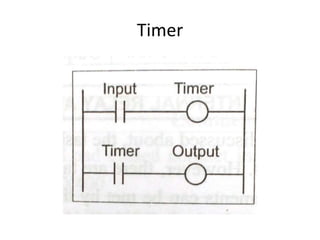

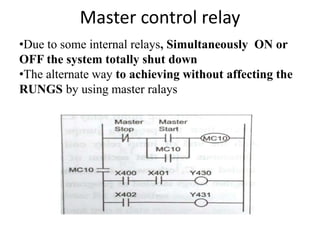

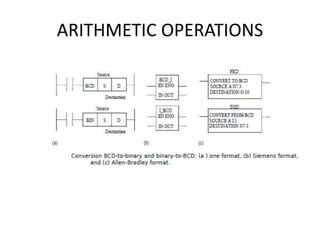

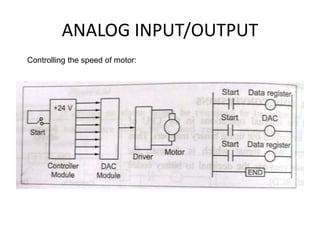

This document provides an overview of programmable logic controllers (PLCs). It describes the basic structure of a PLC including input/output modules, a central processing unit, memory, and a programming unit. The document outlines how PLCs are used to automate industrial processes through input/output processing and programming using ladder logic and mnemonics. Additional features of PLCs like timers, counters, internal relays, and data handling are also summarized. The document concludes with factors to consider when selecting a PLC for an automation application.