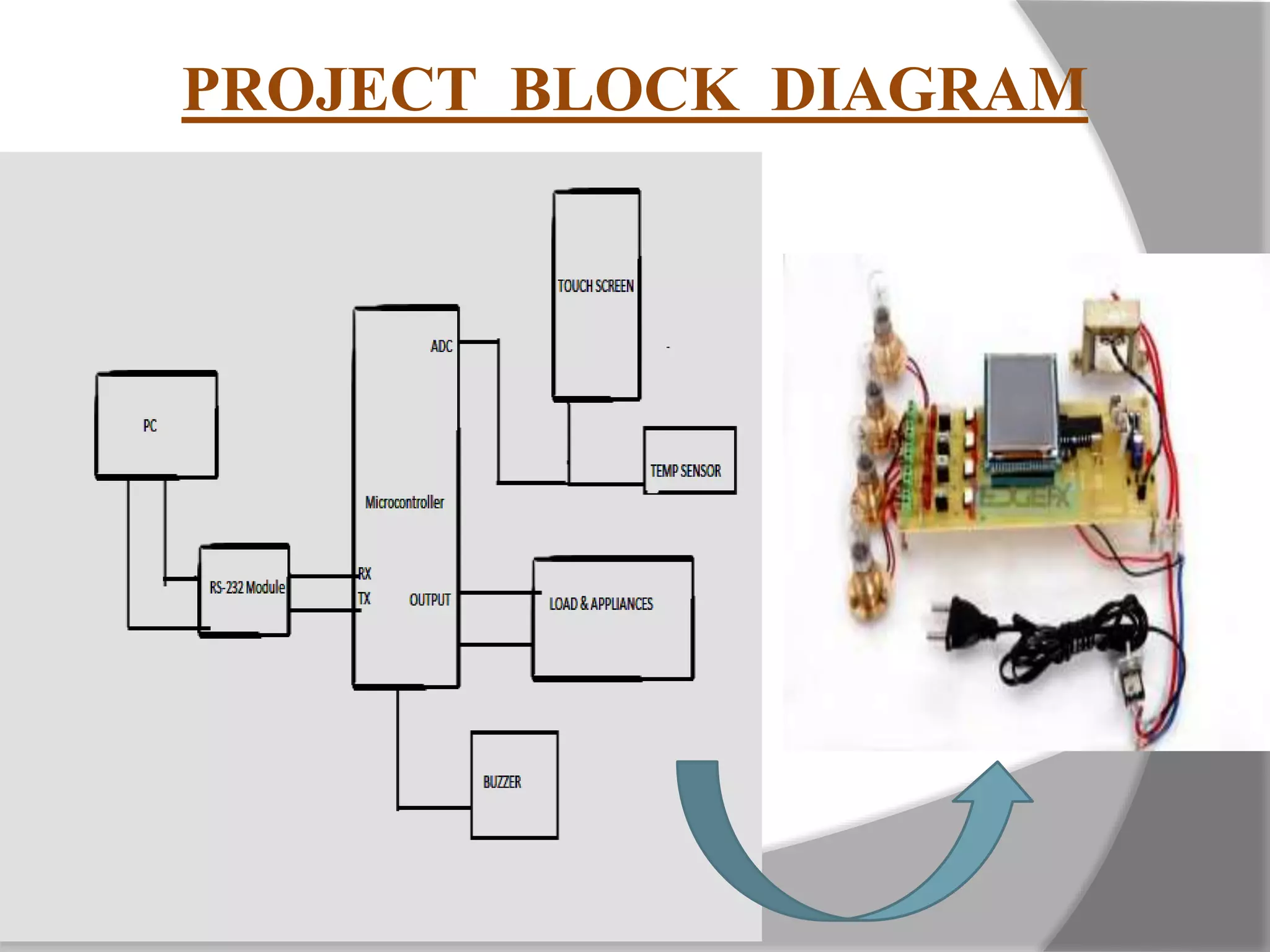

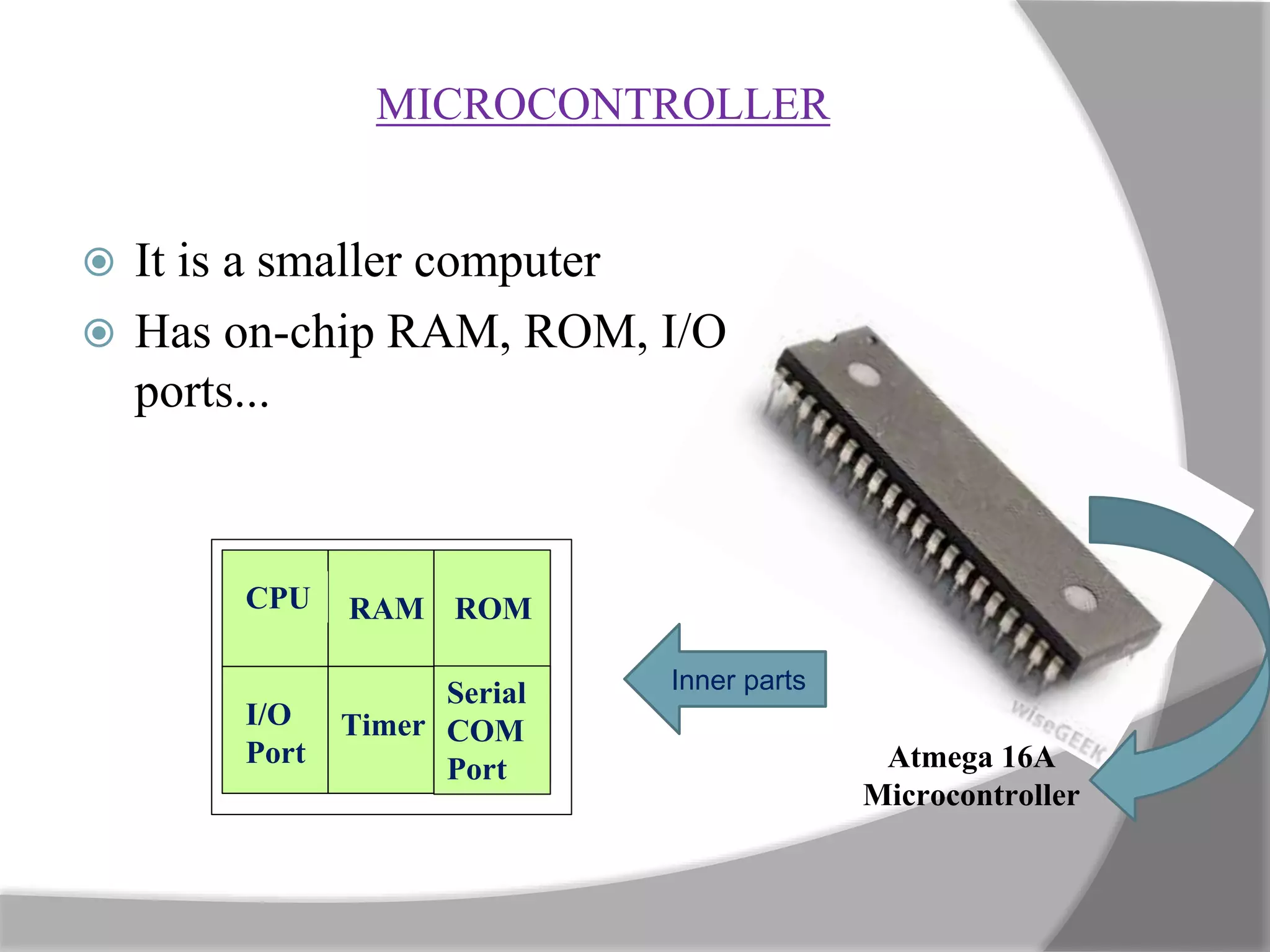

This document describes an industrial automation project that uses a touchscreen and PC to control loads, appliances, and other necessary equipment. The PC interfaces with a microcontroller via RS-232 to control appliances and motor speed. The touchscreen is used to control gates. The project aims to provide remote monitoring and control of industrial processes through a PC and touchscreen interface for improved efficiency.