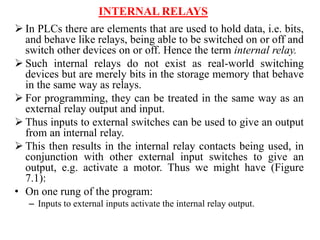

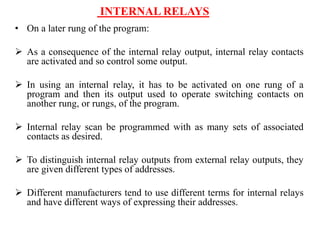

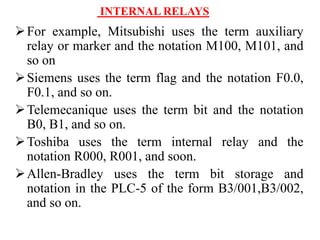

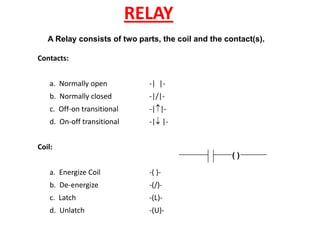

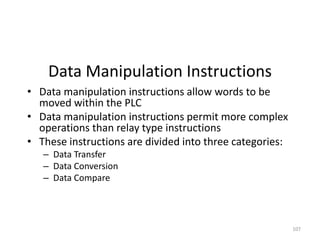

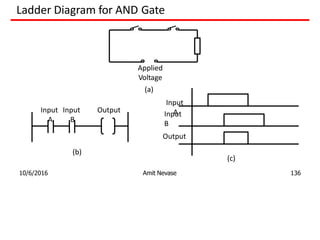

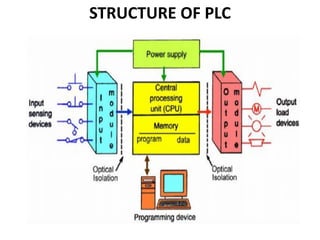

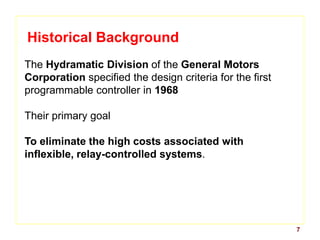

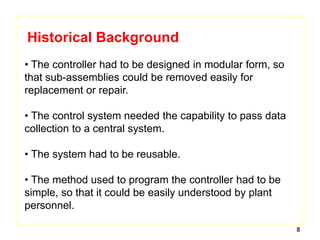

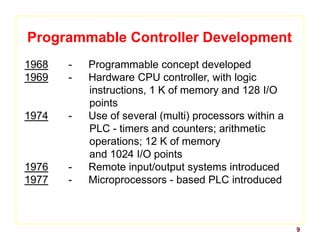

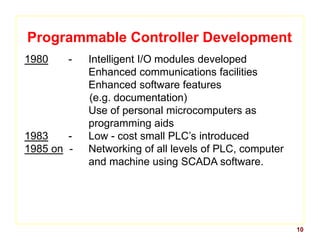

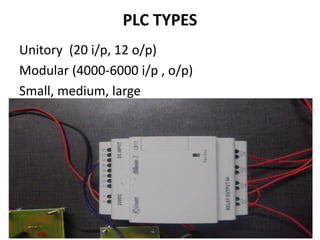

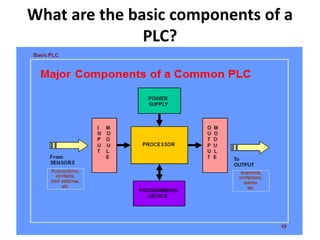

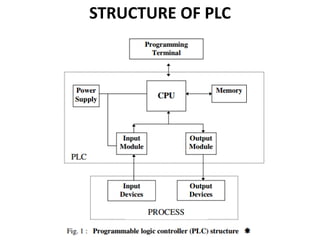

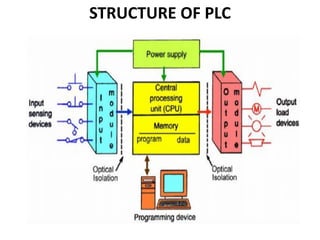

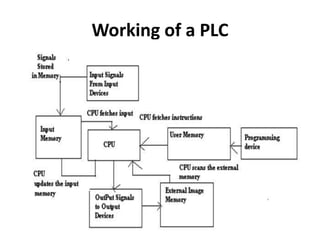

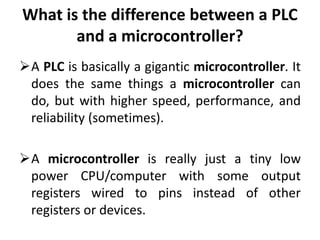

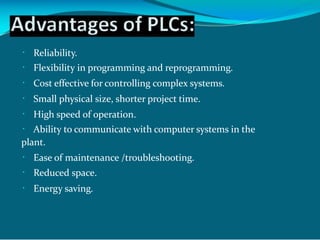

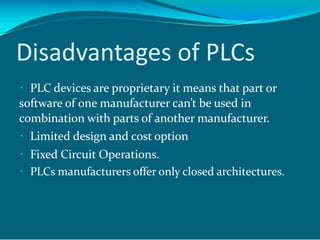

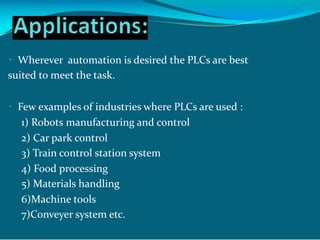

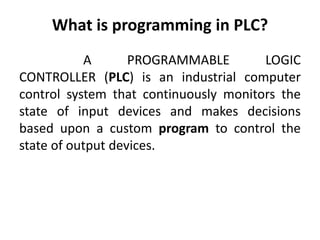

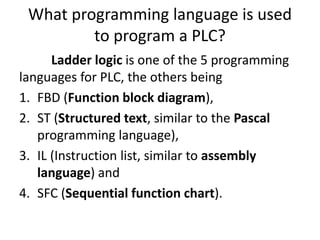

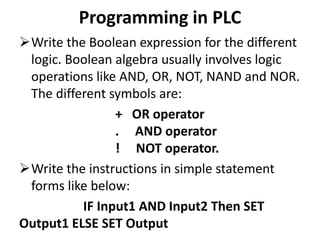

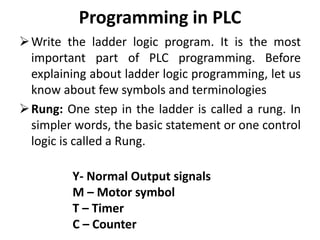

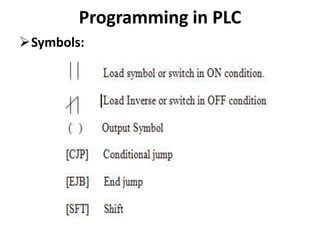

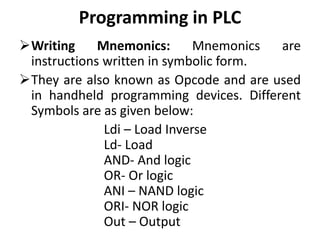

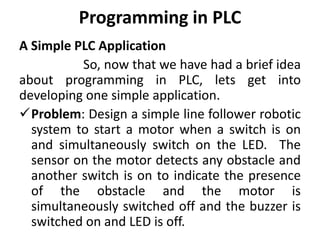

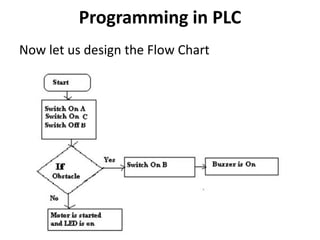

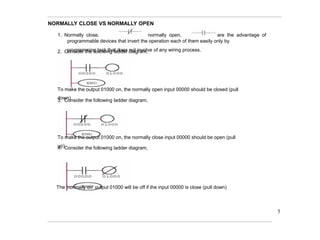

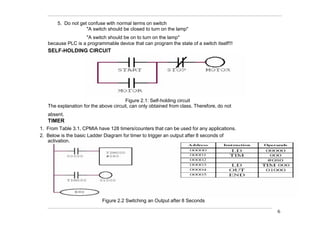

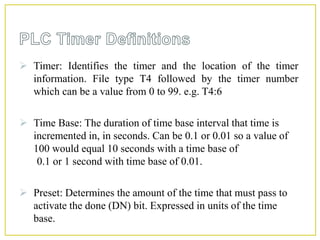

This document provides an introduction to Programmable Logic Controllers (PLCs). It discusses the history and evolution of control systems from humans to relays to PLCs. The key components of a PLC including the input/output modules, central processing unit, memory, and programming terminal are described. Programming methods for PLCs such as ladder logic, Boolean expressions, and mnemonics are also introduced. Examples of using timers, counters, and internal relays in PLC programs are provided.

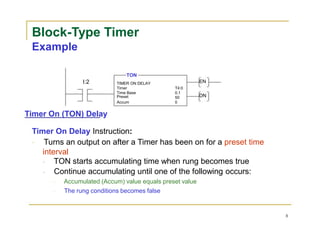

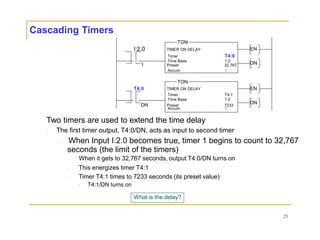

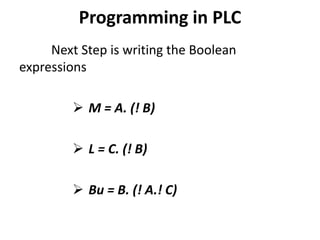

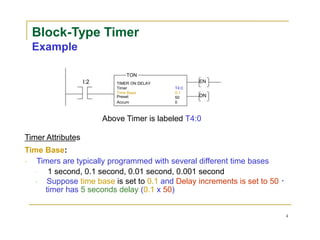

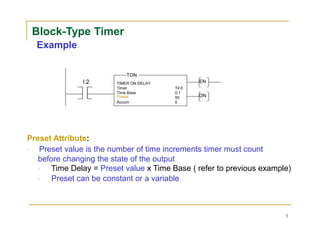

![Block-Type Timer

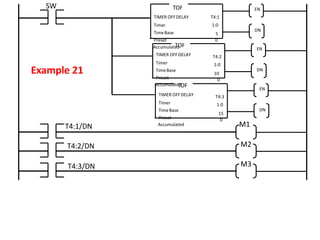

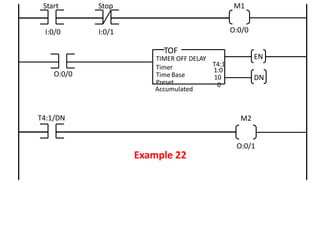

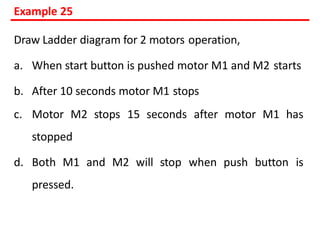

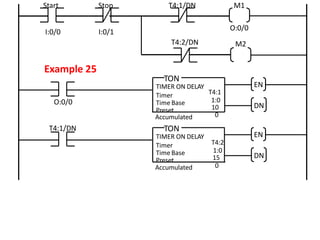

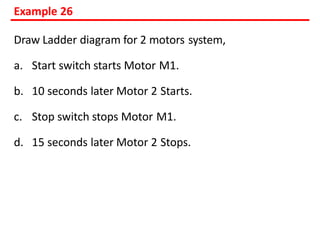

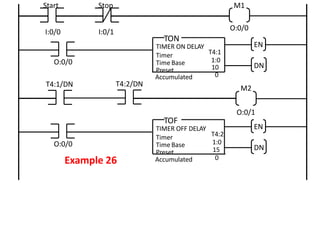

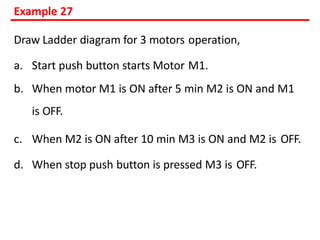

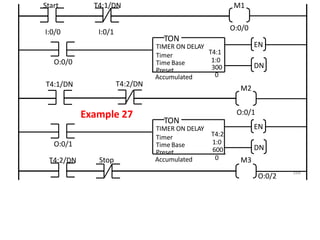

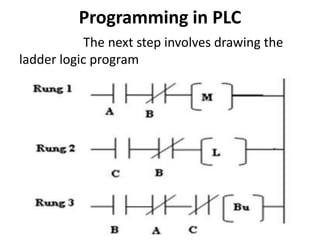

Example

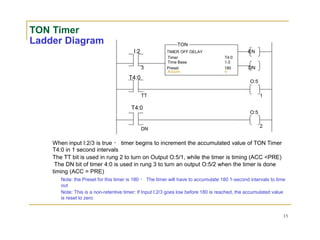

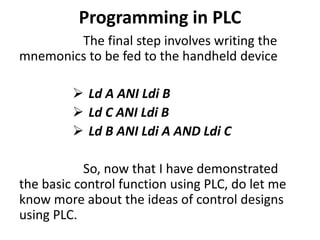

TON

I:2 TIMER ON DELAY EN

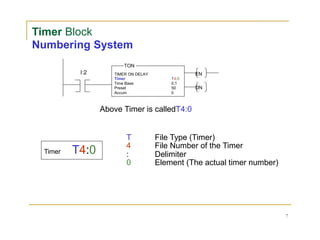

Timer T4:0

Time Base 0.1

Preset 50 DN

Accum 0

Accum Attribute:

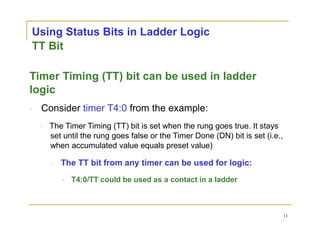

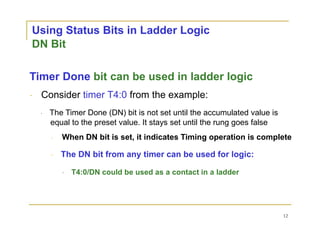

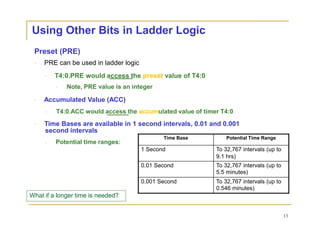

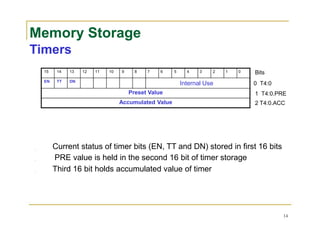

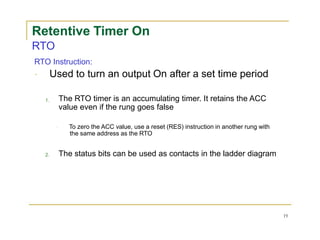

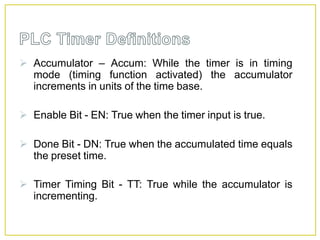

[Rockwell] Timers have one input. When the input transits from low

to high, the timer will begin timing (Accum value)

Timers that do not lose their accumulated time when the enable input line

transitions to low again are known as Retentive Timers

Retentive Timers continue to maintain accumulated time and increment

the time when the input line goes to high again

Non-retentive Timers lose the accumulated time whenever the enable

input transitions to low

The accumulated time resets to zero

6](https://image.slidesharecdn.com/unit4-211006040644/85/Introduction-to-PLC-70-320.jpg)