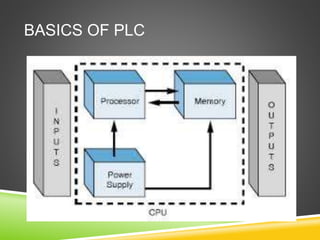

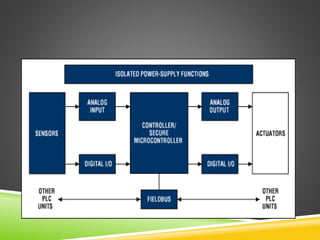

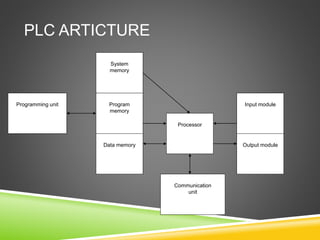

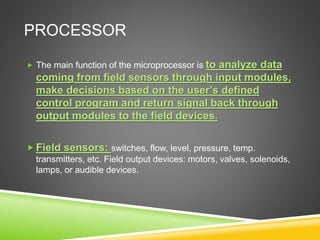

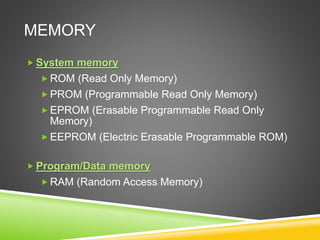

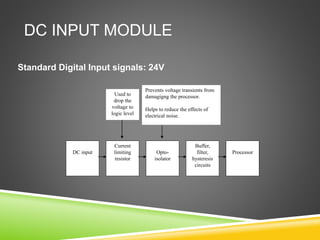

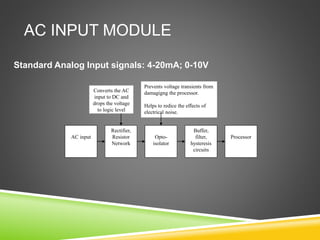

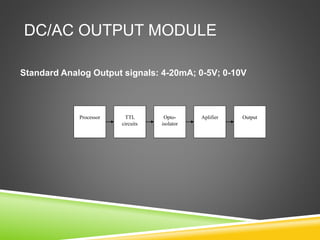

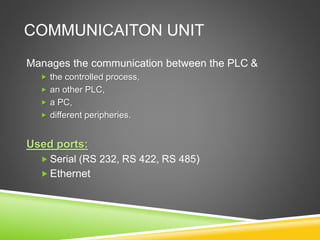

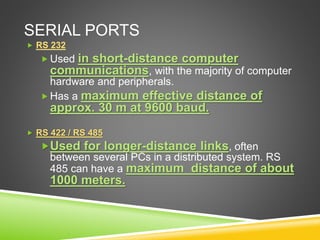

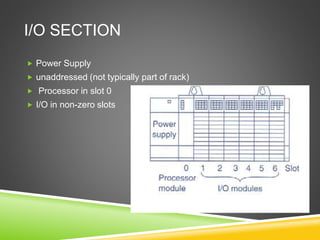

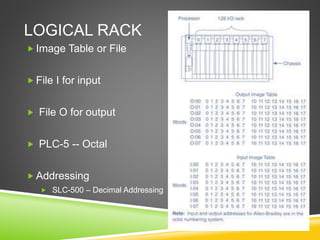

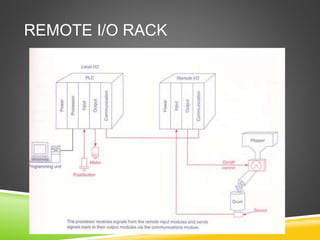

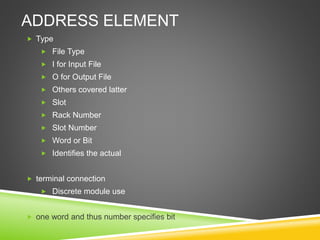

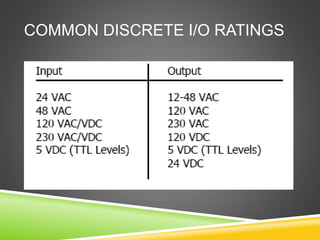

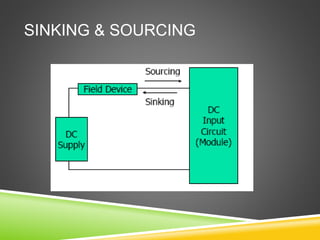

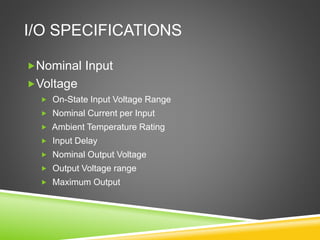

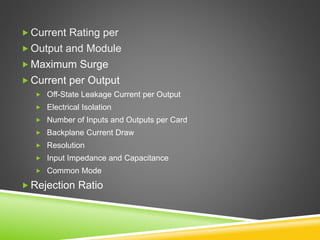

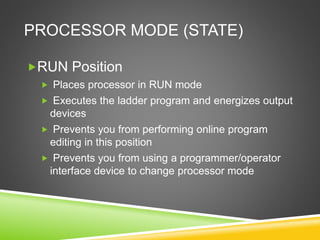

The document provides a comprehensive overview of Programmable Logic Controllers (PLCs), including their architecture, hardware components, types of memory, and input/output modules. It highlights the evolution of PLCs from relay controllers to semiconductor logic controllers, emphasizing advantages like adaptability and minimal maintenance. It also discusses communication units and the advantages and disadvantages of PLC systems in industrial applications.