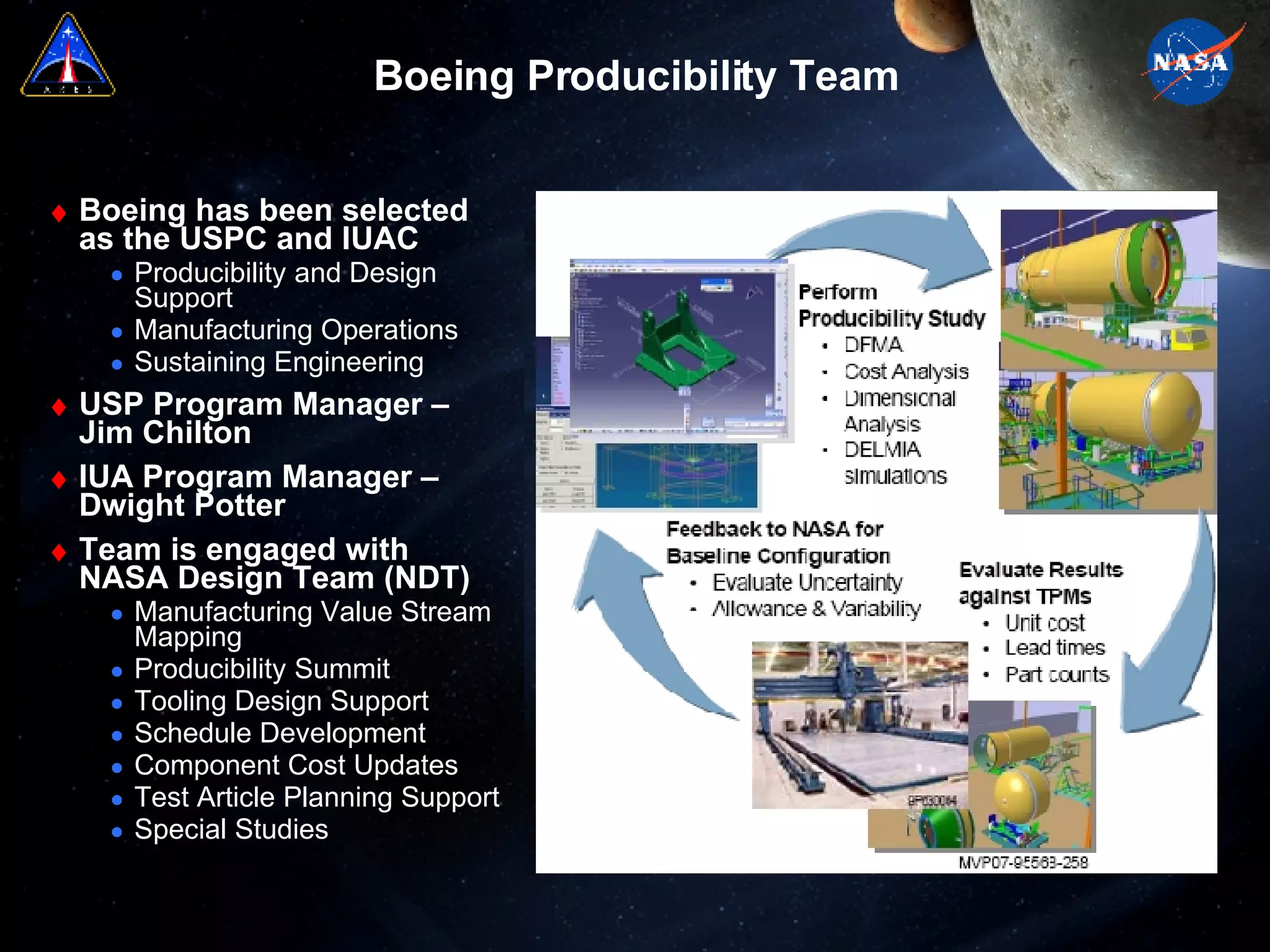

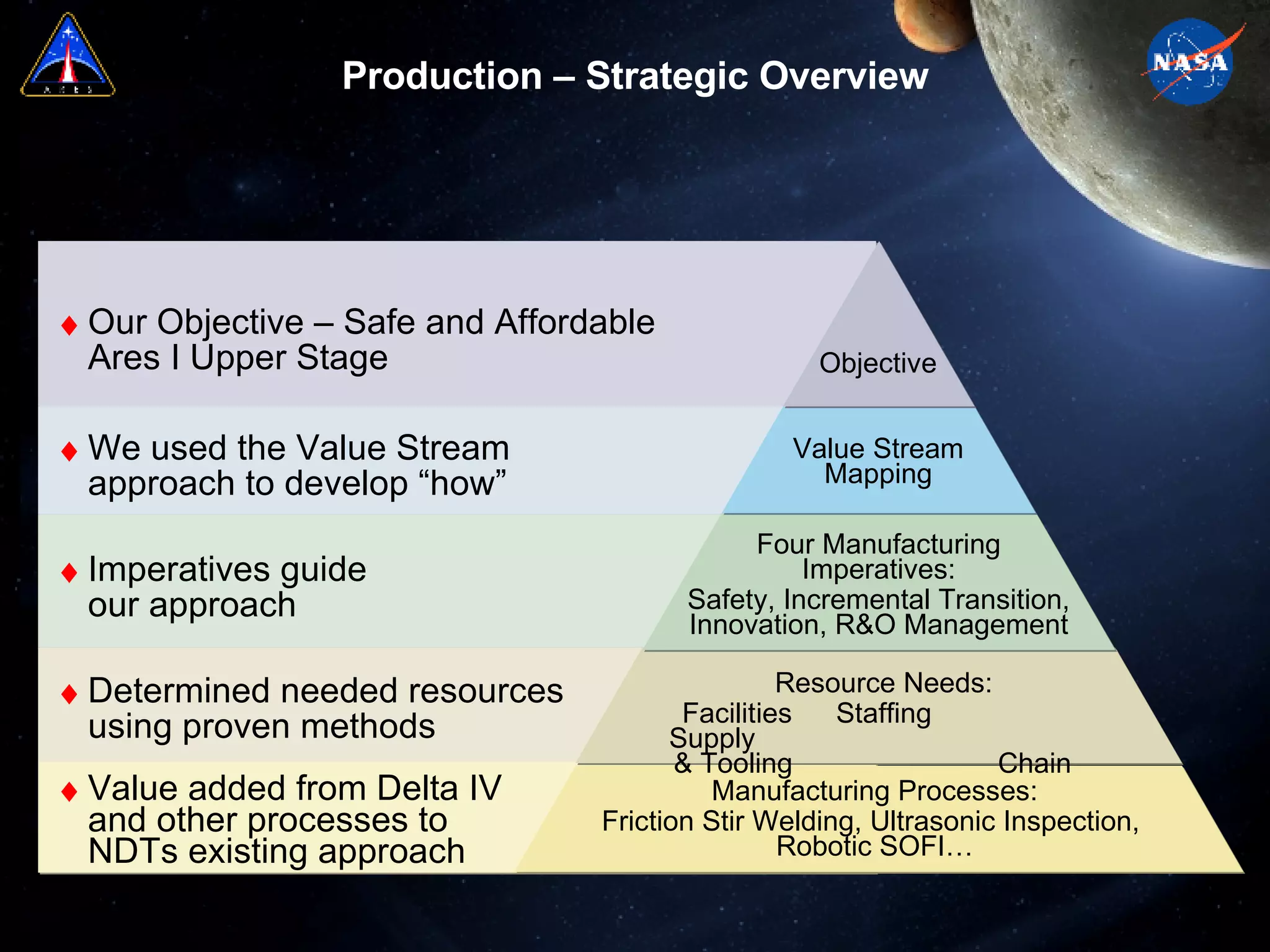

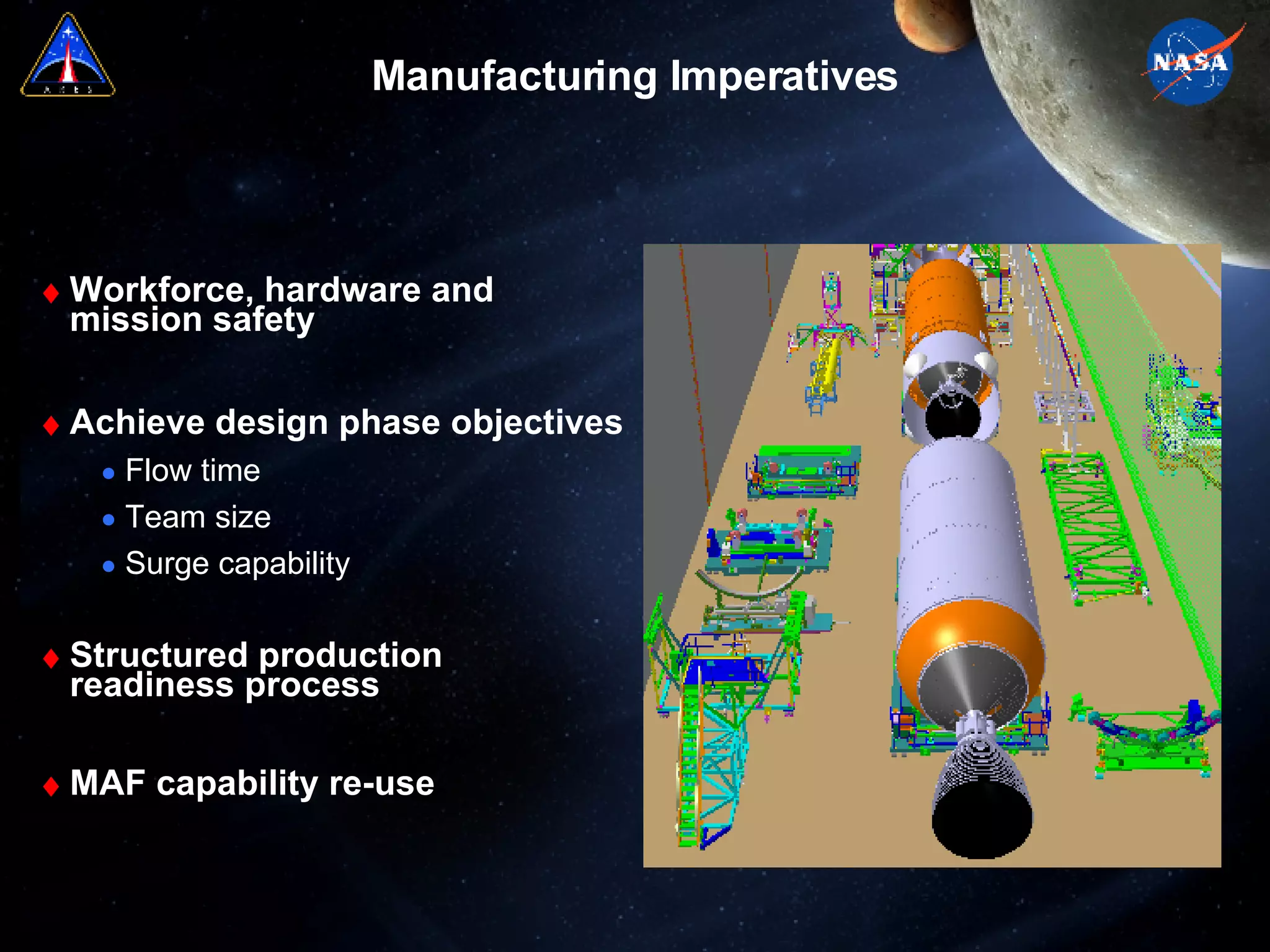

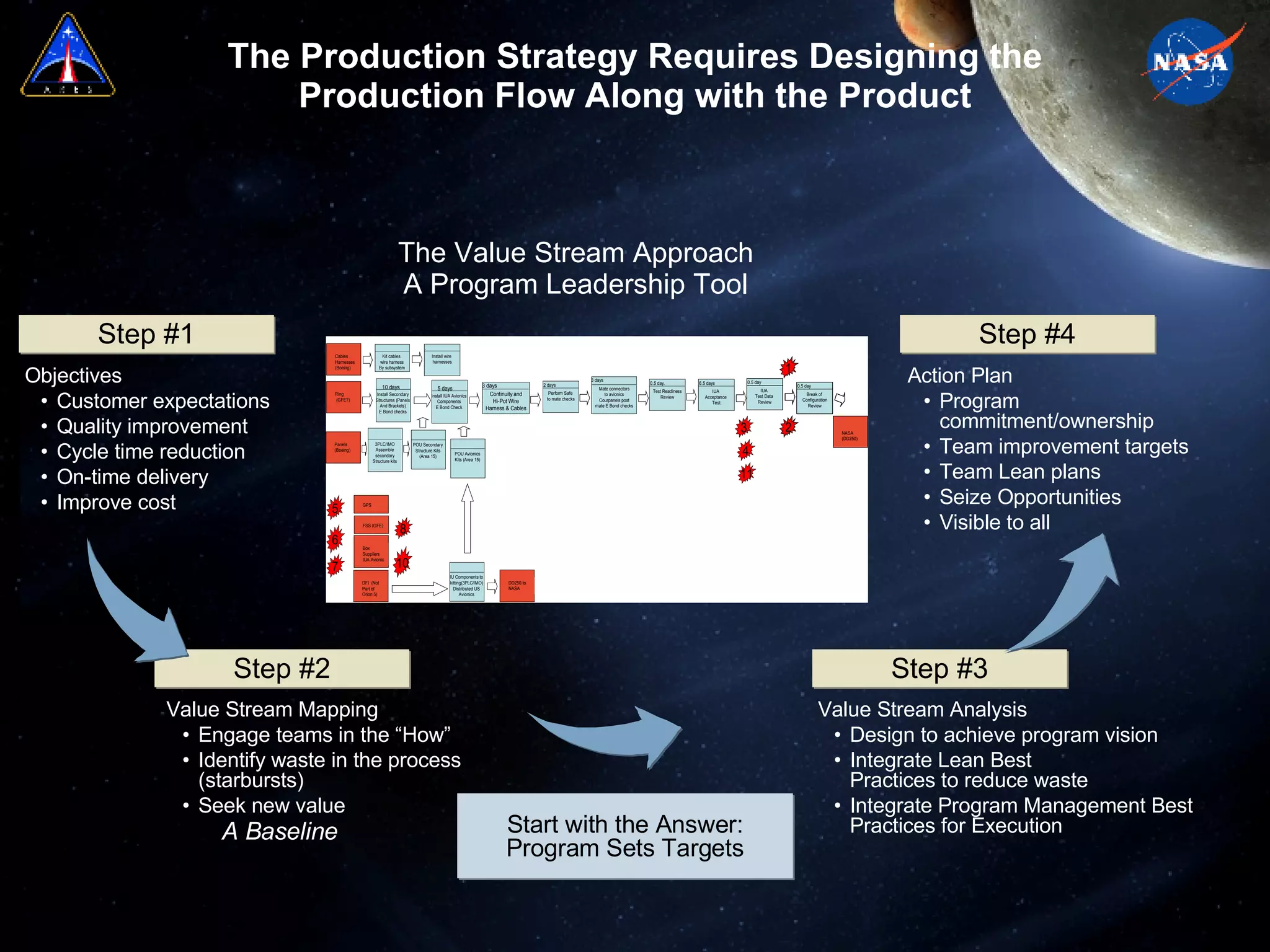

Boeing's team, led by Dwight Potter, is engaged in the development of a safe and affordable Ares I upper stage, focusing on producibility and manufacturing operations for NASA. Utilizing value stream mapping, they aim to enhance safety, efficiency, and innovation while reducing waste in manufacturing processes. Key objectives include optimizing costs, improving production flow, and integrating the supply chain to meet program goals.