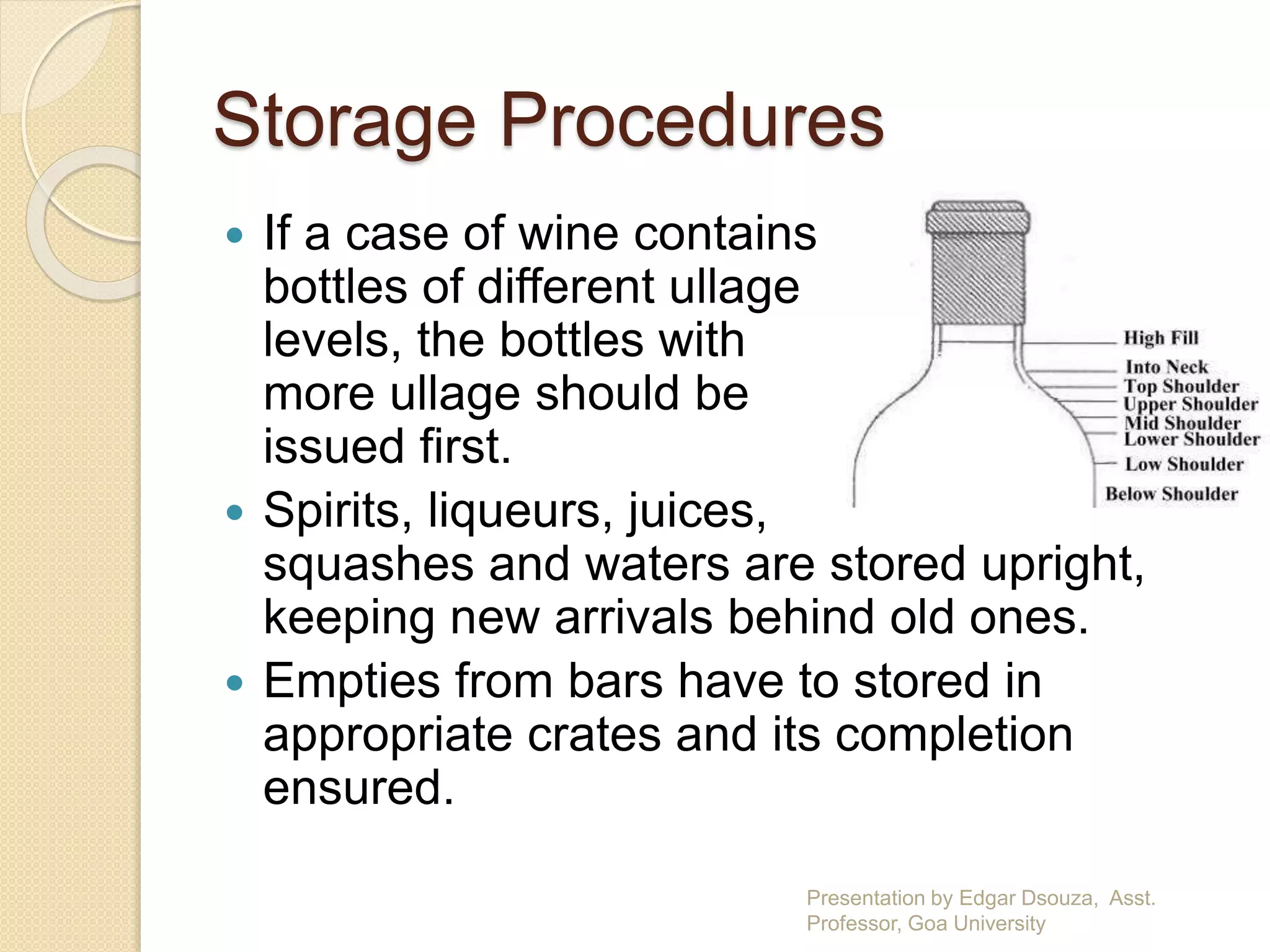

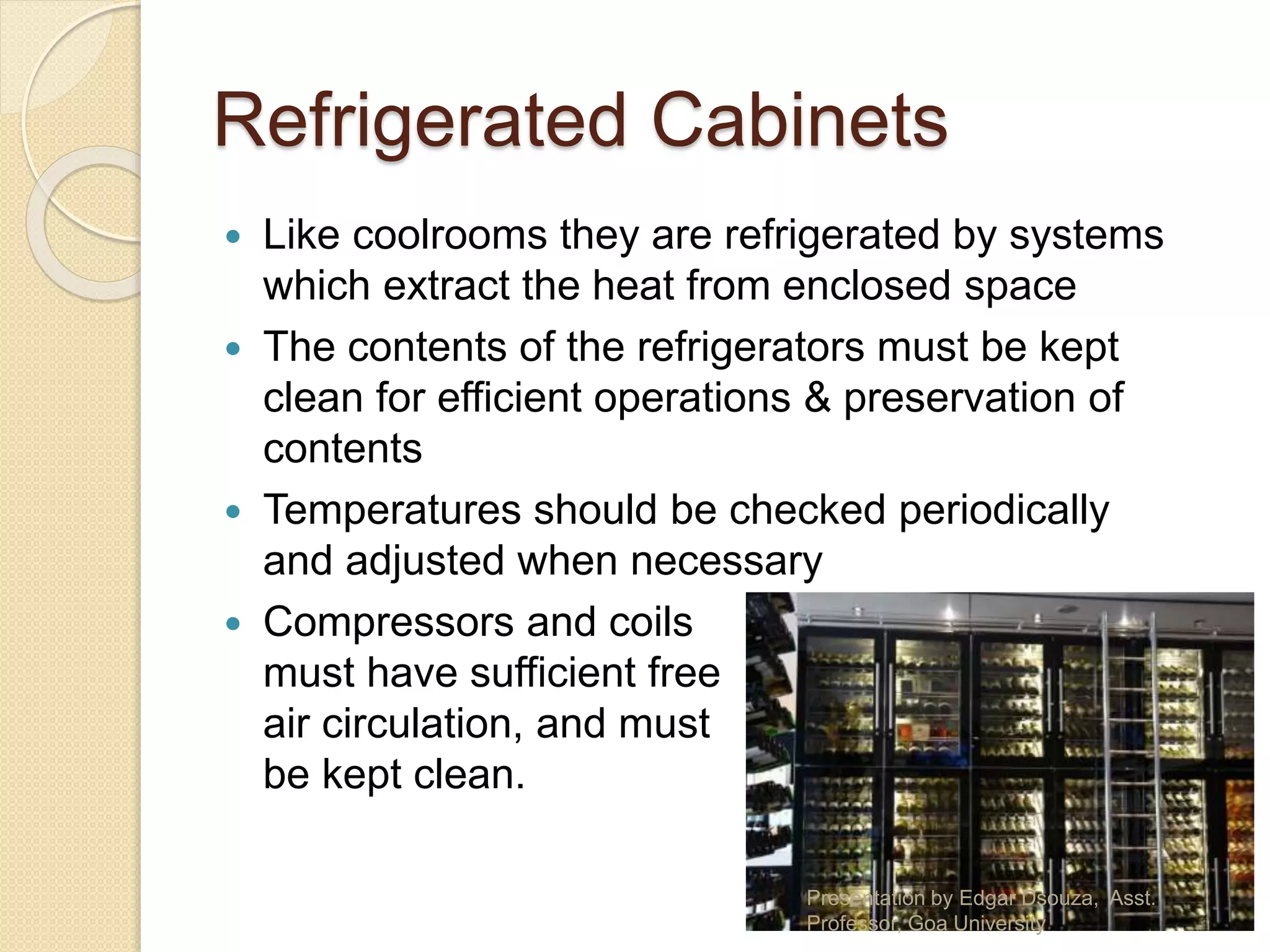

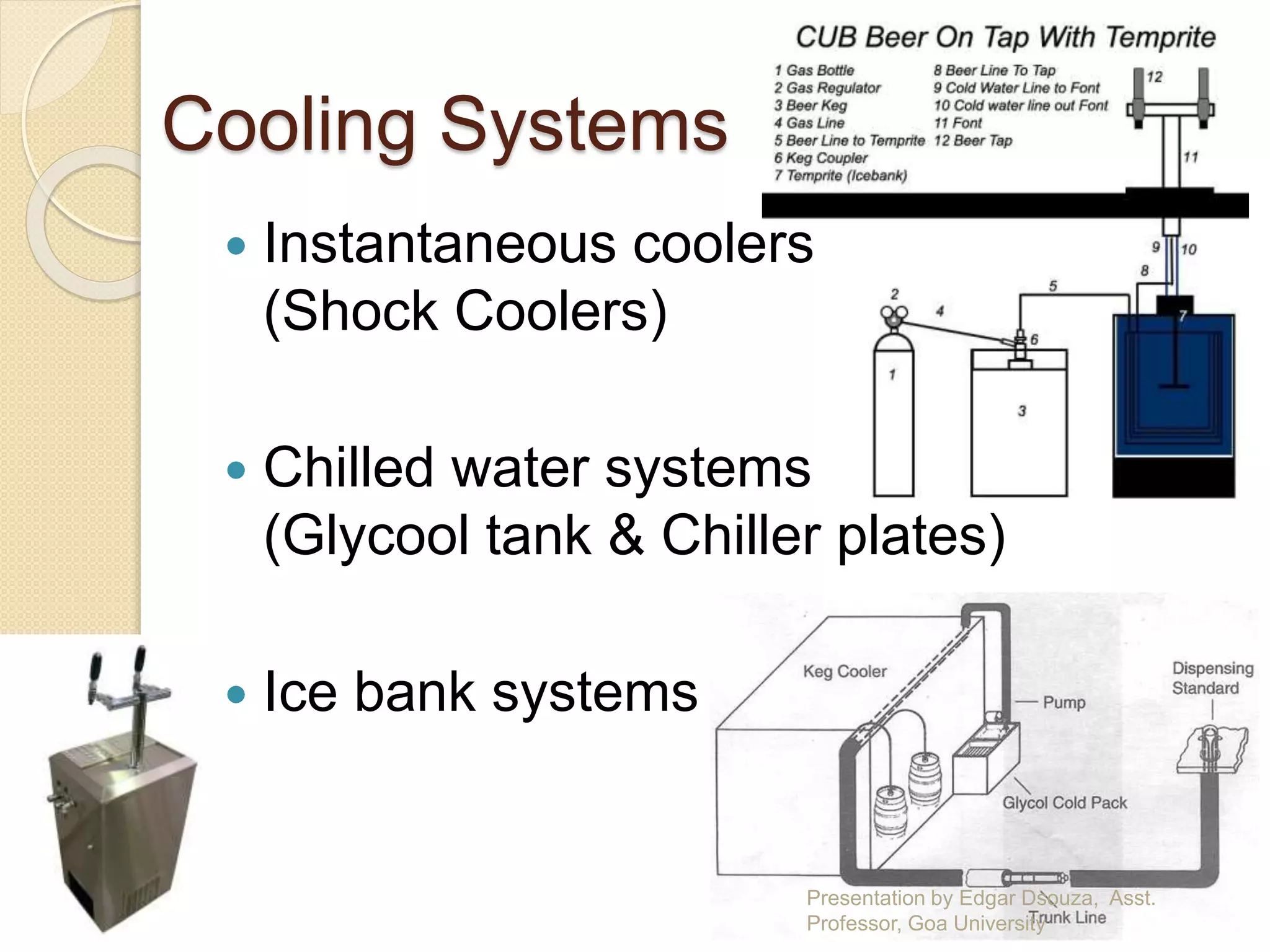

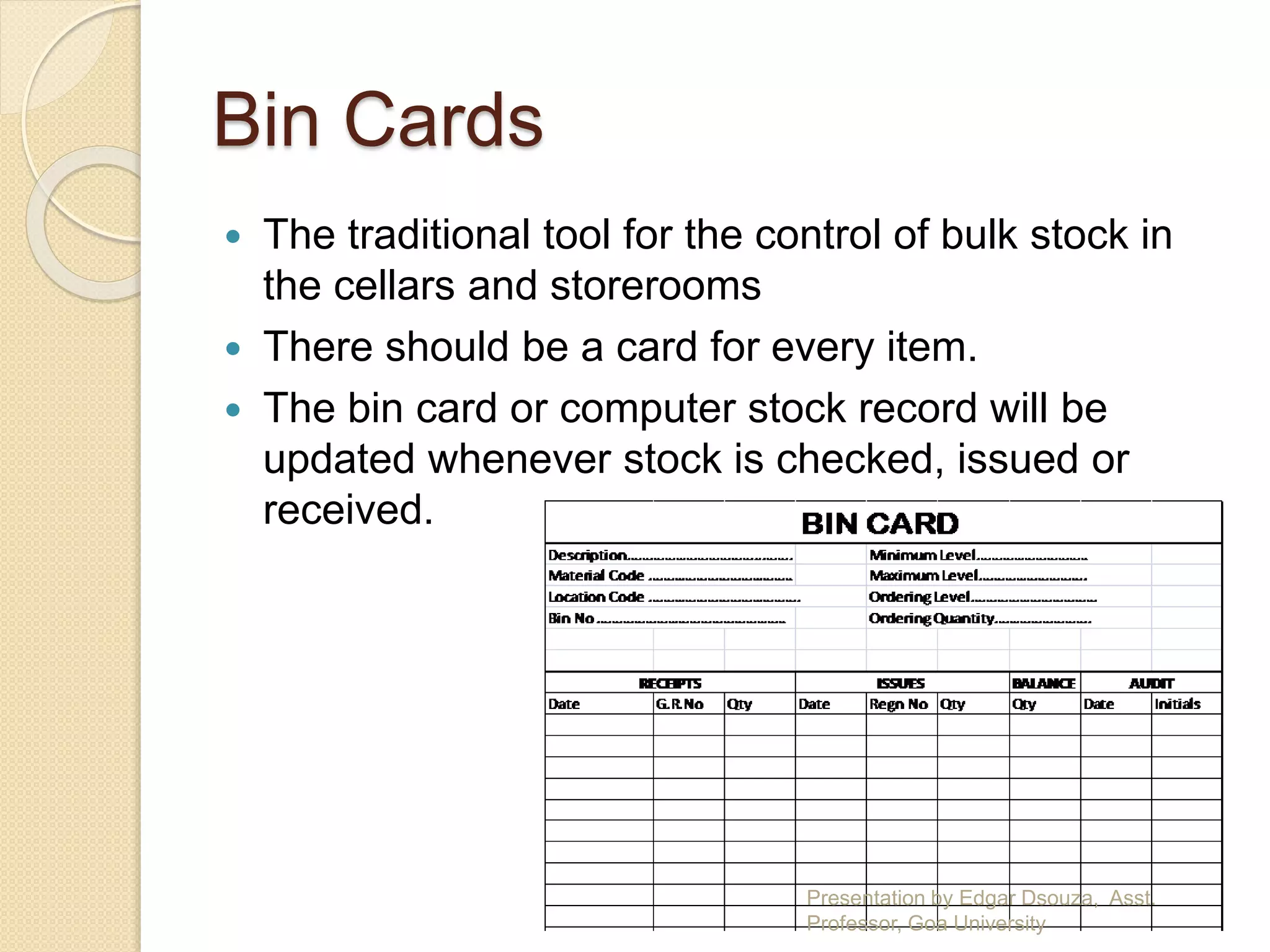

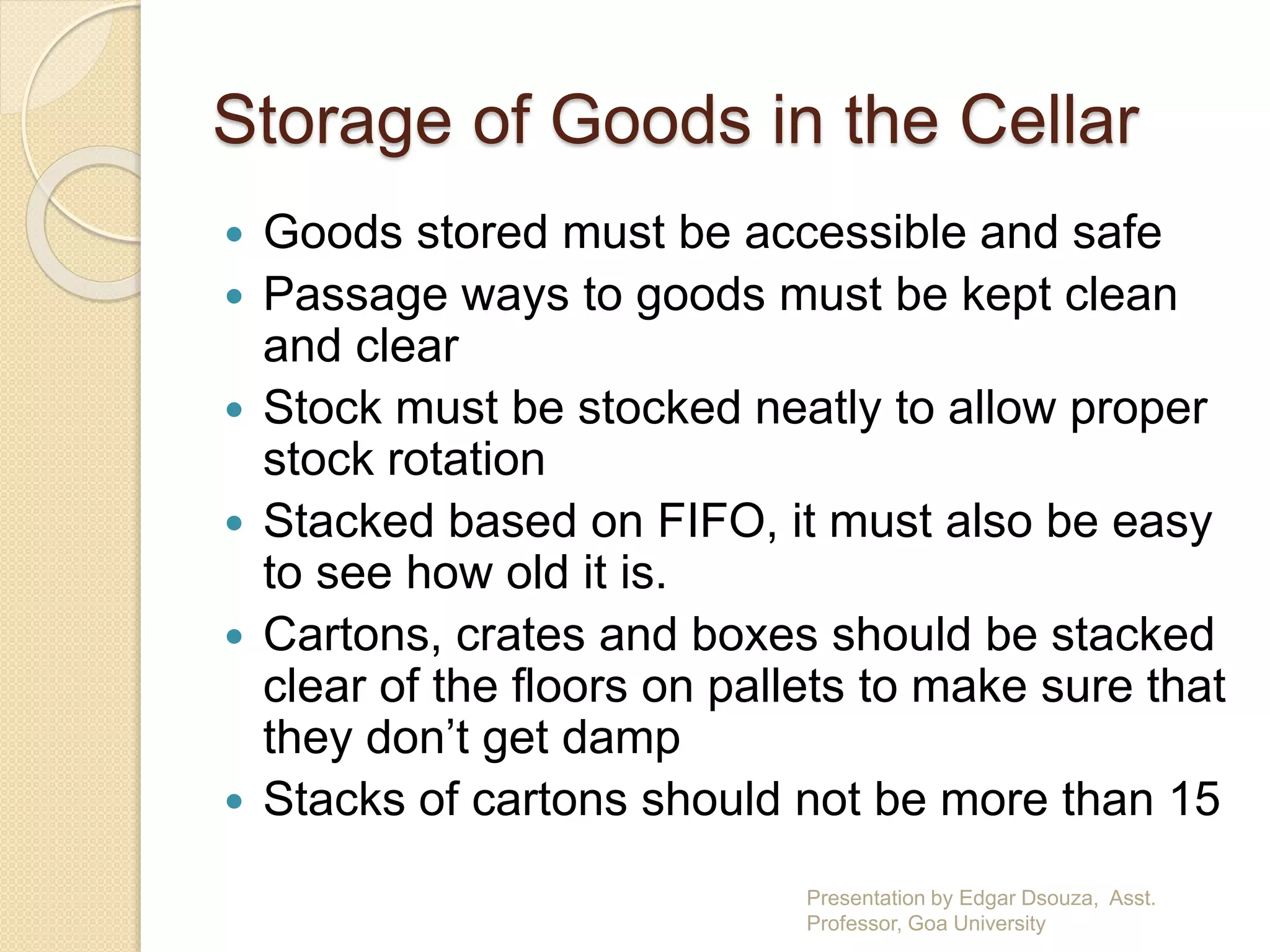

The document outlines the responsibilities of a cellar-man, detailing the management of alcoholic beverage storage, including optimal temperature conditions and safety procedures for both refrigeration systems and stock handling. It emphasizes the importance of maintaining quality through careful stock management, including proper storage techniques, regular inventory checks, and utilizing barcode systems for inventory control. Additionally, it underscores safety and maintenance protocols for refrigeration units and the necessity of keeping goods organized and accessible in the cellar.