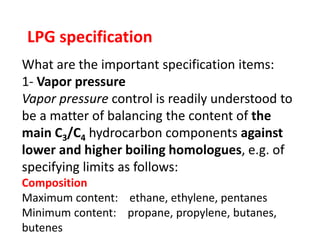

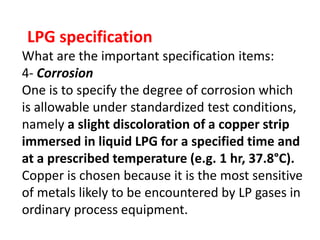

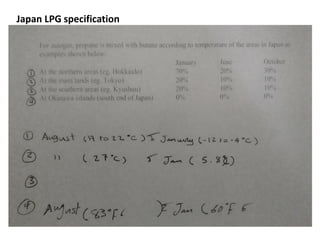

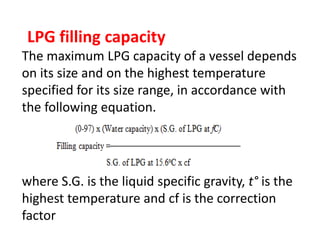

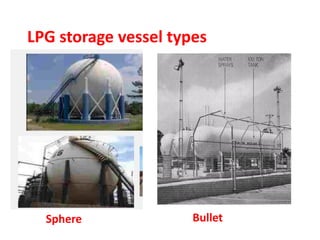

The document discusses key specifications for LPG, including vapor pressure, composition limits, non-volatile residue and contaminants, water content, toxicity and odor control, and corrosion resistance. It also covers LPG testing considerations, cylinder types and sizing, storage vessel types and capacities, and safety precautions related to LPG's flammability and asphyxiation hazards.