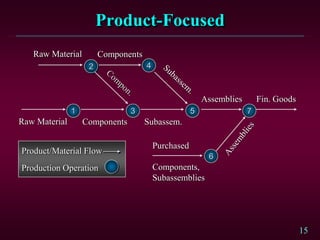

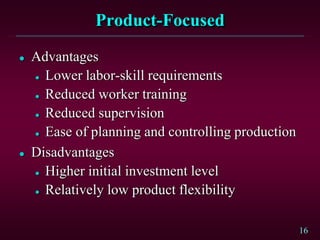

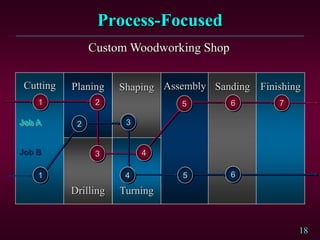

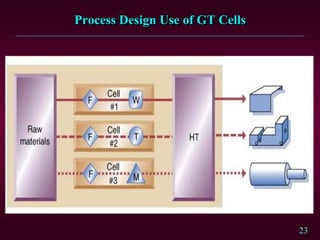

The document discusses process planning and design. It defines process planning as systematically determining the optimal methods for manufacturing a product economically and competitively. This involves selecting machines, operations sequence, inspections, and tools. Process design includes selecting the type of process, outsourcing plans, technology/automation level, facility layout, work routing, equipment, and integrating process and product design. Major factors affecting process design are discussed like the nature of demand, degree of vertical integration, flexibility, automation, and quality needs. Different types of process designs like product-focused, process-focused, and group technology are also summarized.