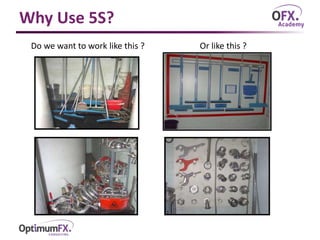

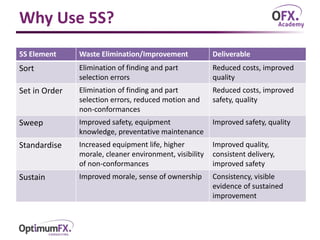

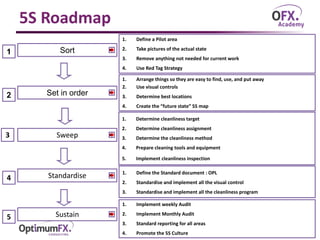

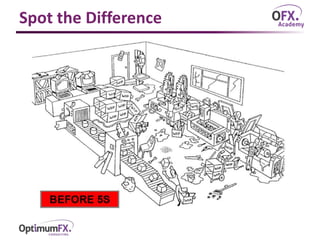

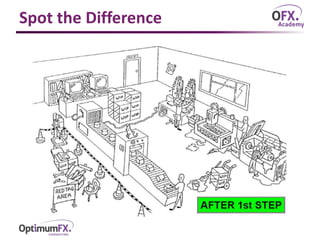

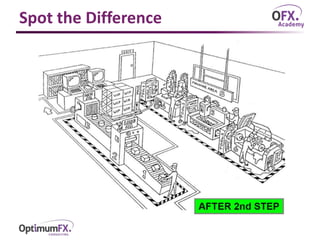

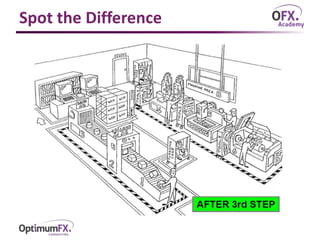

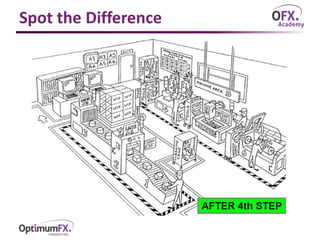

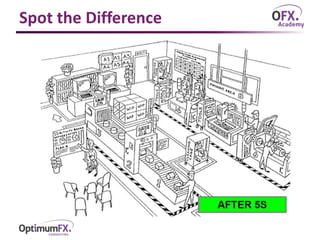

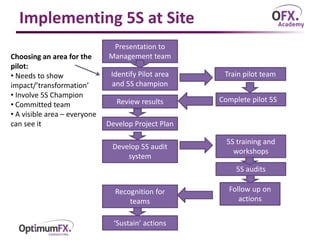

The document outlines the 5s methodology for enhancing workplace organization through five stages: sort, set in order, sweep, standardize, and sustain. Implementing 5s leads to benefits such as improved safety, productivity, customer confidence, and employee morale. A structured roadmap is provided for implementation, including training, audits, and the importance of visible transformation in the chosen pilot area.