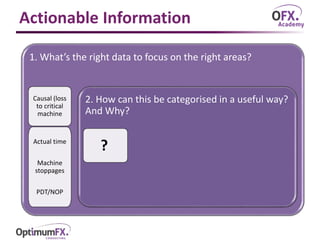

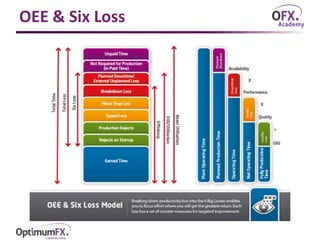

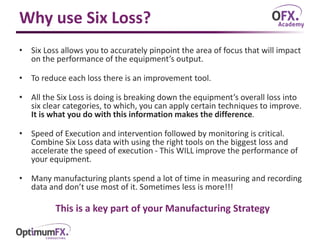

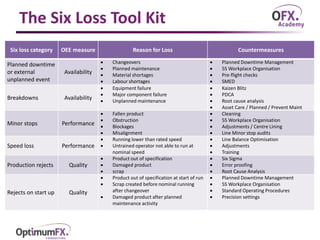

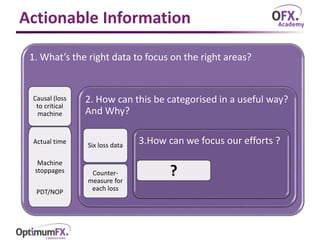

The document discusses improving packaging line performance by identifying and utilizing the correct data through drill-down analysis, emphasizing the importance of actionable information. It introduces the concept of 'Six Loss,' which breaks down equipment loss into six categories for targeted improvement strategies. The key takeaway is that effective use of data and timely interventions can significantly enhance performance in manufacturing environments.