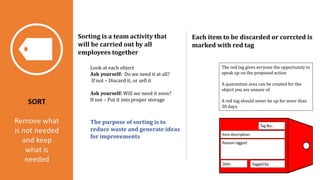

The document discusses the 5S methodology, which aims to create a clean, organized, and safe workplace. It defines 5S as resulting in an optimized and productive work environment with reduced waste. The 5 pillars of 5S - Sorting, Set In Order, Shining, Standardizing, and Sustaining - are described as simple steps to implement visual control and lean production. Implementing 5S brings benefits like improved safety, fewer breakdowns, better organization with no searching, and an enhanced work environment. An 8-step process for 5S implementation is also outlined.