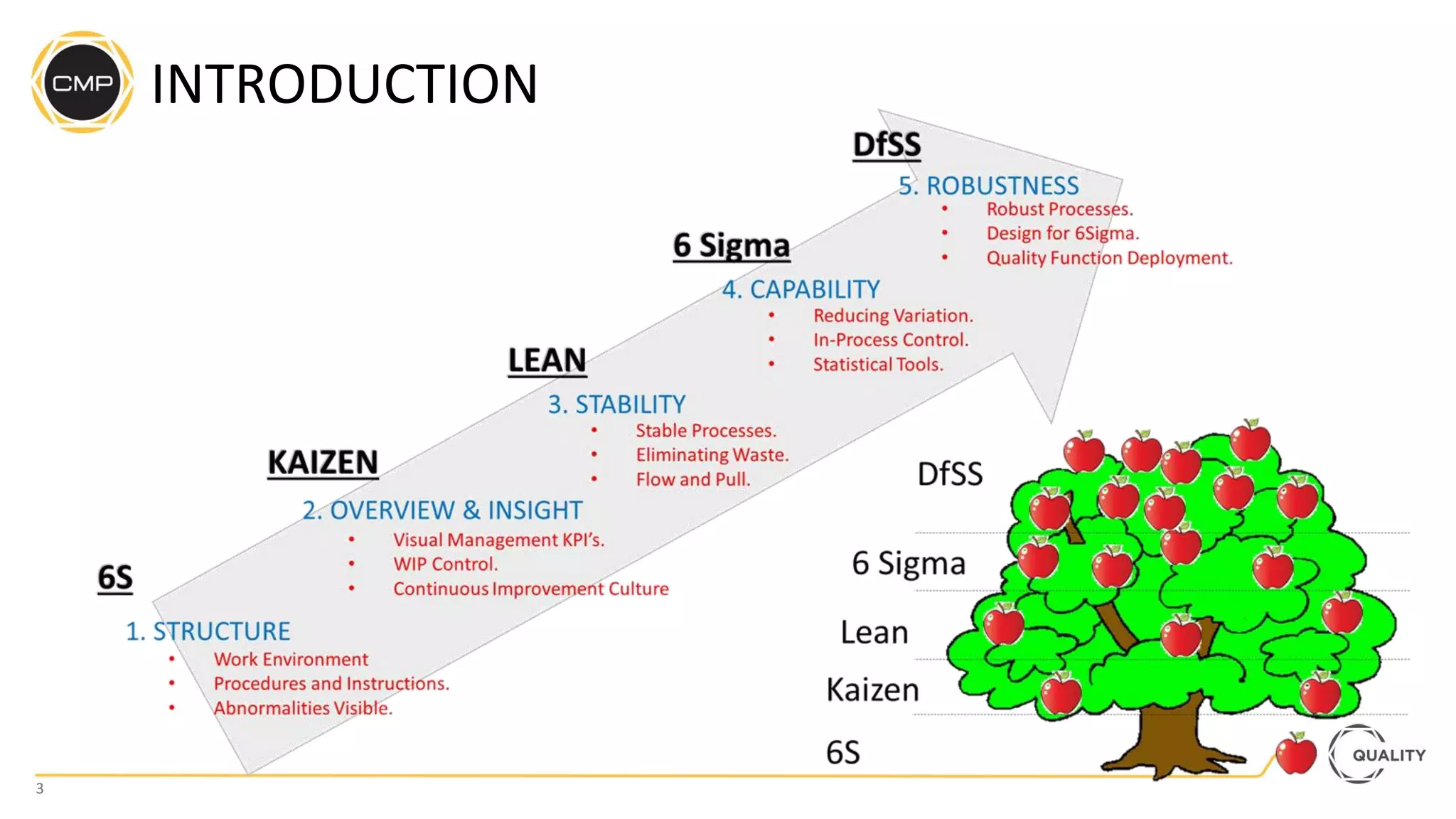

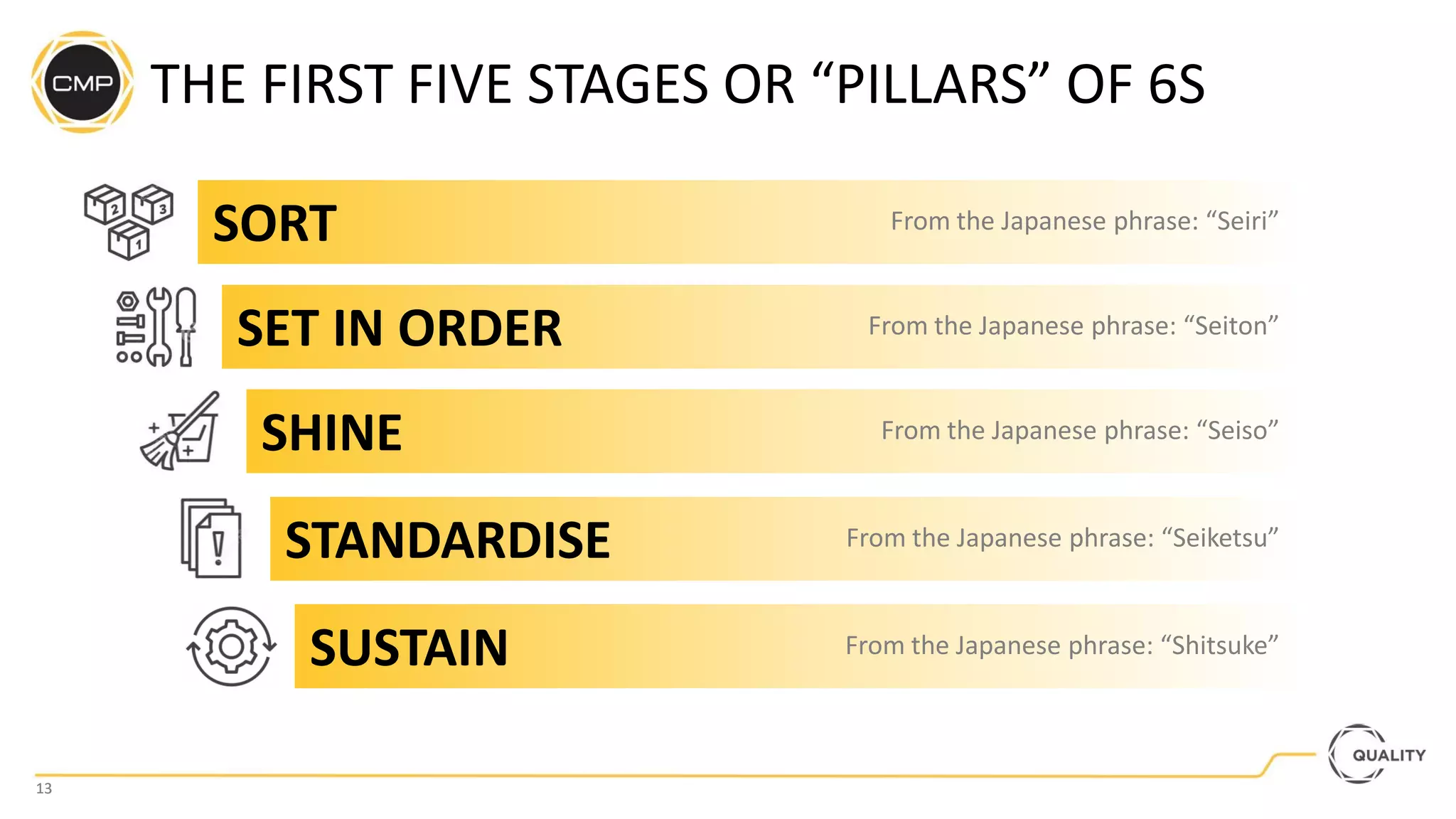

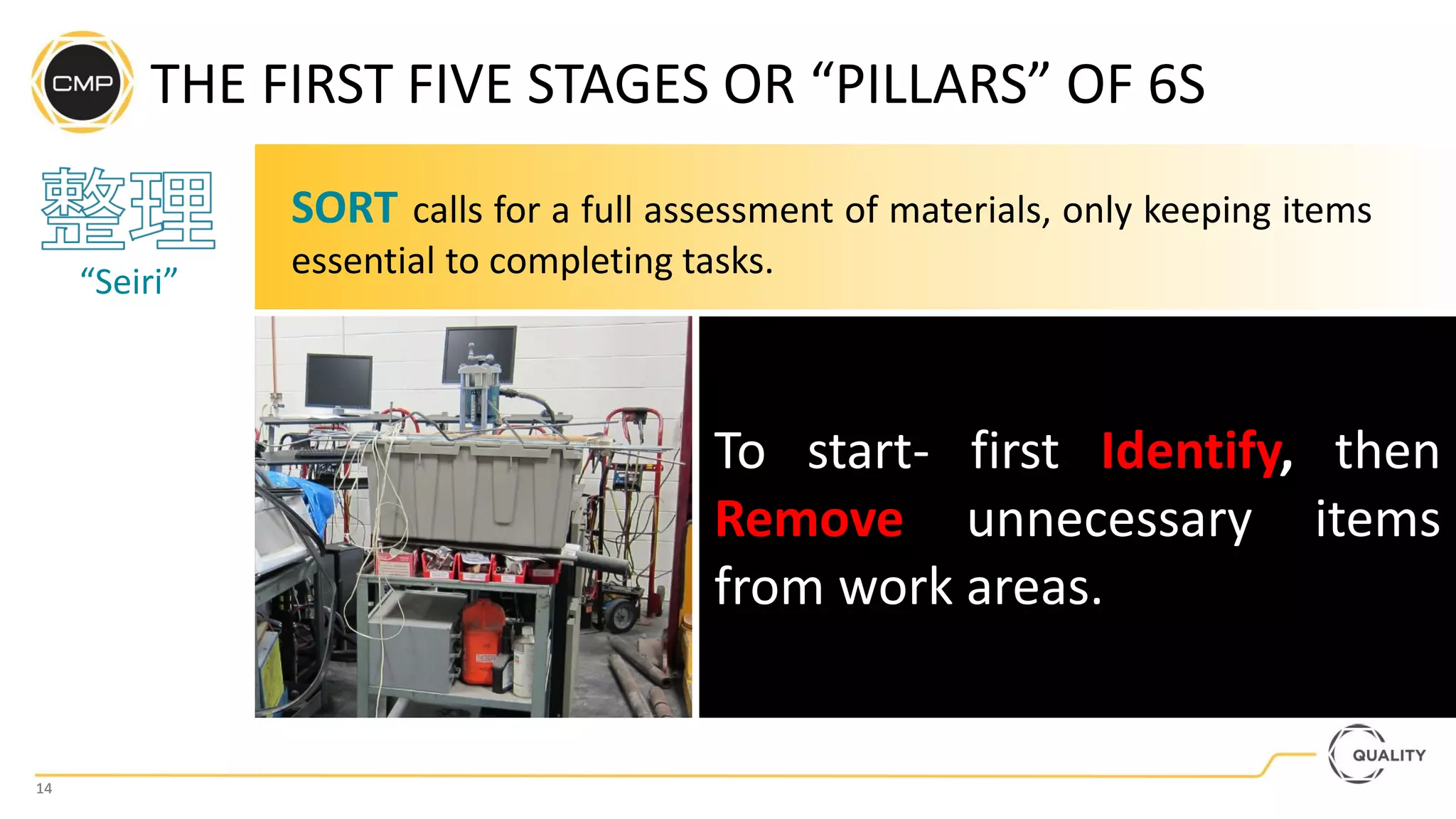

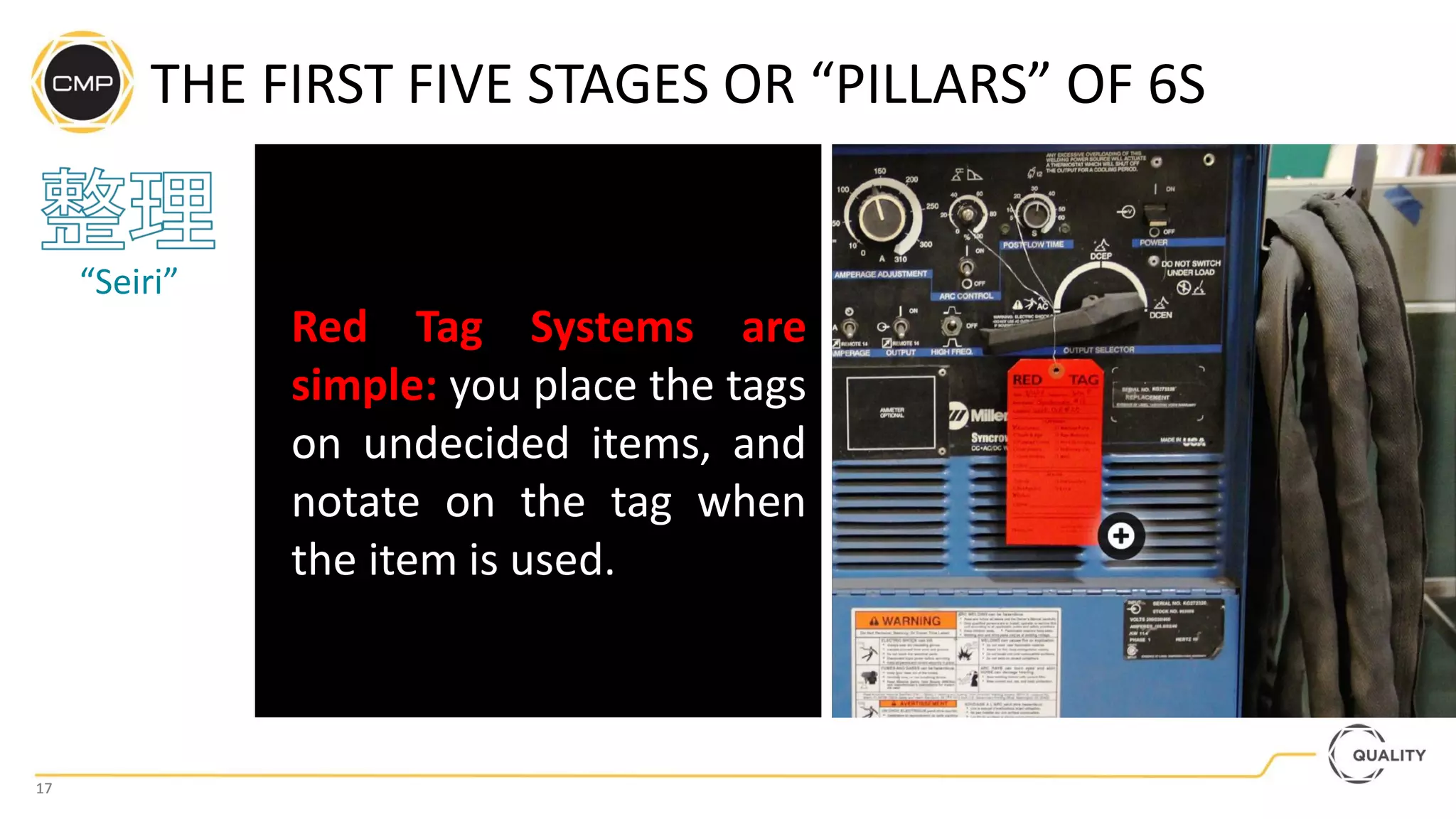

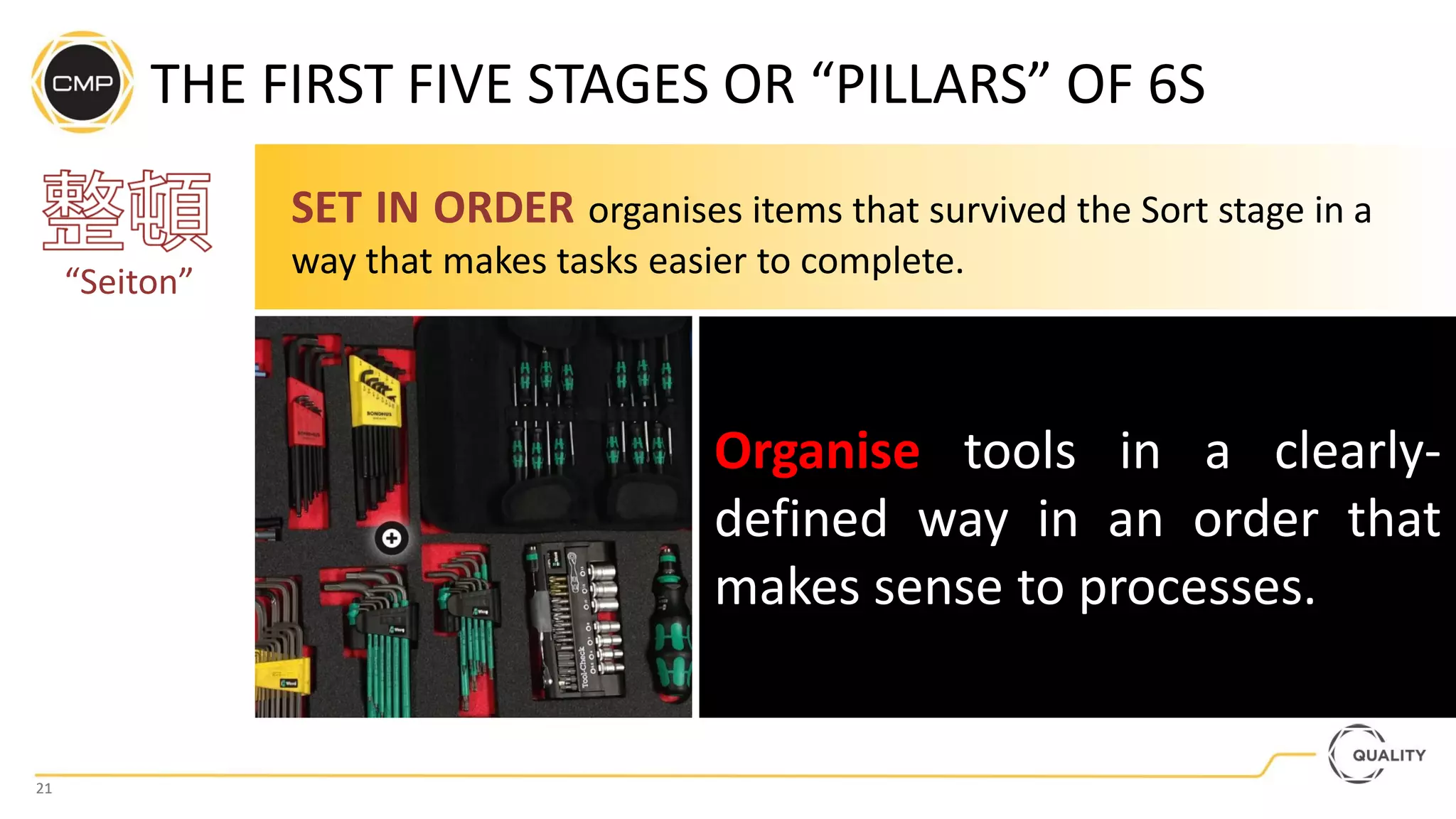

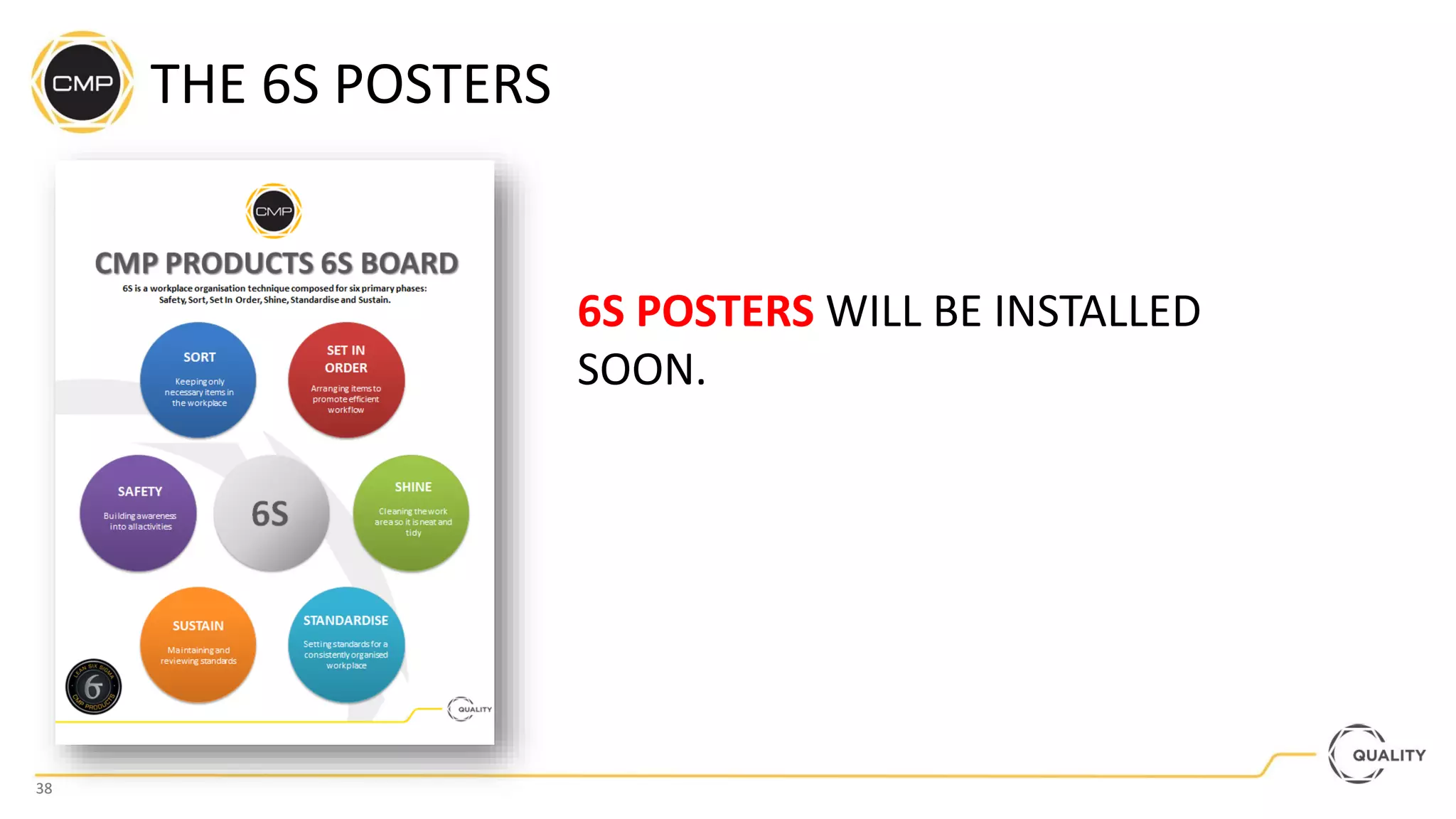

The document provides an introduction to the 6S methodology for organizing and standardizing a workplace. It explains that 6S was developed by Toyota and involves 5 stages ("Sort", "Set In Order", "Shine", "Standardize", "Sustain") plus a sixth stage of Safety. Each stage is described in 1-2 sentences. The goals of 6S are to remove unnecessary items, systematically improve processes, and establish standards to maximize efficiency and productivity.