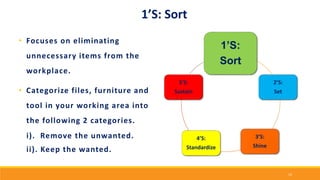

The 5S methodology is a system for organizing and managing a work area using five principles: sort, set in order, shine, standardize, and sustain. The goals of 5S are to improve efficiency, reduce waste, improve safety, and create a more organized work environment through employee participation. The 5S process involves sorting through all items in a work area to remove unnecessary items, setting remaining items in designated places, regularly cleaning the area, standardizing processes and visual controls, and sustaining the new systems through habit and audits. Examples show the transformation of work areas from cluttered and disorganized to clean, well-labeled, and efficiently arranged.