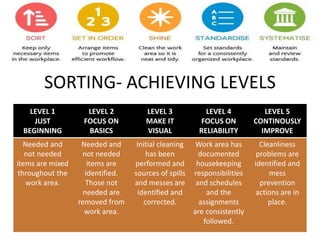

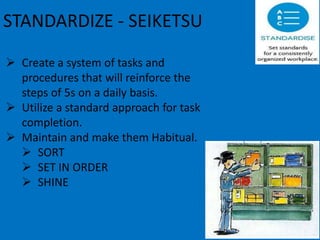

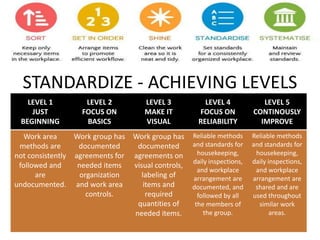

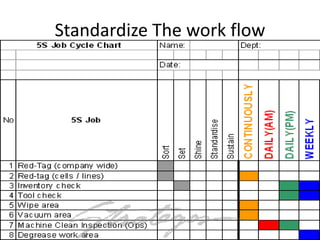

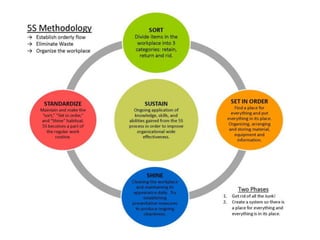

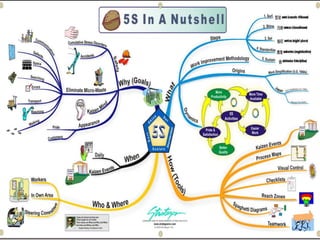

This document outlines the 5S methodology for organizing and standardizing a workplace. The 5S steps are: Sort, Set in Order, Shine, Standardize, and Sustain. For each step, the document defines the key activities and provides levels for achieving the goals of that step, from just beginning to continuously improving. Implementing 5S is intended to create a more efficient work environment through eliminating waste, improving storage of needed items, maintaining cleanliness and safety, and sustaining high standards of organization.