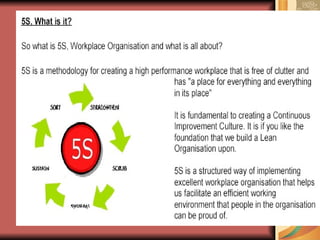

1. The 5S methodology focuses on workplace organization and cleanliness to identify waste and improve visibility of operations.

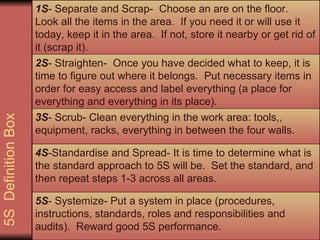

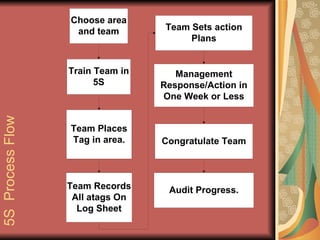

2. Each S represents a progression from separating and removing unneeded items to standardizing processes and spreading best practices across all areas.

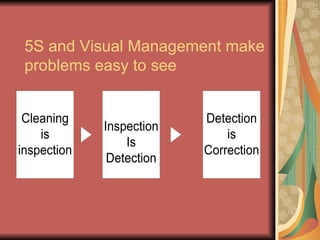

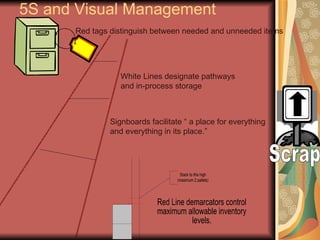

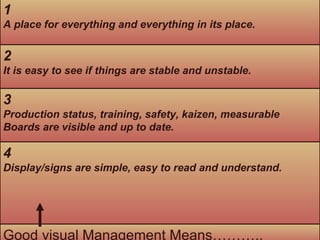

3. Implementing 5S and visual management through techniques like color-coding, signage, and display boards makes problems and status easily visible.