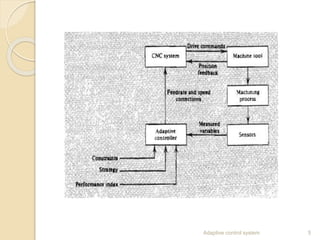

The document discusses adaptive control systems in CNC machining, highlighting their role in optimizing cutting speed and feed rates based on real-time feedback to enhance production efficiency and reduce costs. It outlines the three primary functions of adaptive control: identification, decision, and modification, as well as the types of systems, including those with optimization and constraints. While adaptive control offers benefits such as increased production rates and tool life, it also faces limitations such as the lack of suitable sensors and issues with interfacing with CNC units.