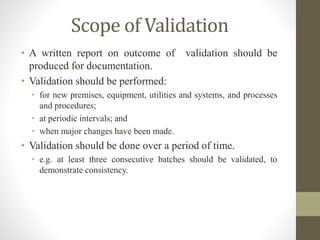

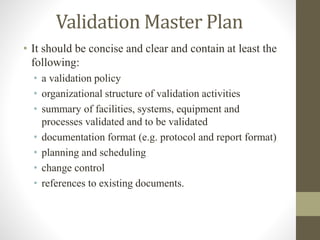

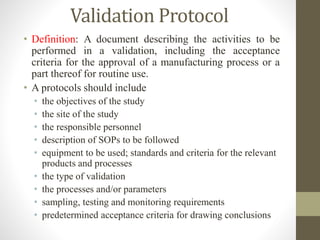

The document outlines pharmaceutical process validation, which ensures that procedures and equipment consistently produce quality products through defined protocols and scientific study. It covers the need for validation, associated documentation, stages of validation, and types like prospective and retrospective validation. Additionally, it addresses the importance of qualification and requalification, emphasizing that validation is essential for meeting regulatory requirements and optimizing production processes.