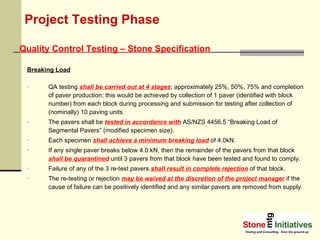

A testing program for stone adds value at all stages by ensuring a quality product fit for purpose. Testing determines inherent properties, design suitability, and qualitative analysis. Exploration testing quantifies the resource and potential products. Processing testing maximizes quality and recovery. Design testing validates engineering. Quarry development uses historical data to plan sustainably. Project testing specifies requirements through acceptance, production, and quality control testing to confirm properties and uniformity. A systematic specification protects suppliers and monitors quality.