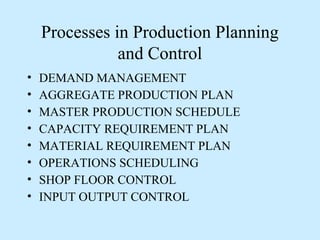

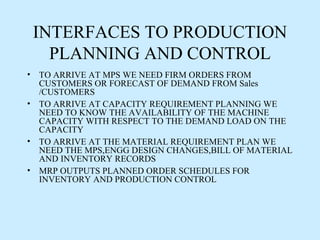

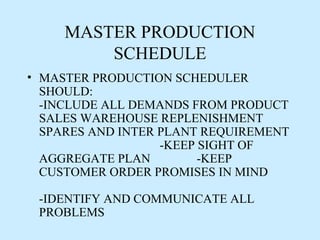

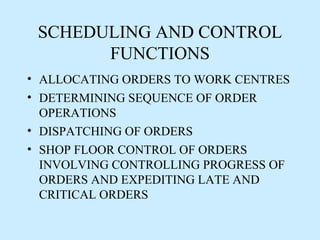

The document discusses manufacturing planning and control processes. It describes key functions like demand management, master production scheduling, capacity requirements planning, material requirements planning, operations scheduling, and shop floor control. The goal is to balance capacity and demand by planning production activities and controlling operations on the factory floor. Interfaces with other business functions are also important to coordinate planning across the organization.