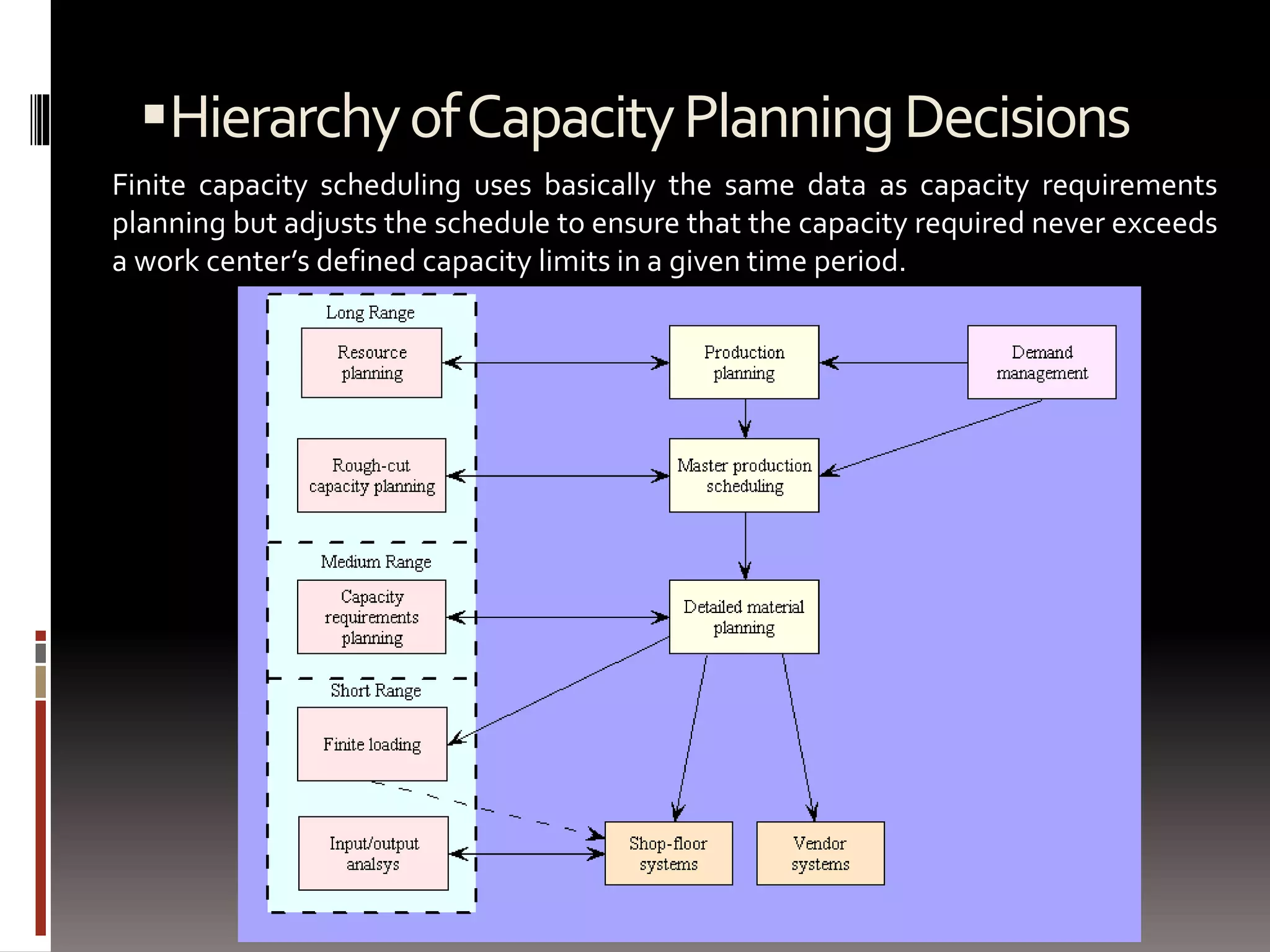

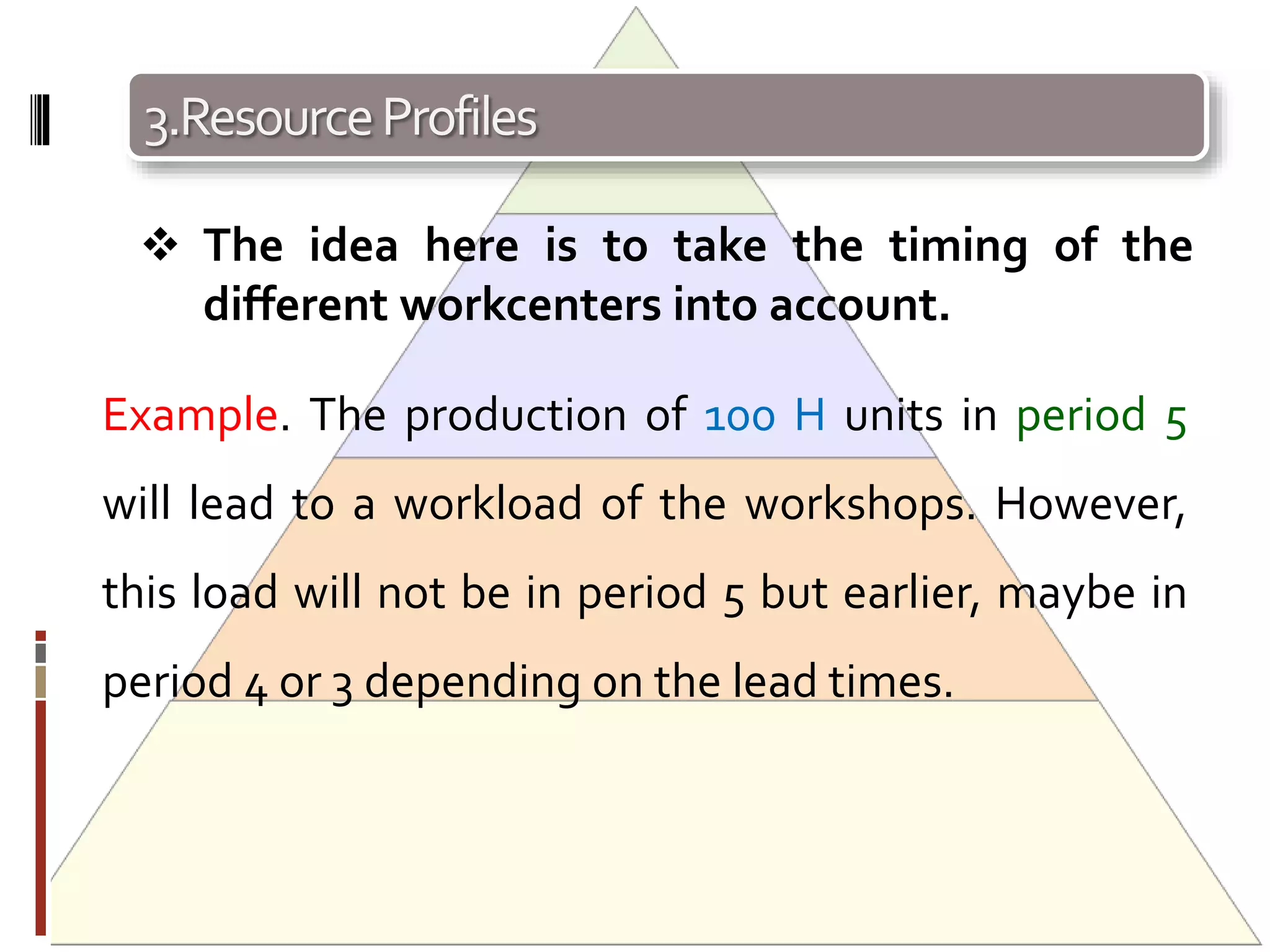

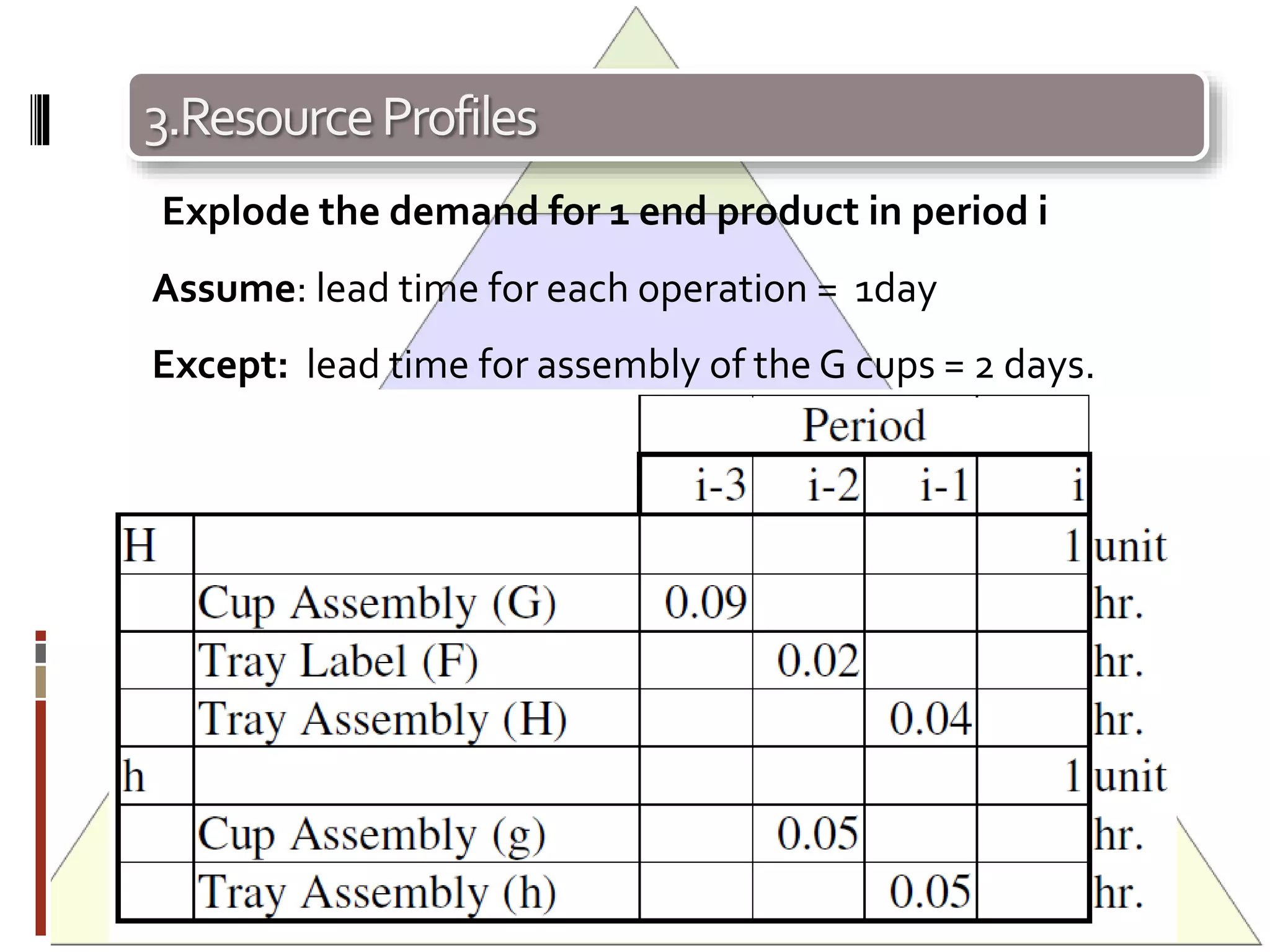

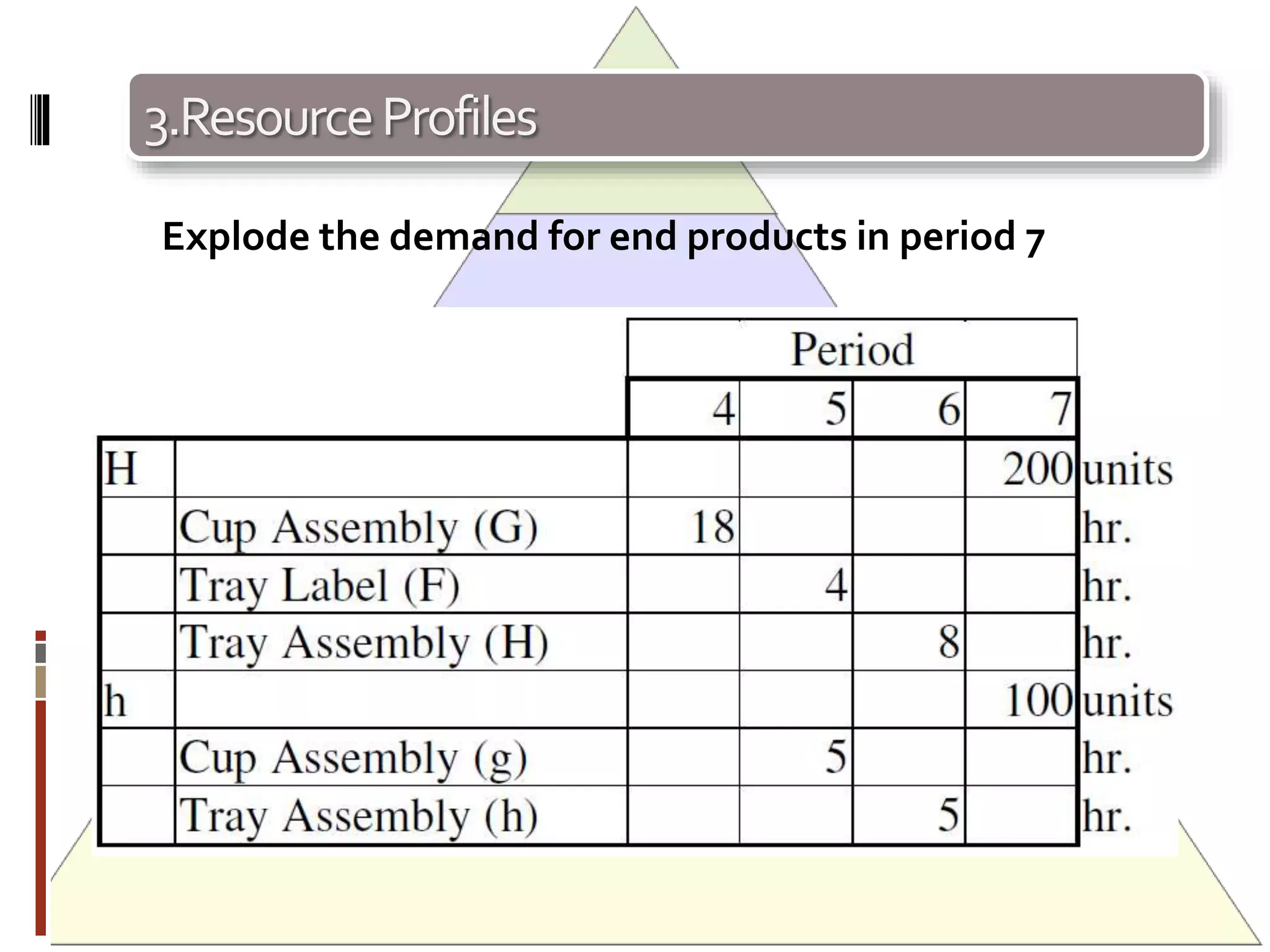

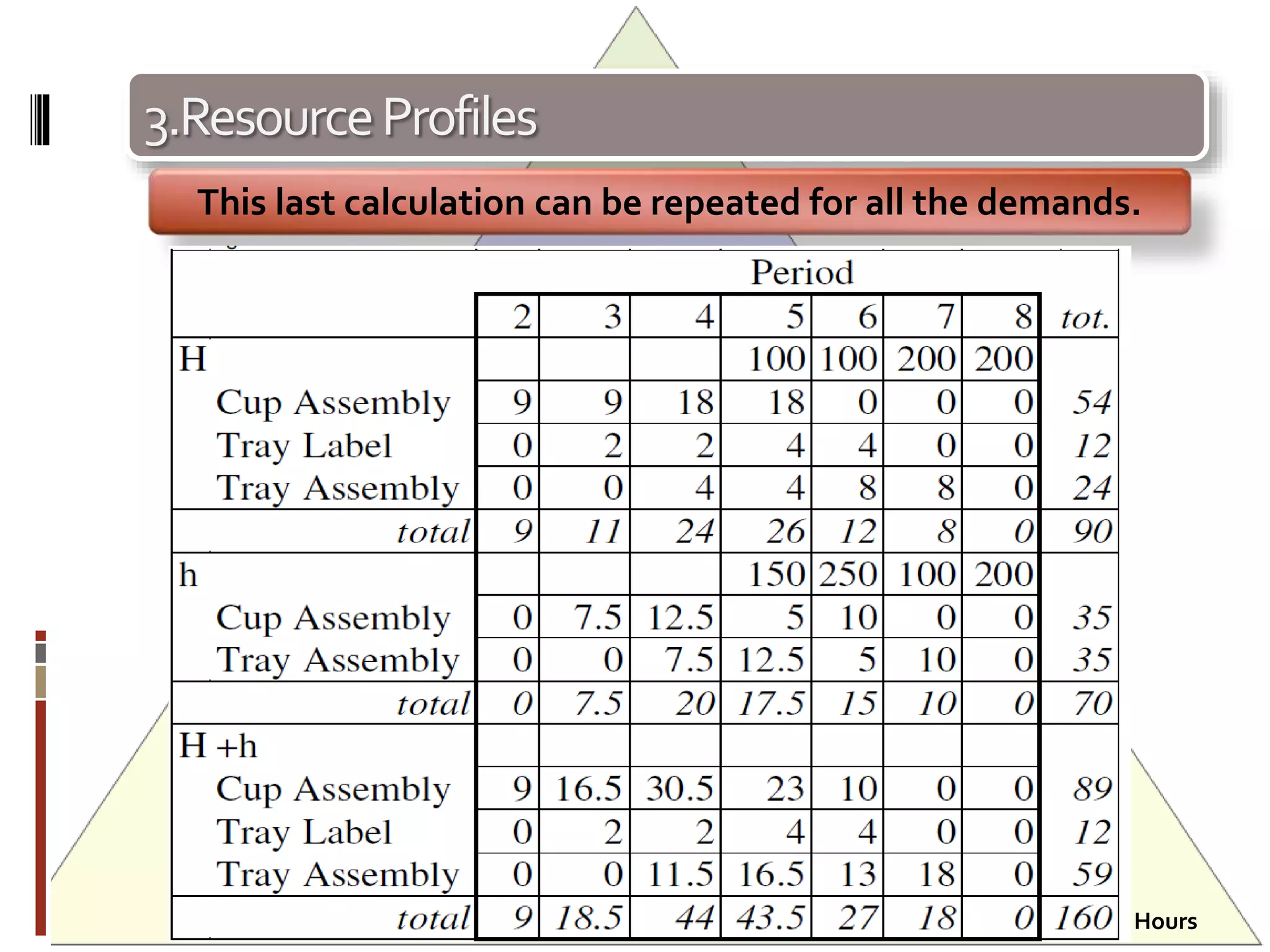

The document outlines various capacity planning techniques within manufacturing production control (MPC) systems, emphasizing the importance of effective management of resources to optimize production capabilities. It discusses methods such as capacity planning using overall factors (CPof), capacity bills, resource profiles, and capacity requirements planning (CRP), providing examples and case studies. Additionally, it highlights the hierarchy of decisions involved in capacity planning and the links between different MPC system modules.

![1.CapacityPlanningusingOverallFactors(CPOF).

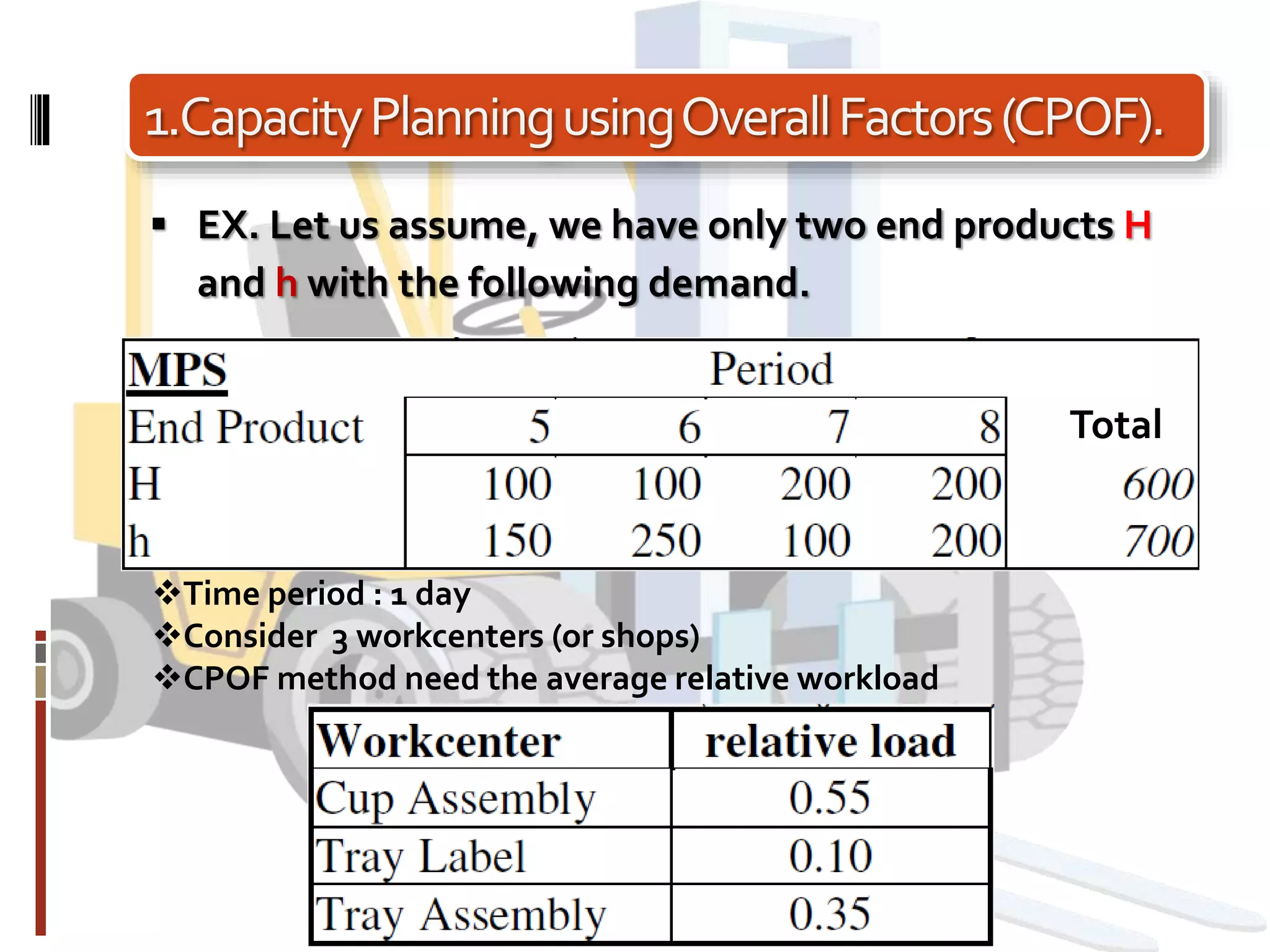

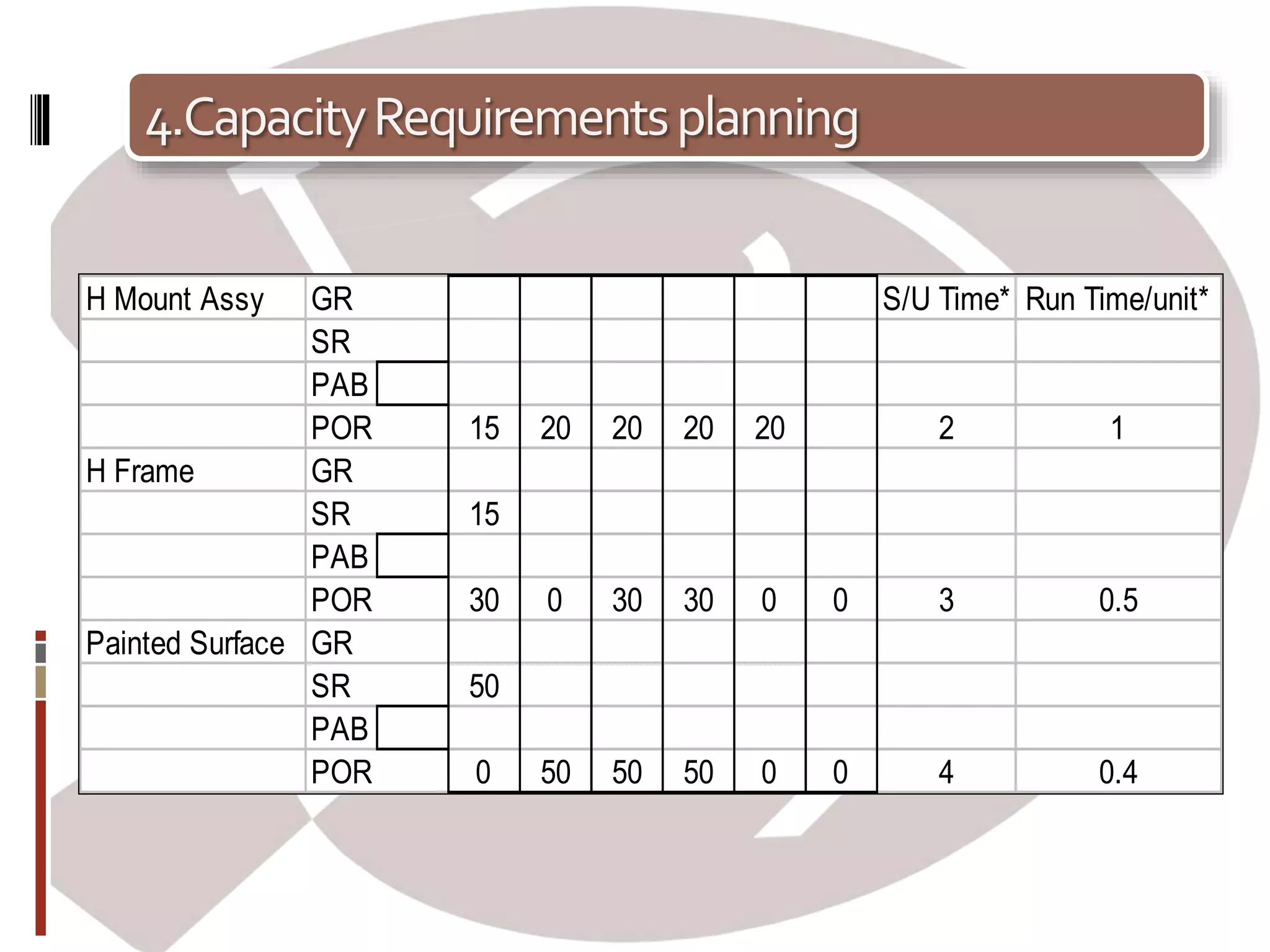

CPOF needTotal amount of resource for producing

one unit of each end products.

Assume the unit to be the working hour.

1 H requires 0.15 hour = 9 min.

1 h requires 0.1 hour = 6 min.

Workcenter load = [(H total capacity/product)x(H product/period)

+ (h total capacity/product )x (h product/period)] x relative load Eq.1](https://image.slidesharecdn.com/manufacturingplanningandcontrolsystems-140331165937-phpapp02/75/Manufacturing-planning-and-control-systems-14-2048.jpg)

![1.CapacityPlanningusingOverallFactors(CPOF).

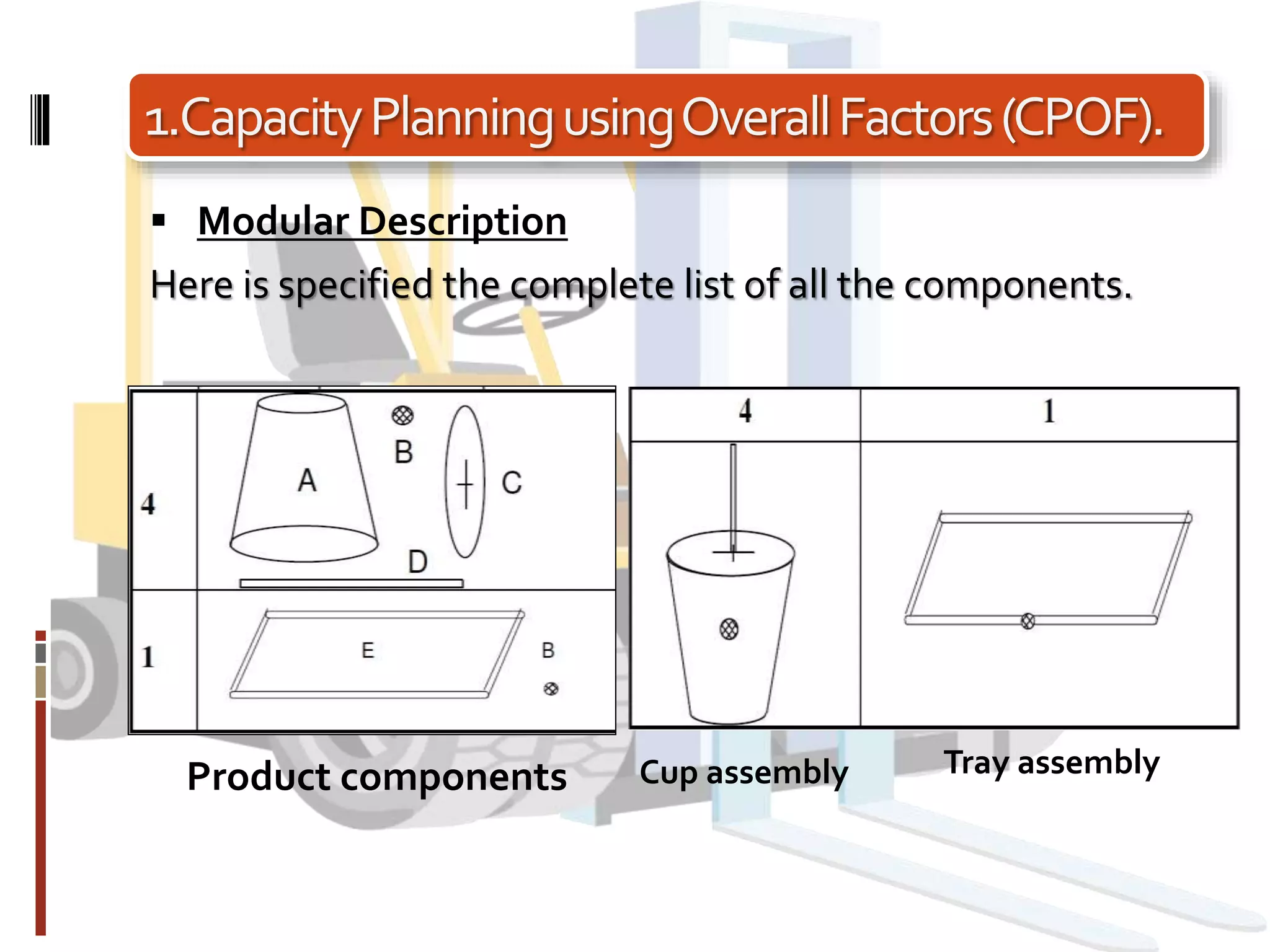

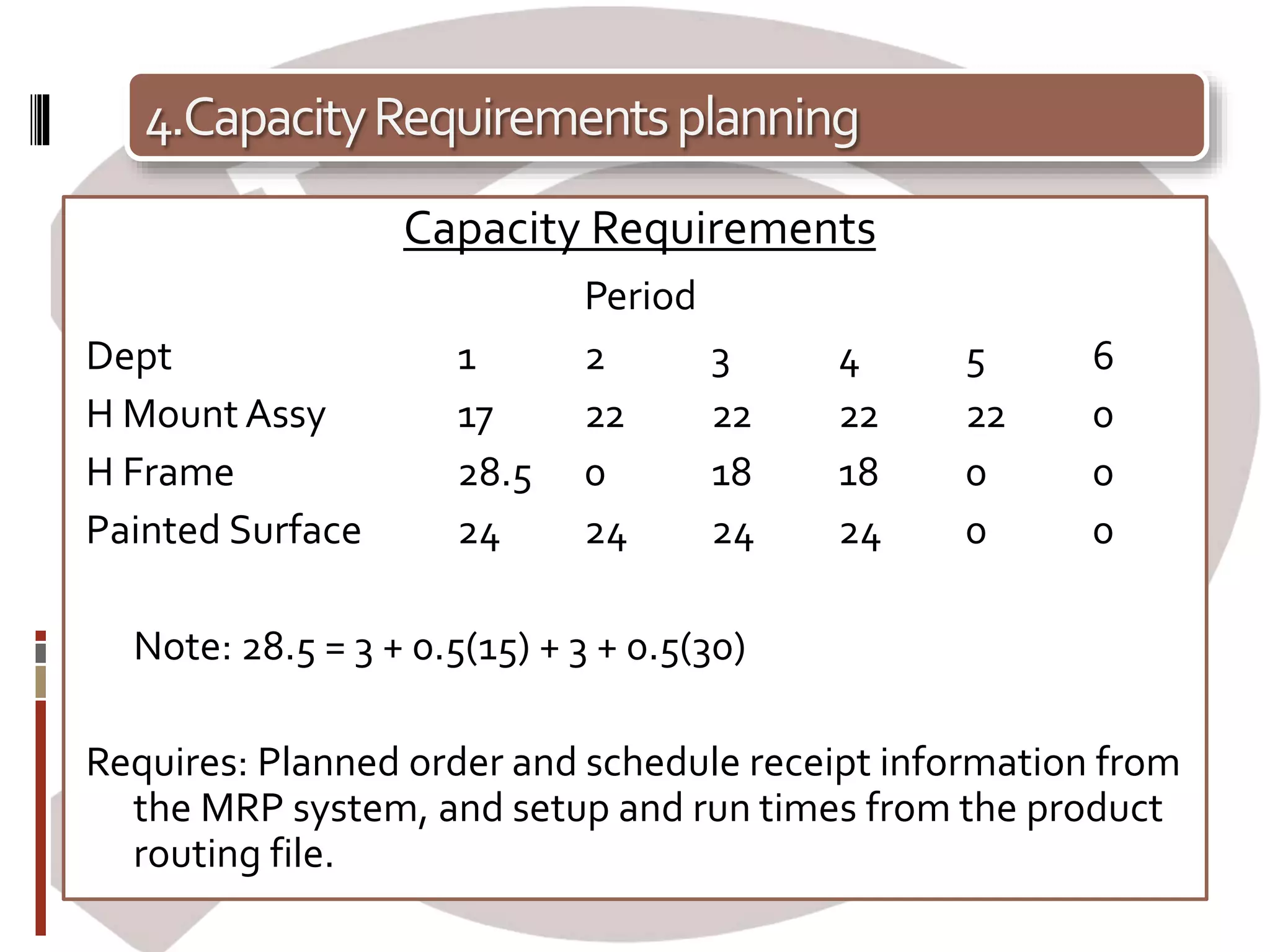

At period time 5

Cup assembly = [9*100+6*150]*0.55 = 990 min = 990/60 = 16.5 hours

Tray label = [9*100 +6*150]*0.10 = 180 min = 180/60 = 3 hours

Tray assembly = [9*100+6*150]*.35= 630 min = 630/60 = 10.5 hours

Total capacity = 16.5 + 3 + 10.5 =30 hours

The same calc with period 6,7,8

The method implicitly assume that for every production hour, 55 % are spent at

the Cup Assembly, 35 % at the Tray Assembly and 10 % at the Tray Label.

Total

55%

10%

35%

Hours](https://image.slidesharecdn.com/manufacturingplanningandcontrolsystems-140331165937-phpapp02/75/Manufacturing-planning-and-control-systems-15-2048.jpg)

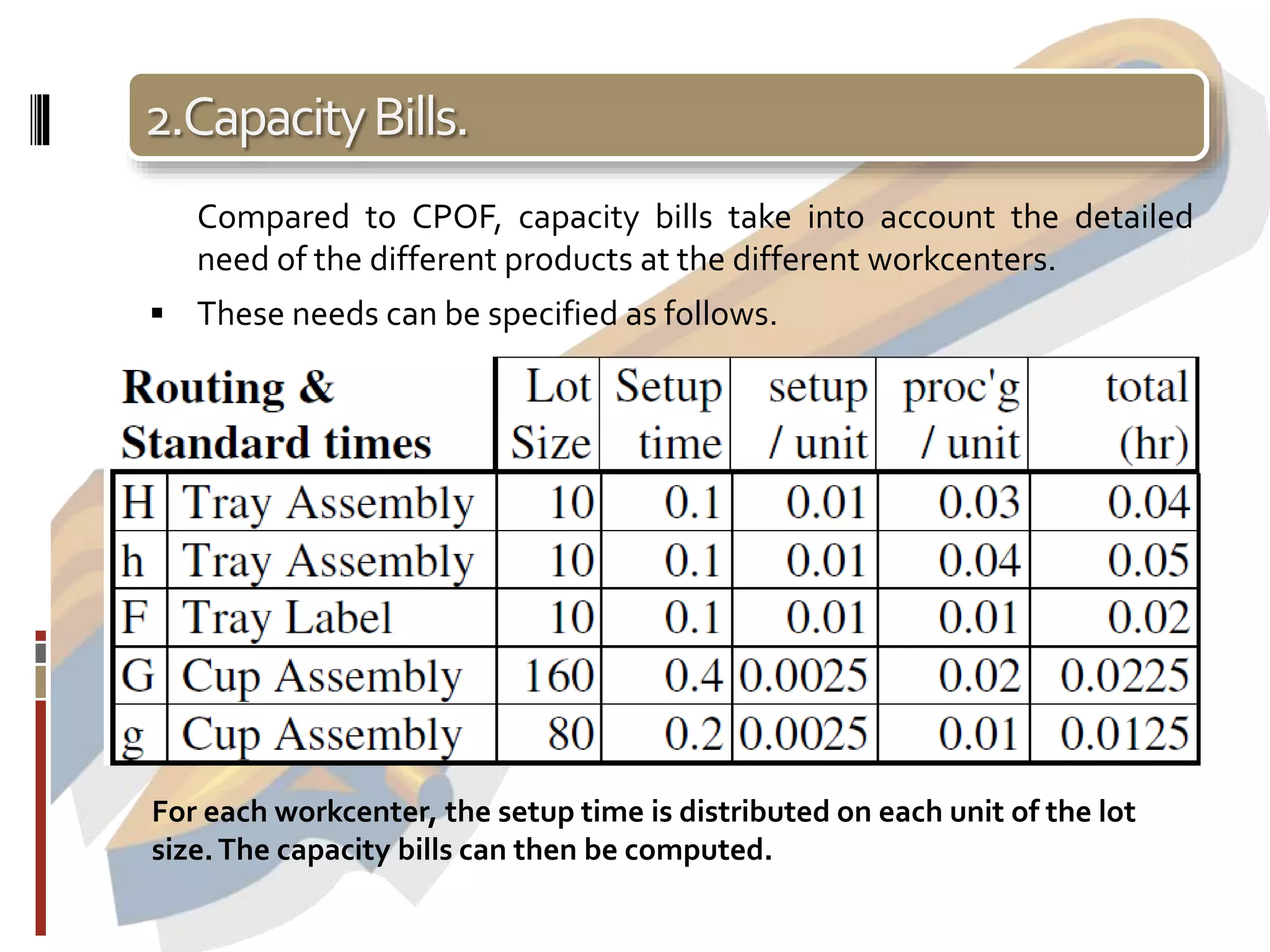

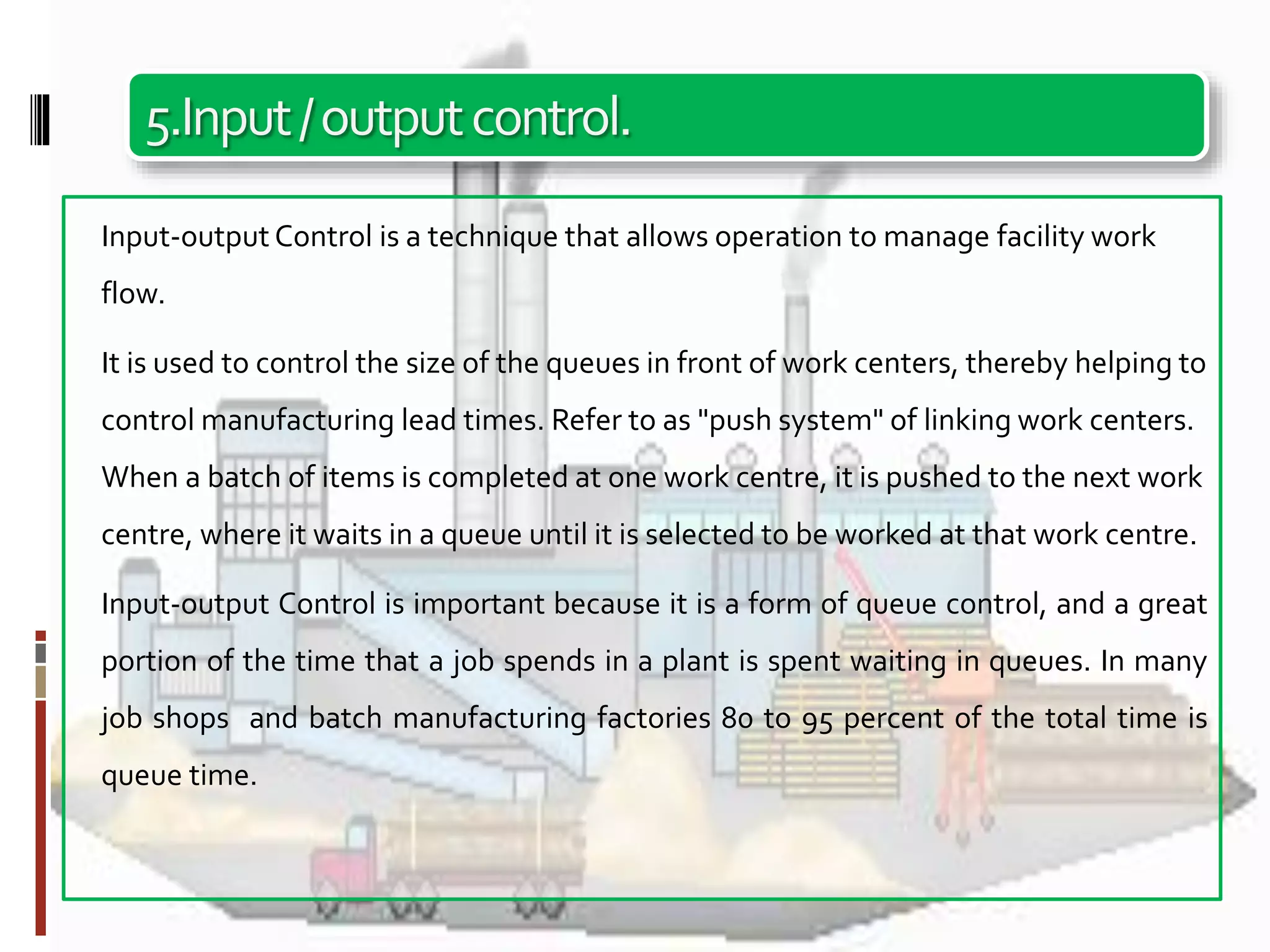

![2.CapacityBills.

Capacity requirements Using Capacity Bills

Workcenter load = [H capacity bill/product )x (H products/period)

+ (h capacity bill/product )x (h products/period)] Eq.2

At period time 5

Cup assembly = [0.09*100+0.05*150] = 16.5 hours

Tray label = [0.02*100 +0*150] = 2 hours

Tray assembly = [0.04*100+0.1*150]= 11.5 hours

Hours](https://image.slidesharecdn.com/manufacturingplanningandcontrolsystems-140331165937-phpapp02/75/Manufacturing-planning-and-control-systems-18-2048.jpg)

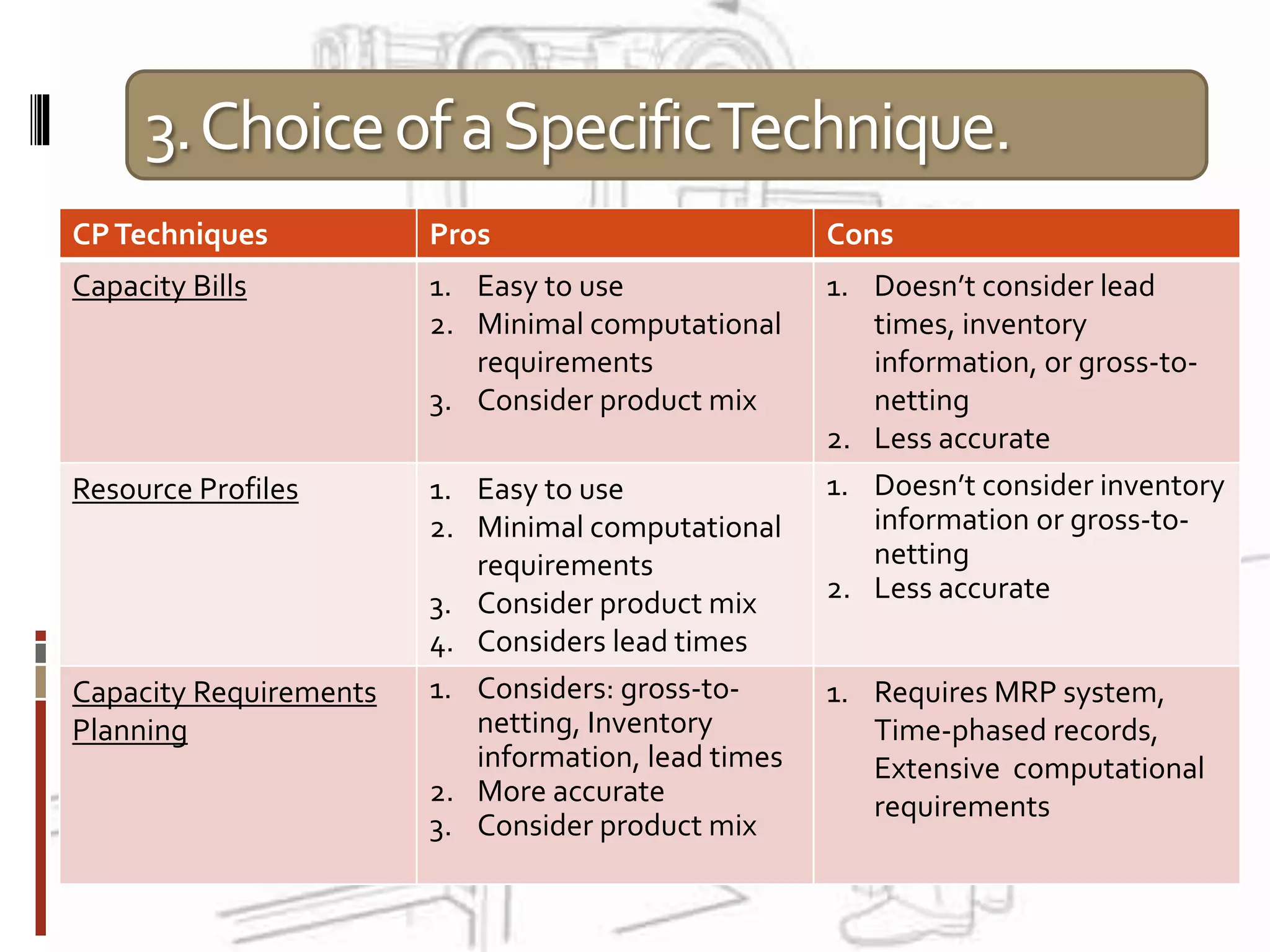

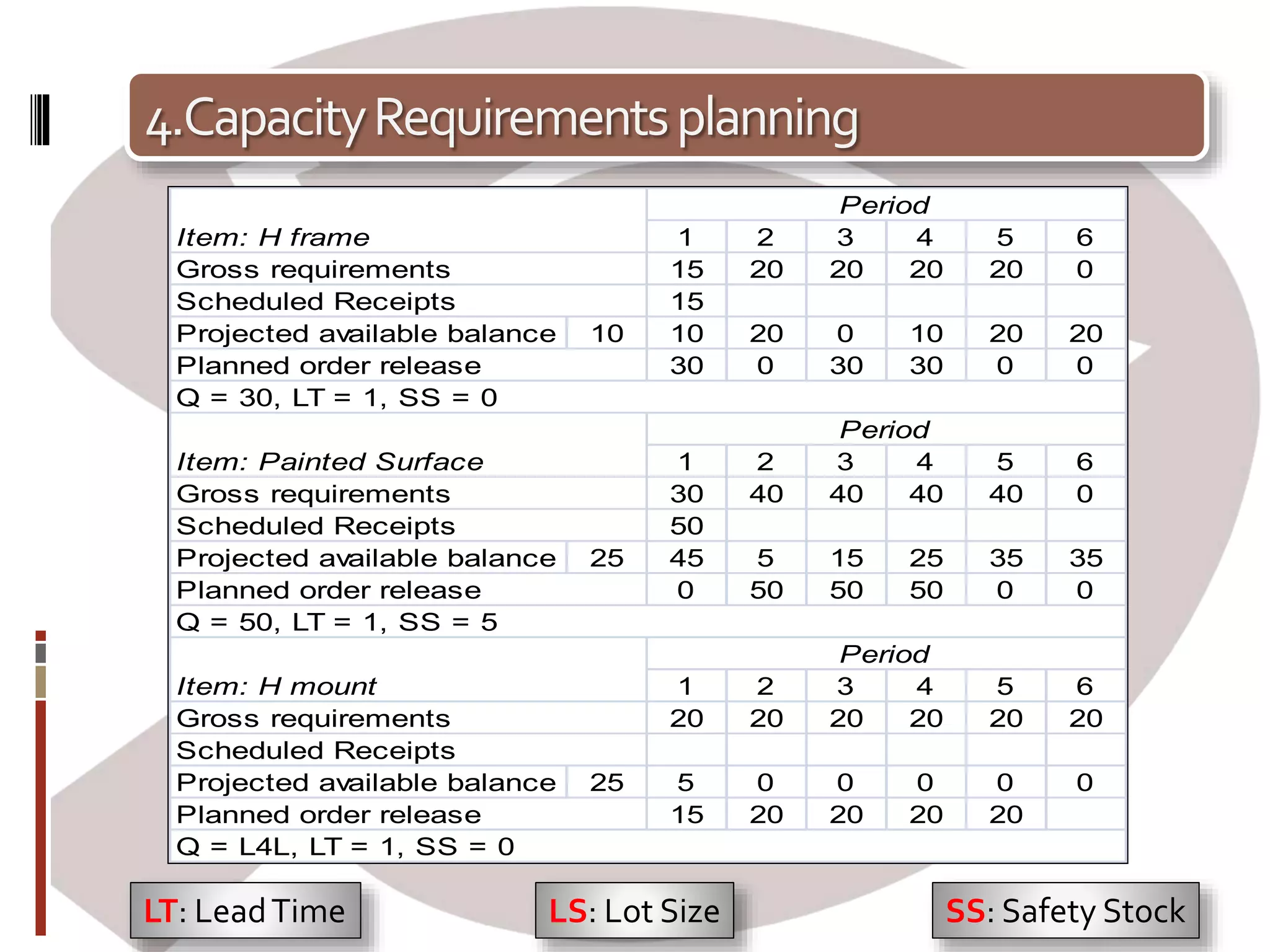

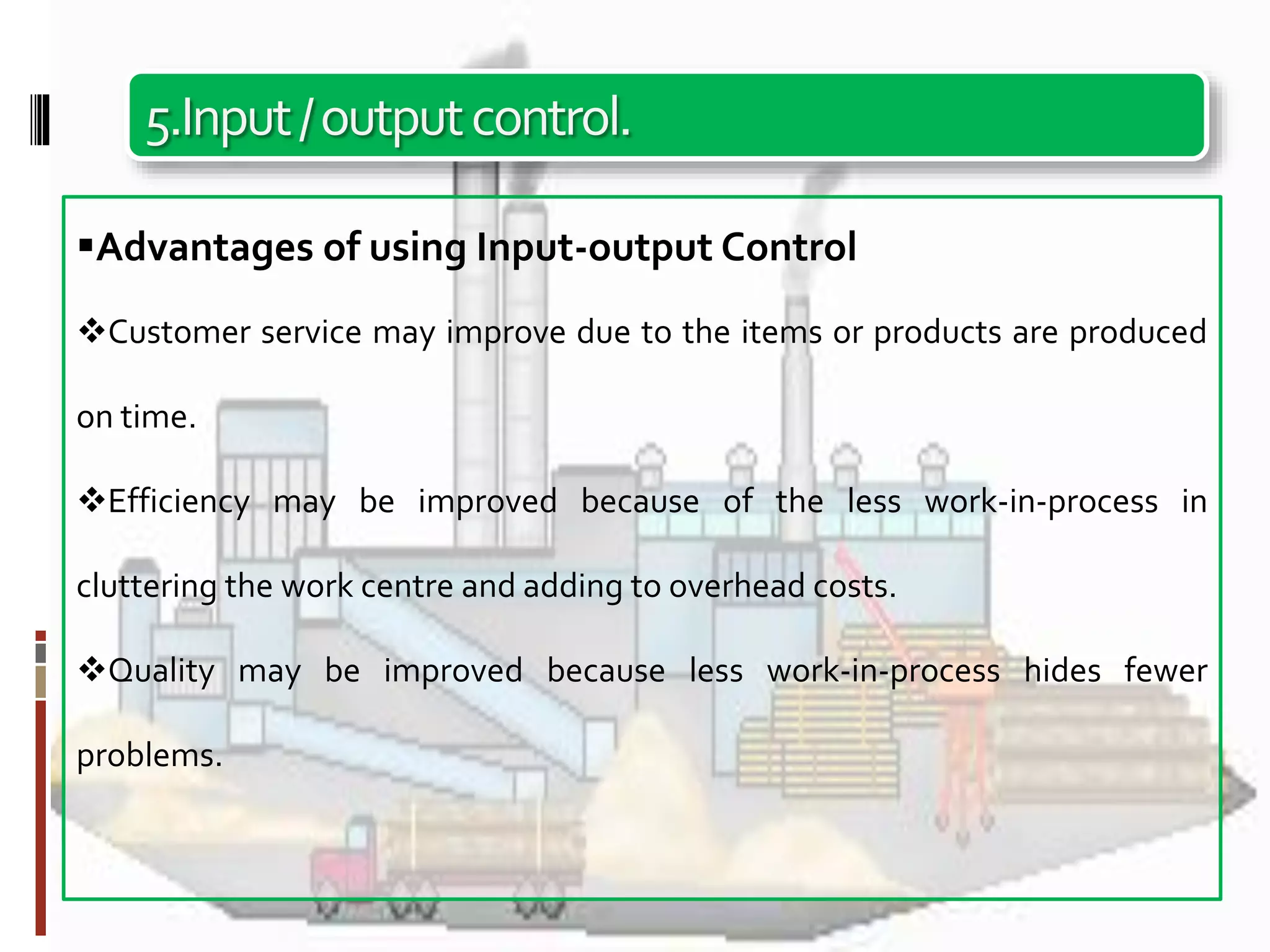

![1.CapacityPlanningInMPCSystem

From Hierarchy of Capacity Planning figure there

are relationship between MPC framework and

various capacity planning modules (five modules

range [long range –day to day] ):

o Vertical relationship among the capacity

planning modules

o Horizontal relationship with the material

planning modules of the MPC system .](https://image.slidesharecdn.com/manufacturingplanningandcontrolsystems-140331165937-phpapp02/75/Manufacturing-planning-and-control-systems-32-2048.jpg)