The document discusses manufacturing planning and control systems (MPC) and master production scheduling (MPS). Some key points:

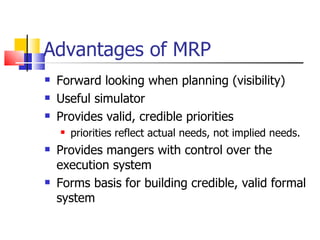

- MPC systems help formulate plans to meet business objectives and identify resource gaps. They facilitate feedback across suppliers and scheduling.

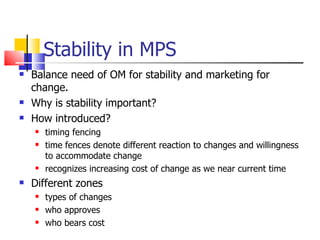

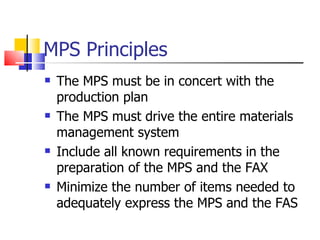

- An MPS is a time-phased statement of how resources will be used to meet production commitments over the planning horizon. It tends to have a short time horizon and show details like bills of materials.

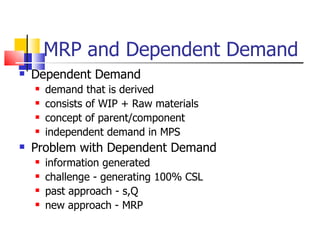

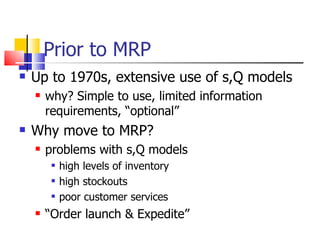

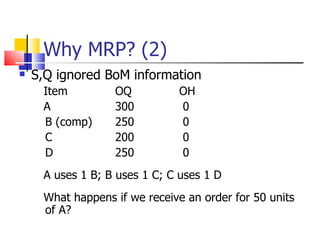

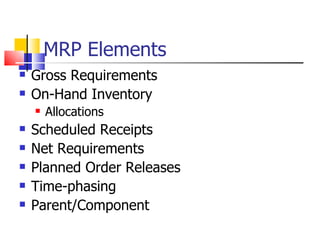

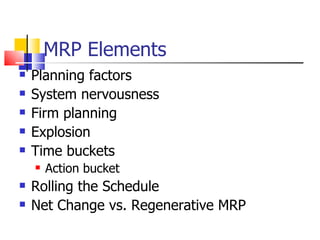

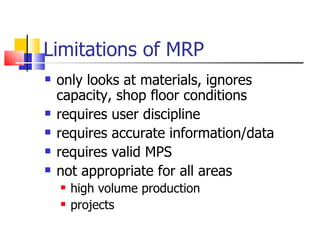

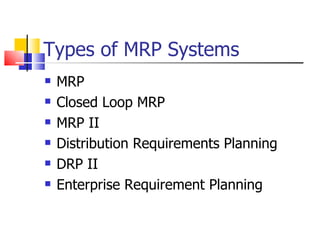

- MRP was developed to address limitations of traditional inventory models like economic order quantities. It incorporates bill of material information and dependent demand to improve inventory accuracy and reduce stockouts.