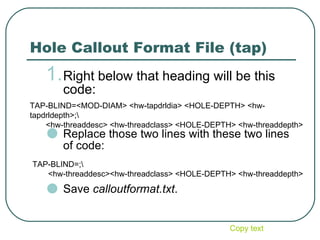

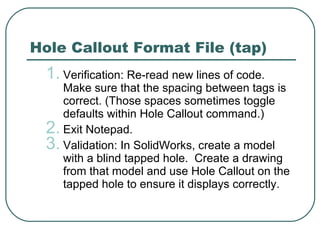

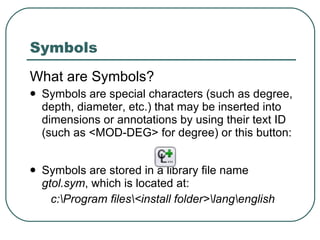

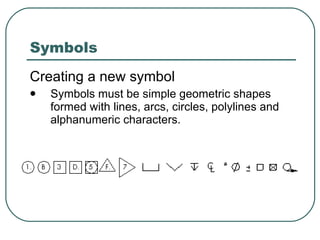

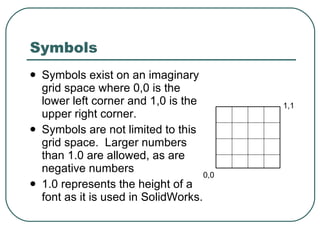

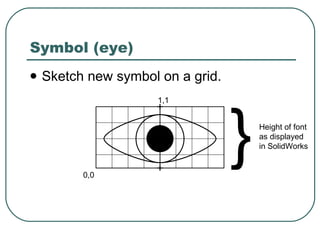

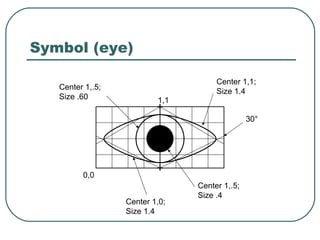

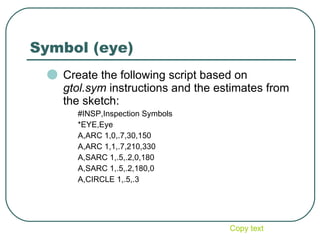

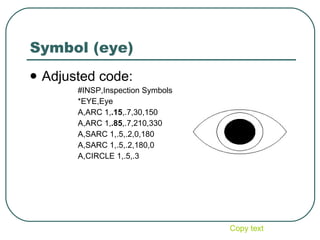

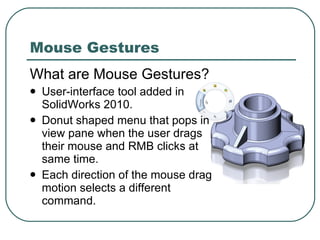

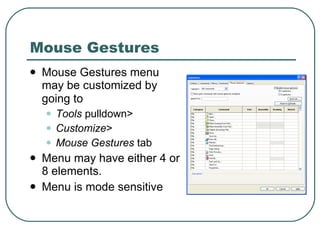

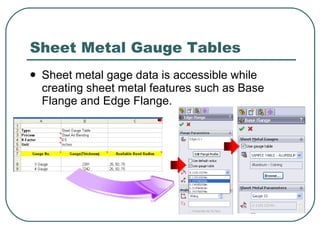

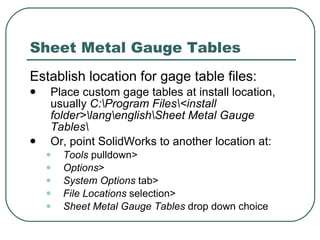

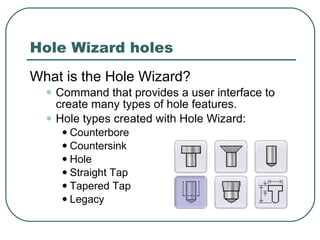

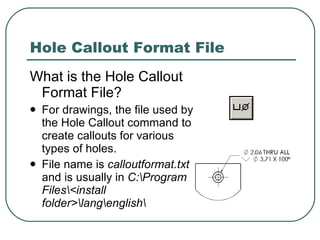

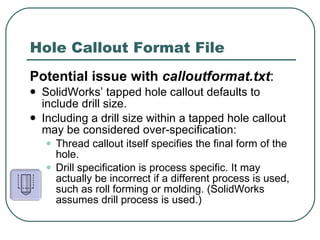

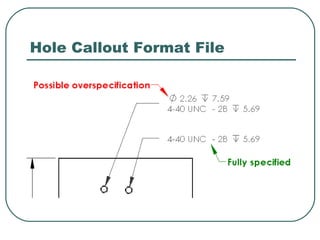

The document provides an overview of advanced customization techniques in SolidWorks, including customizing tags, mouse gestures, shortcut bars, sheet metal gauge tables, the hole wizard, hole callouts, symbols, and more. Specific examples are given around modifying hole callouts to remove drill size from tapped holes, creating a custom sheet metal gauge table, and adding a new symbol for visual inspection. The presentation aims to expose attendees to customizable areas in SolidWorks and provide instructions to allow users to explore these customizations on their own.

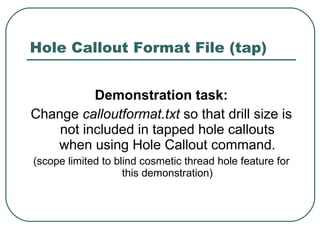

![Locate calloutformat.tx t and make a backup copy. Then open calloutformat.txt with Windows Notepad or similar. Search for “[ANSI Inch]” and then the heading “TAPPED HOLES”. Hole Callout Format File (tap)](https://image.slidesharecdn.com/solidworksadvancedcustomizationtechniques-12802816333643-phpapp02/85/SolidWorks-Advanced-Customization-Techniques-40-320.jpg)