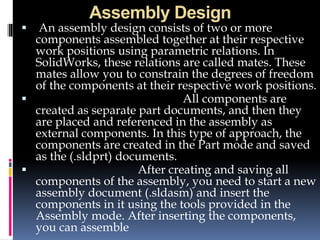

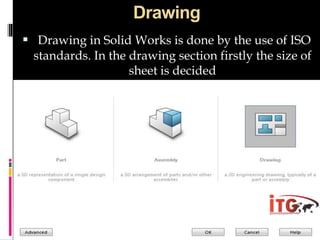

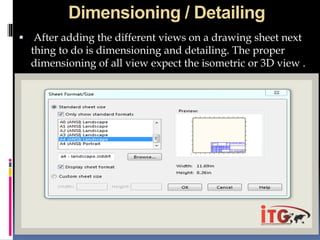

SolidWorks is a computer-aided design and engineering software produced by Dassault Systèmes, initially founded by Jon Hirschtick in 1993. It facilitates 3D modeling, part design, assembly design, and drawing creation using parametric relations and ISO standards. The software is widely utilized by over 2 million engineers across various industries, providing tools for efficient design and documentation.

![Introduction

The Solid Works software is a solid modeling computer aided

design (CAD) and computer aided engineering (CAE) software

program that runs on Microsoft Windows. The SolidWorks is

produced by the Dassault Systems— a subsidiary of Dassault

Systèmes. Solid Works is currently used by over 2 million

engineers and designers at more than 165,000 .

SOLIDWORKS Corporation was founded in

December 1993 by Massachusetts Institute of Technology

graduate Jon Hirschtick; Hirschtick used $1 million he had made

while a member of the MIT Blackjack Team to set up the

company. Initially based in Waltham, Massachusetts, USA,

Hirschtick recruited a team of engineers with the goal of

building 3D CAD software that was easy-to-use, affordable, and

available on the Windows desktop. Operating later from

Concord, Massachusetts, SOLIDWORKS released its first

product SolidWorks 95, in 1995.[5][6] In 1997 Dassault, best

known for its CATIA CAD software, acquired SolidWorks for

$310 million in stock.](https://image.slidesharecdn.com/solidworks-161214105047/85/Infotechnogen-Solid-works-3-320.jpg)