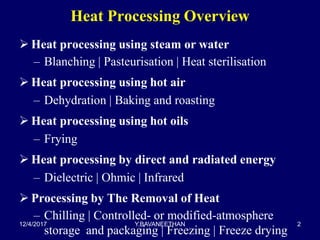

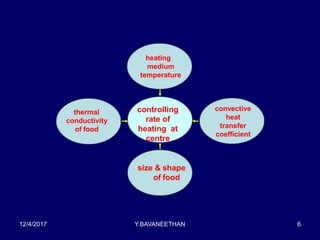

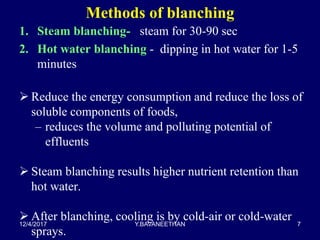

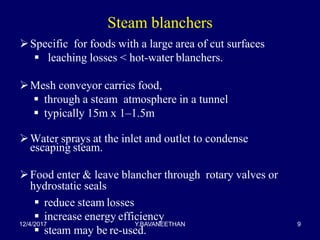

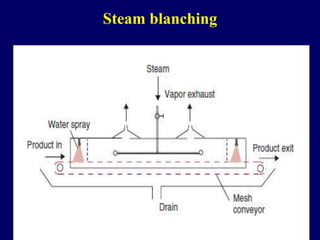

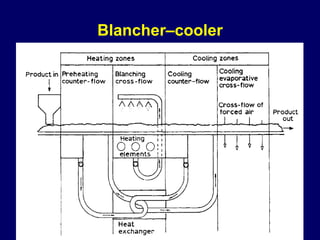

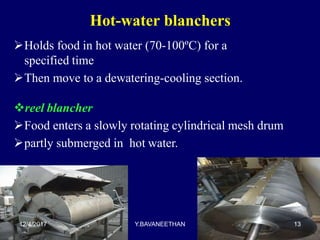

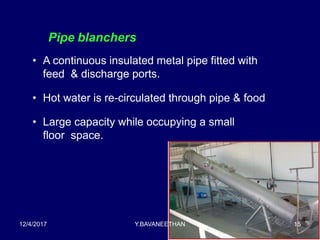

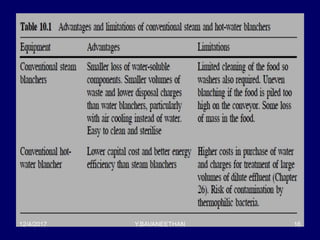

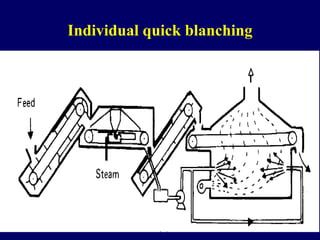

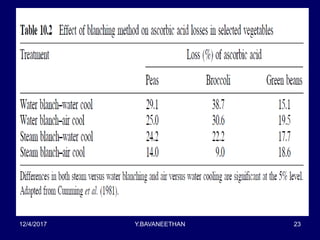

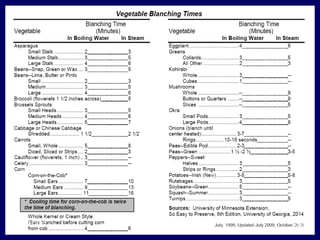

The document discusses heat processing methods used in food technology, focusing on blanching. It defines blanching as a heat treatment used to inactivate enzymes in fruits and vegetables prior to further processing. The document describes different blanching methods including steam blanching and hot water blanching. It also discusses newer techniques such as individual quick blanching that aim to minimize nutrient losses and improve process efficiency.