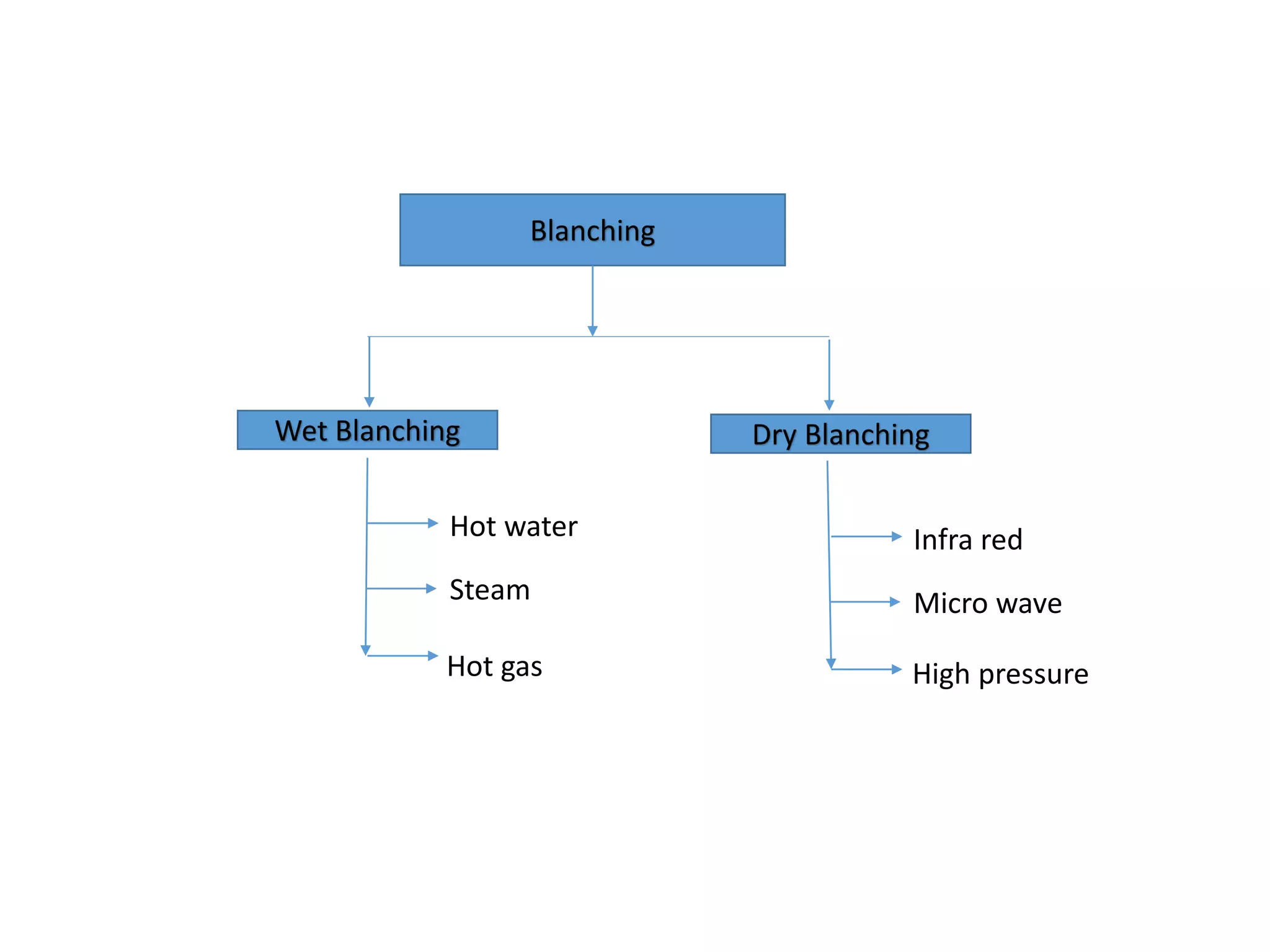

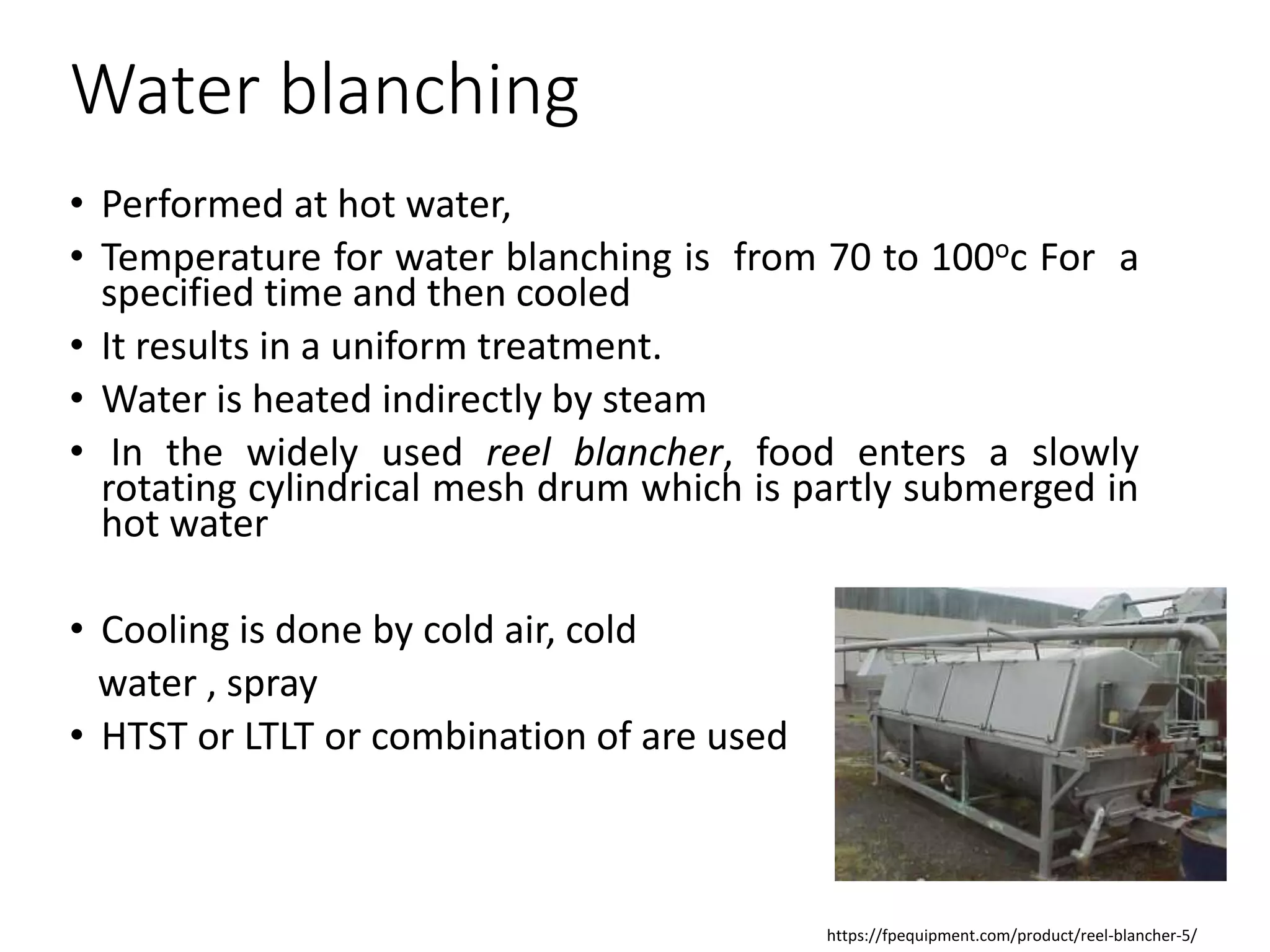

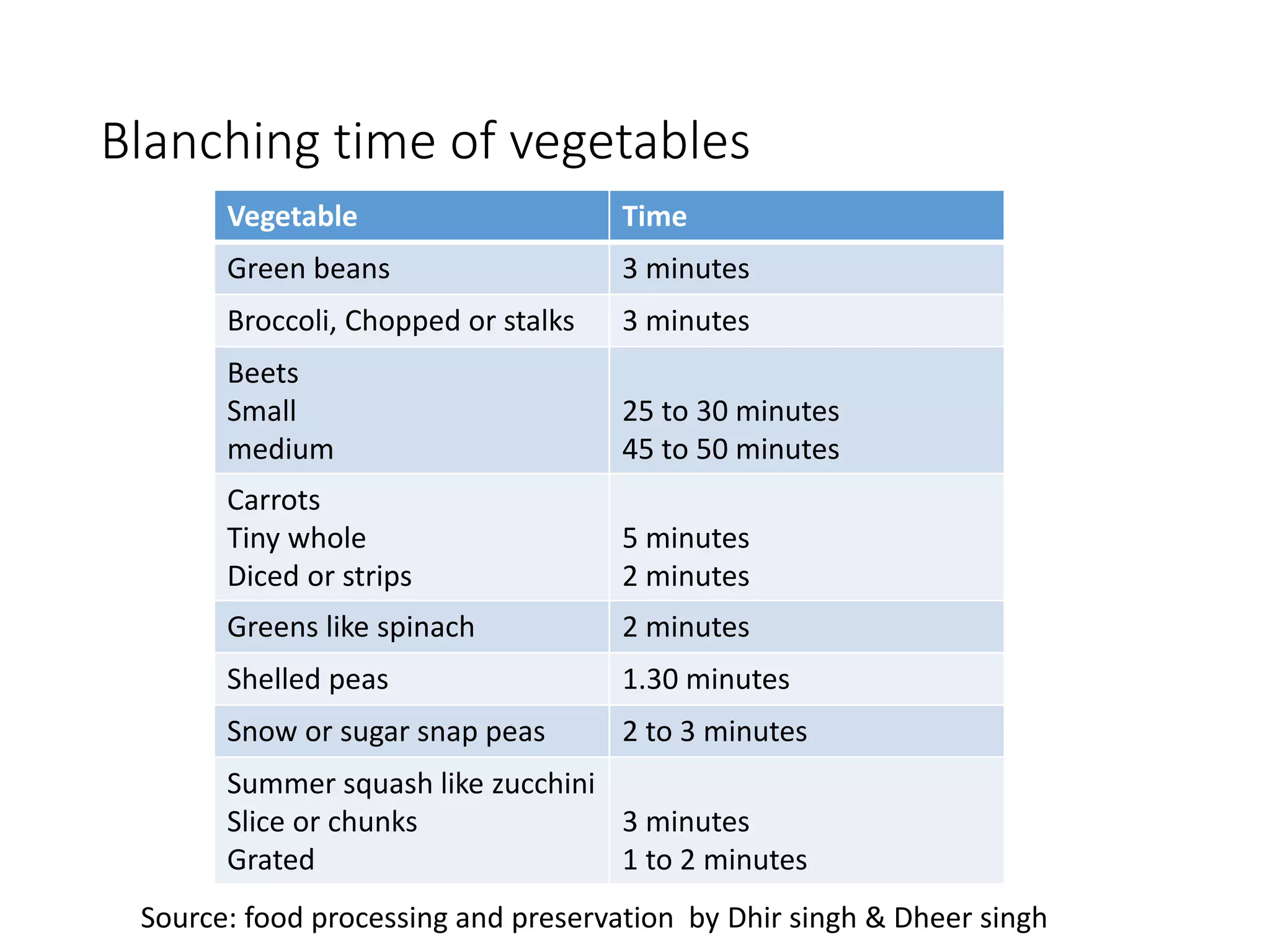

Blanching is a heat treatment used prior to freezing, canning, or drying fruits and vegetables. It involves scalding produce in boiling water or steam to inactivate enzymes and microorganisms. Blanching helps preserve color, flavor, texture and nutrients. Key factors like product type, size, temperature, and heating method influence blanching time. It is a critical pre-treatment step but not a method of preservation on its own. Modern blanching techniques include steam, hot water, microwave, infrared and high-pressure methods.