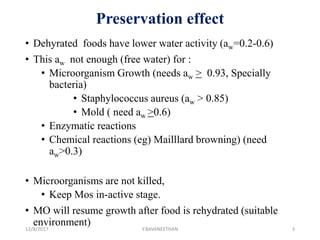

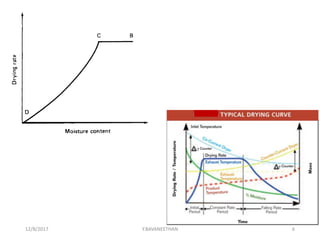

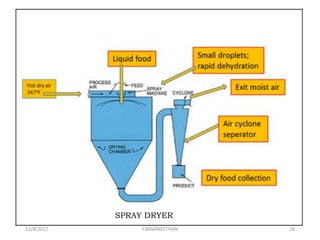

Dehydration is a method of food preservation that involves removing water from foods through the application of heat. This reduction in water content inhibits microbial growth and enzyme activity, extending the shelf life of foods. However, dehydration also causes deterioration in food quality attributes like texture, flavor, and nutrition. Various factors influence the dehydration process, and different equipment like cabinet dryers, tunnel dryers, and spray dryers are used depending on the type of food being dried.