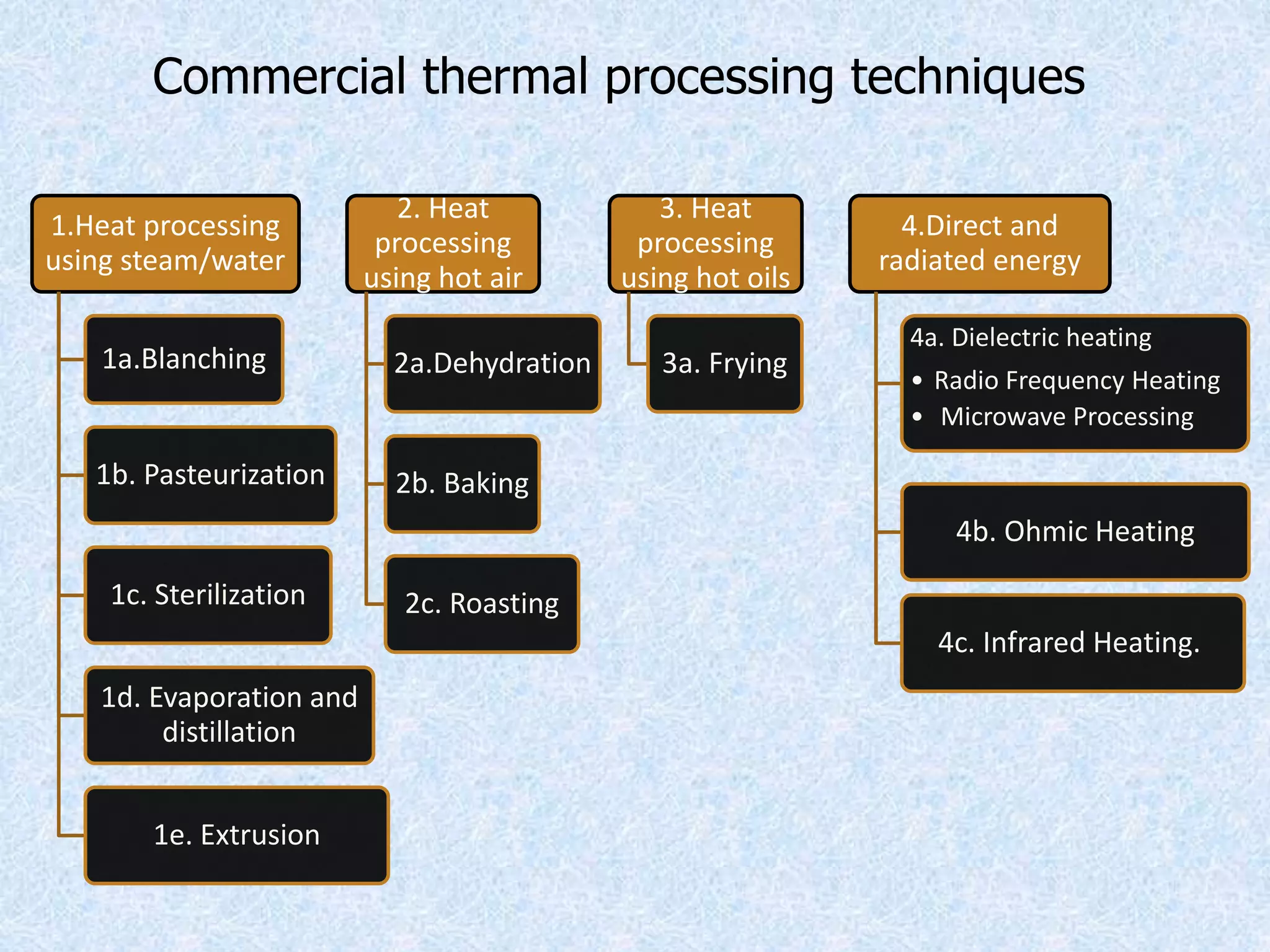

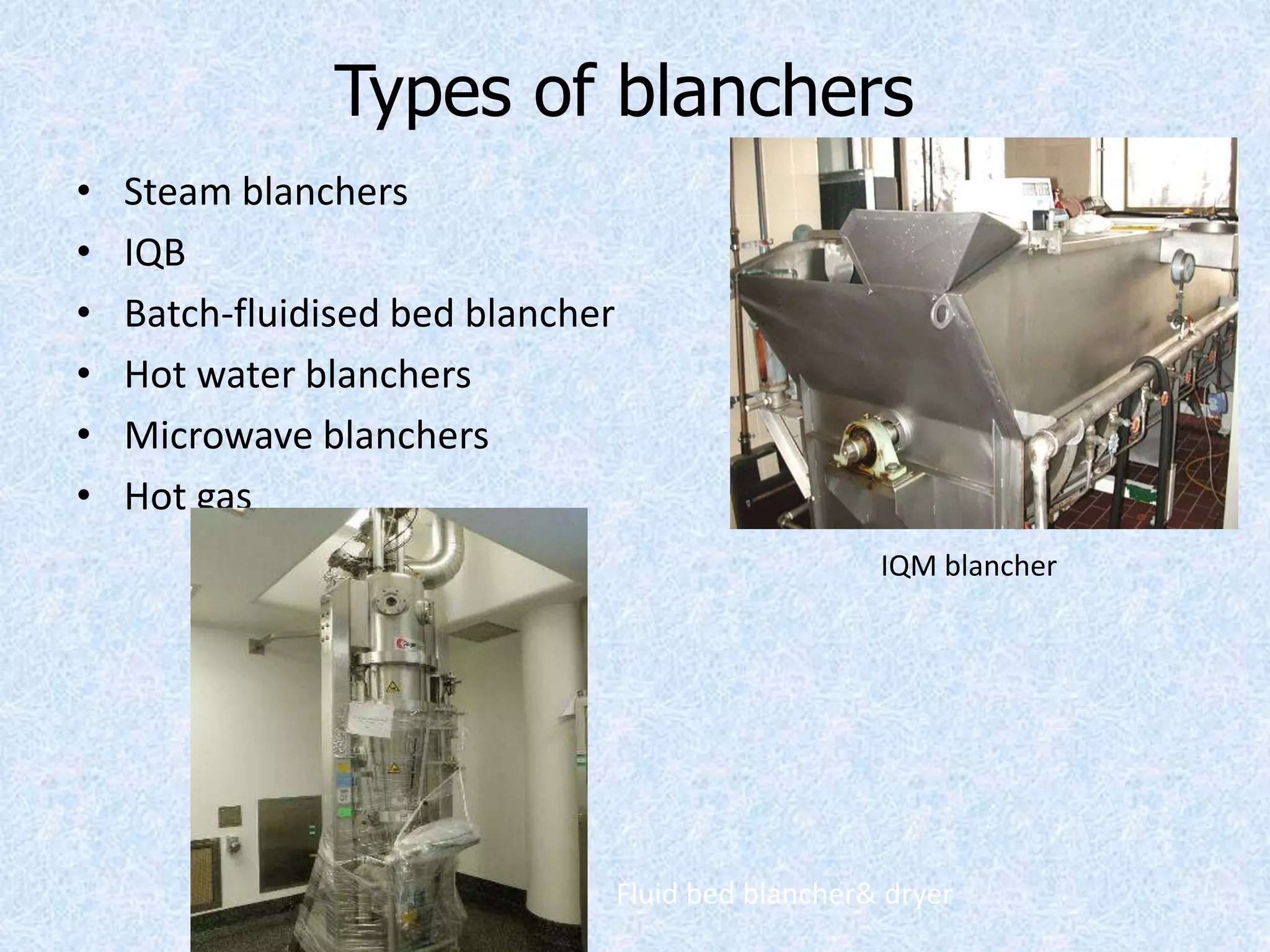

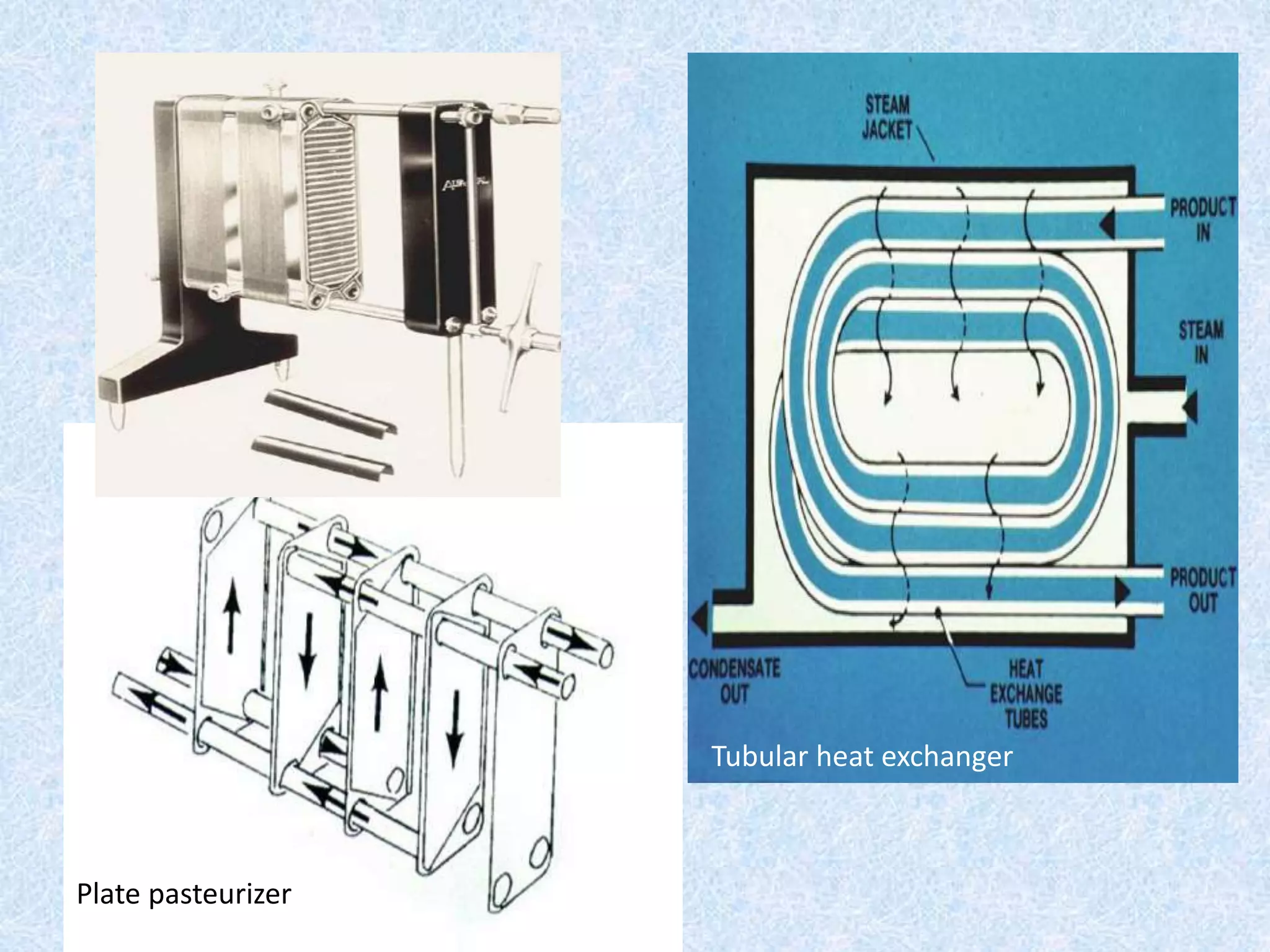

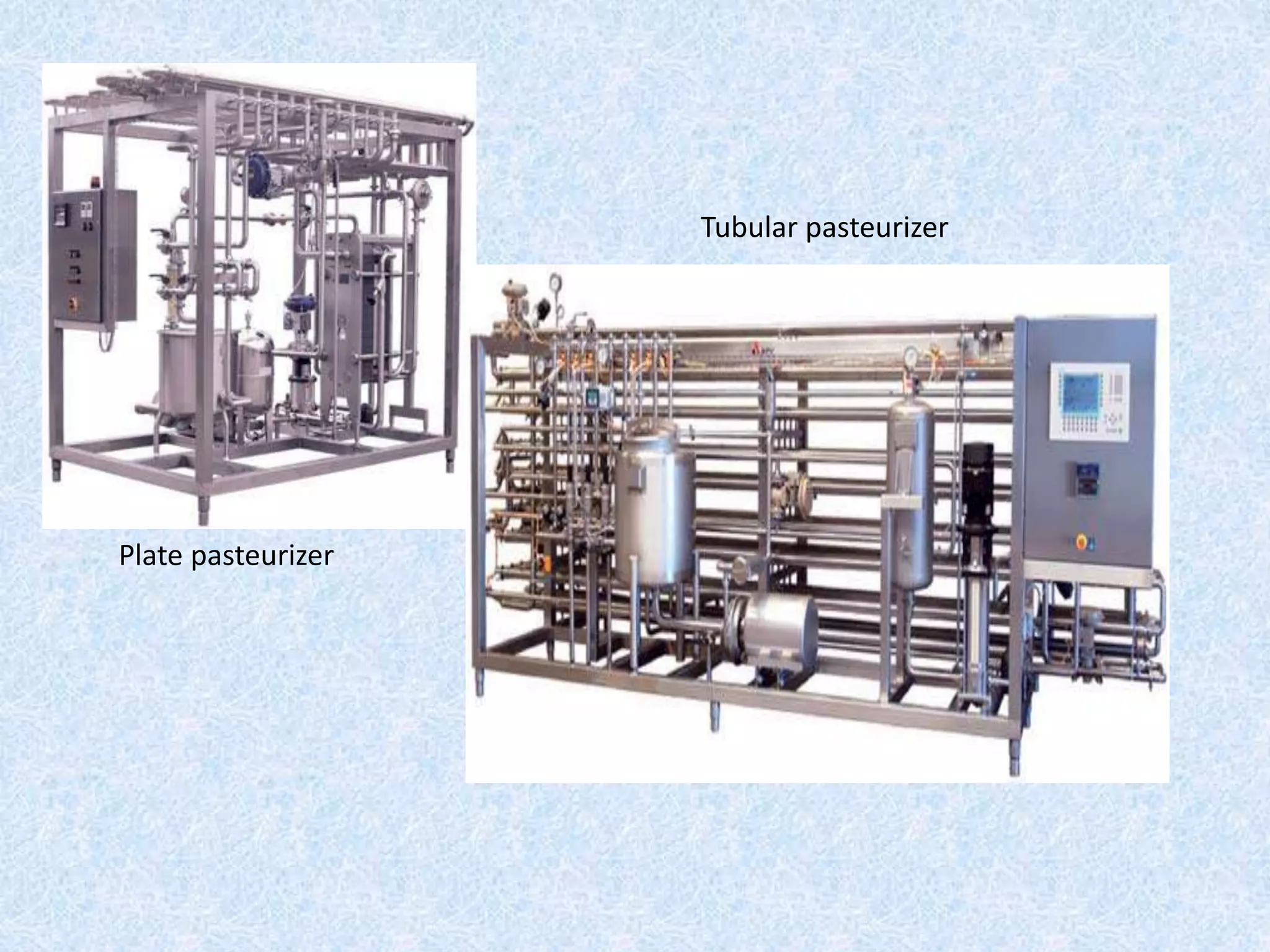

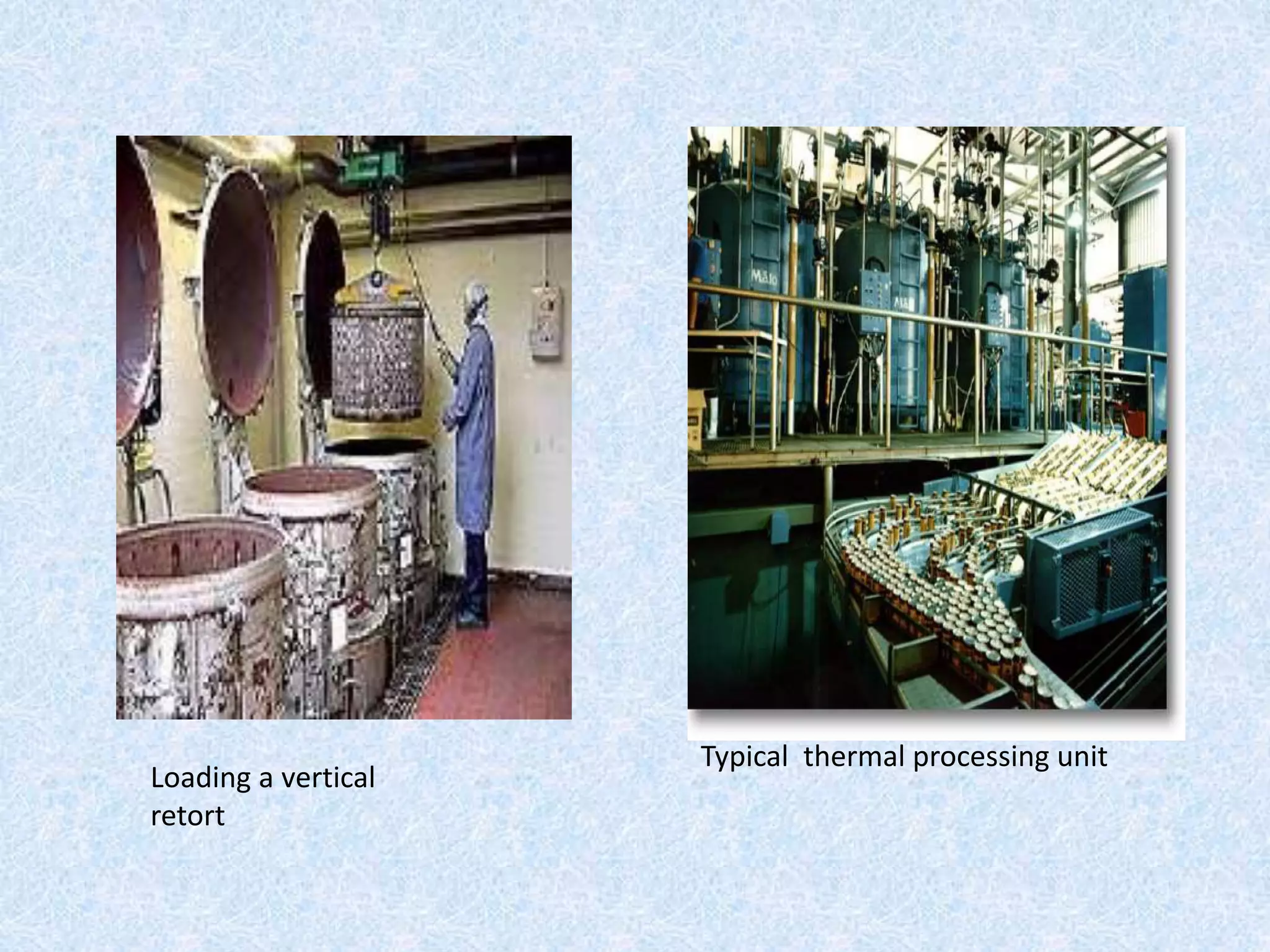

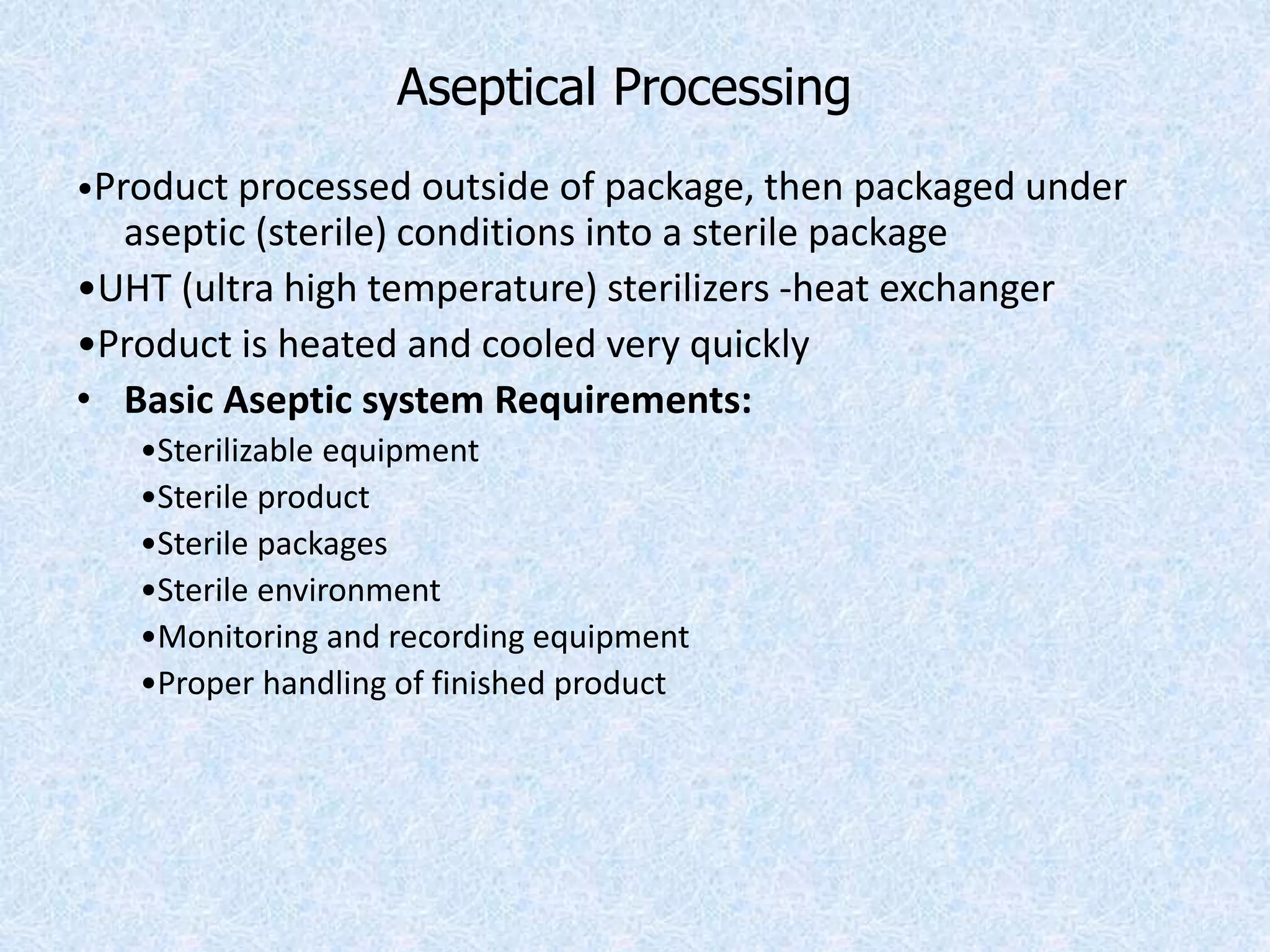

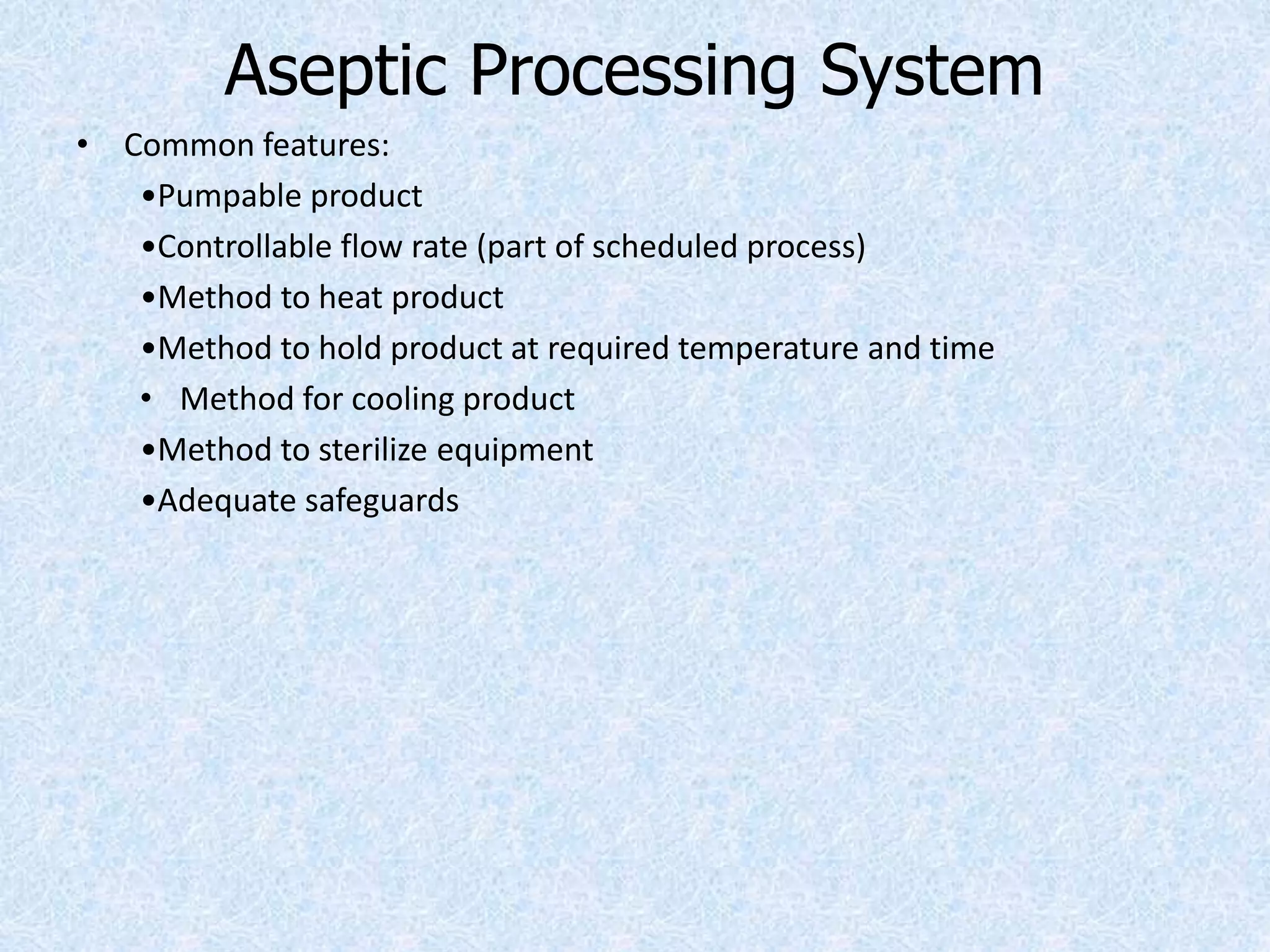

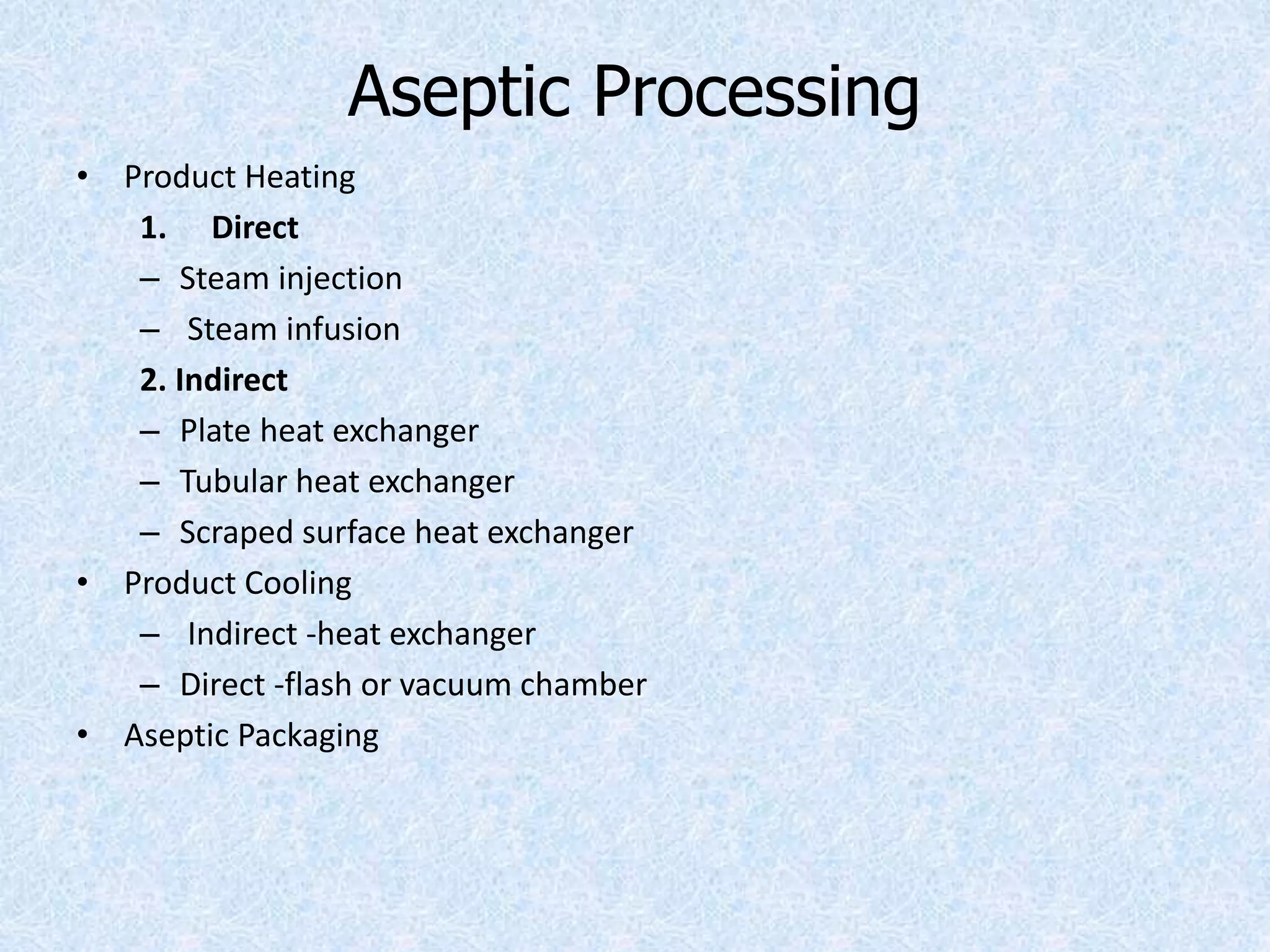

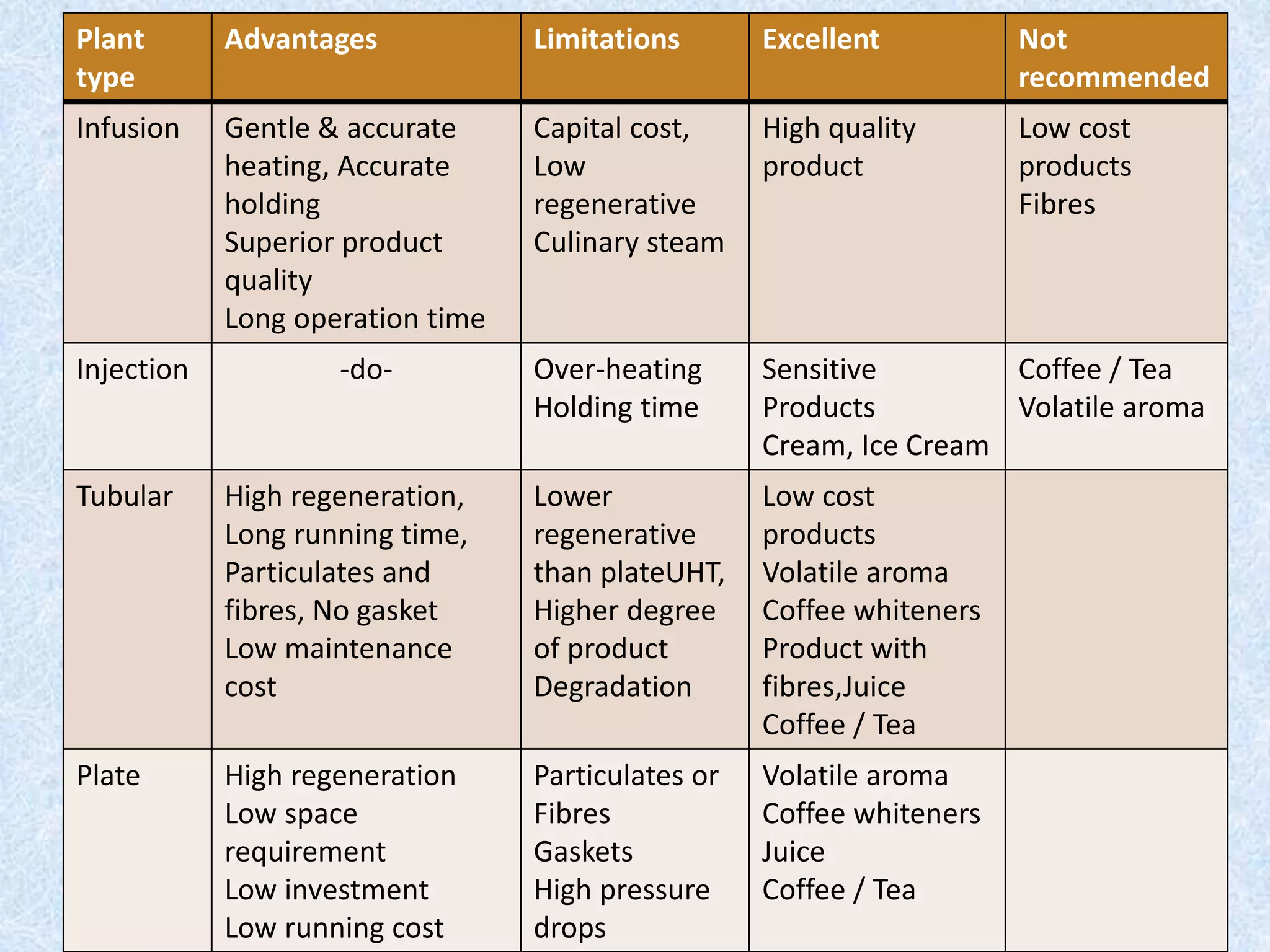

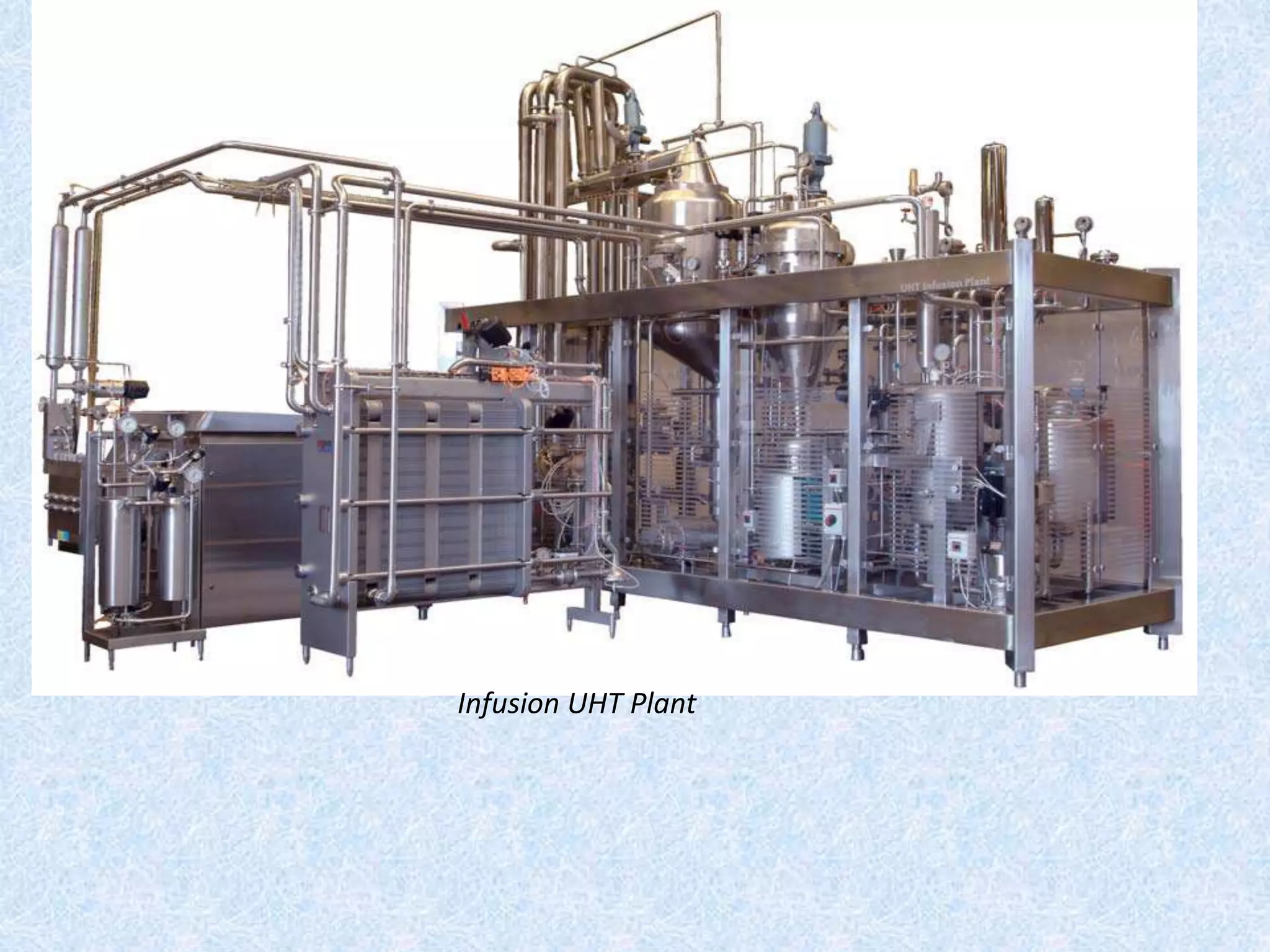

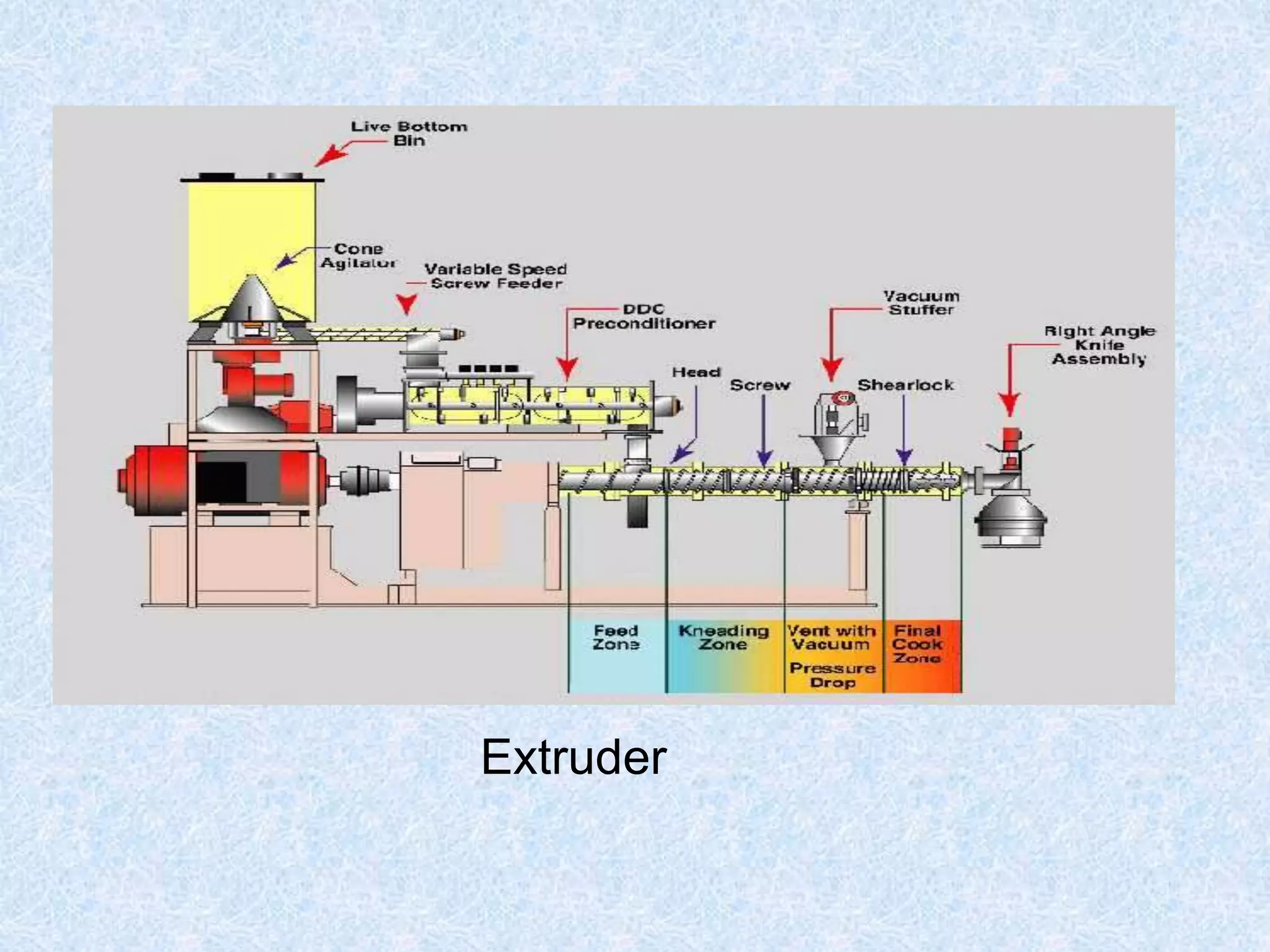

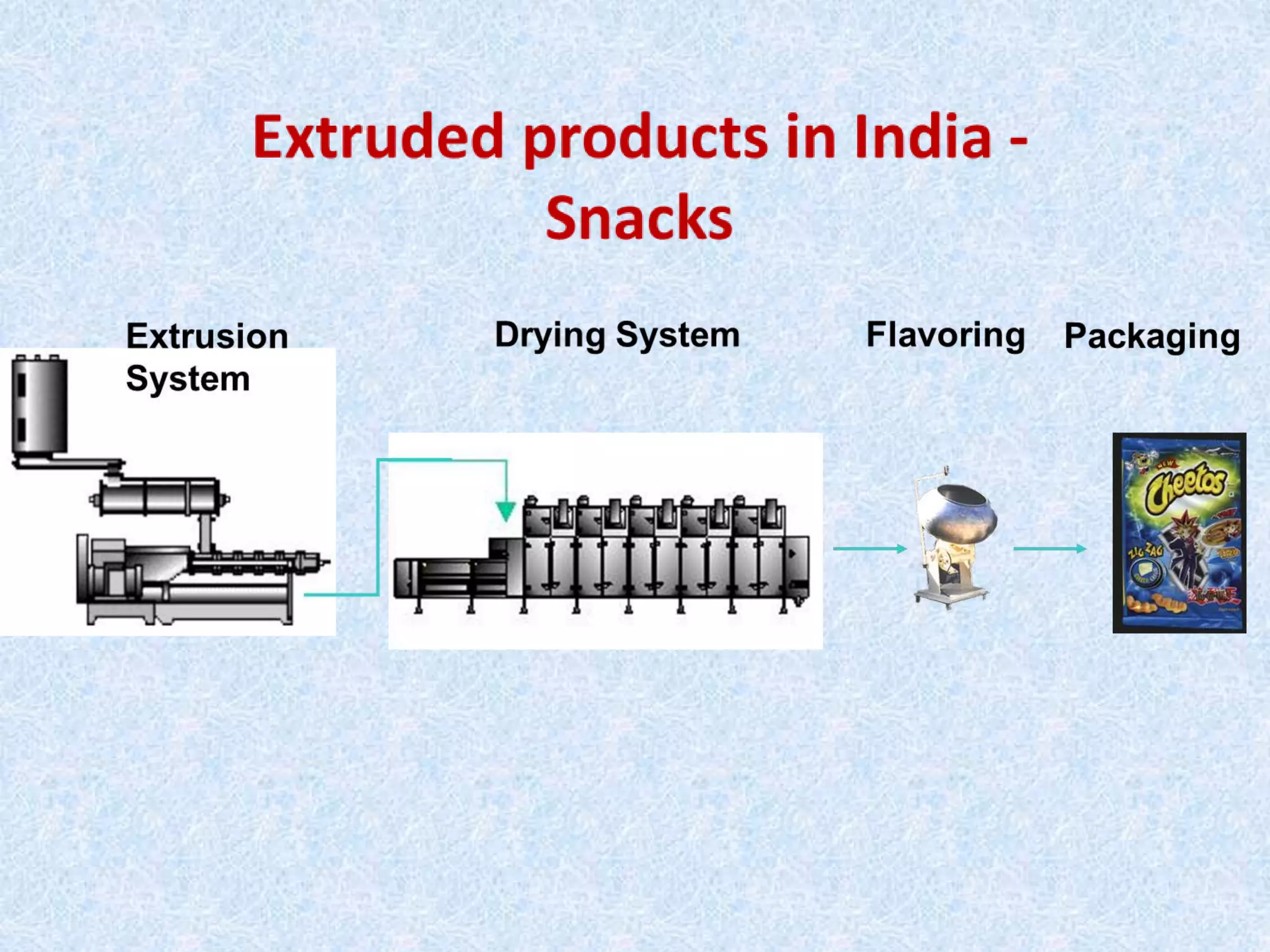

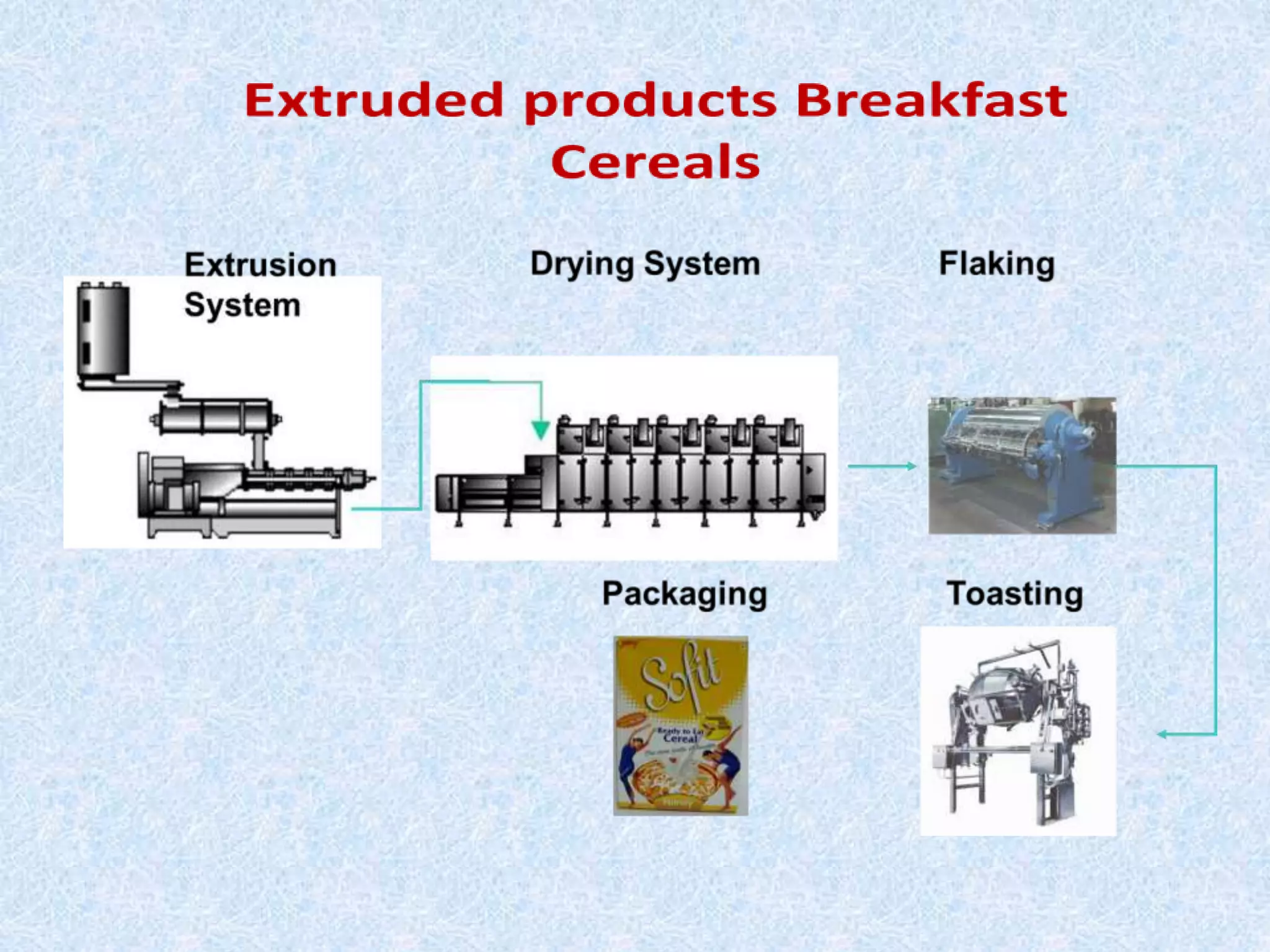

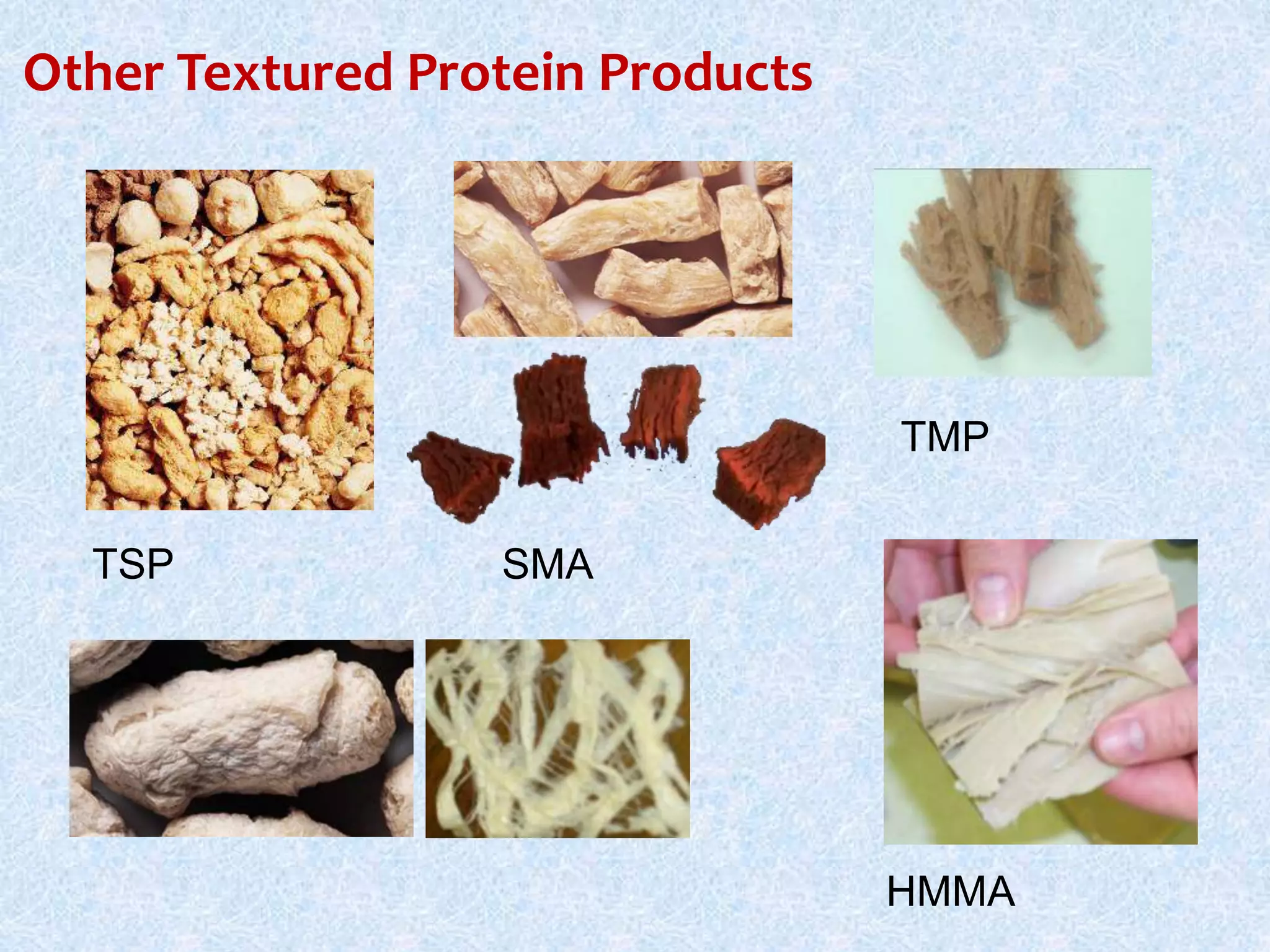

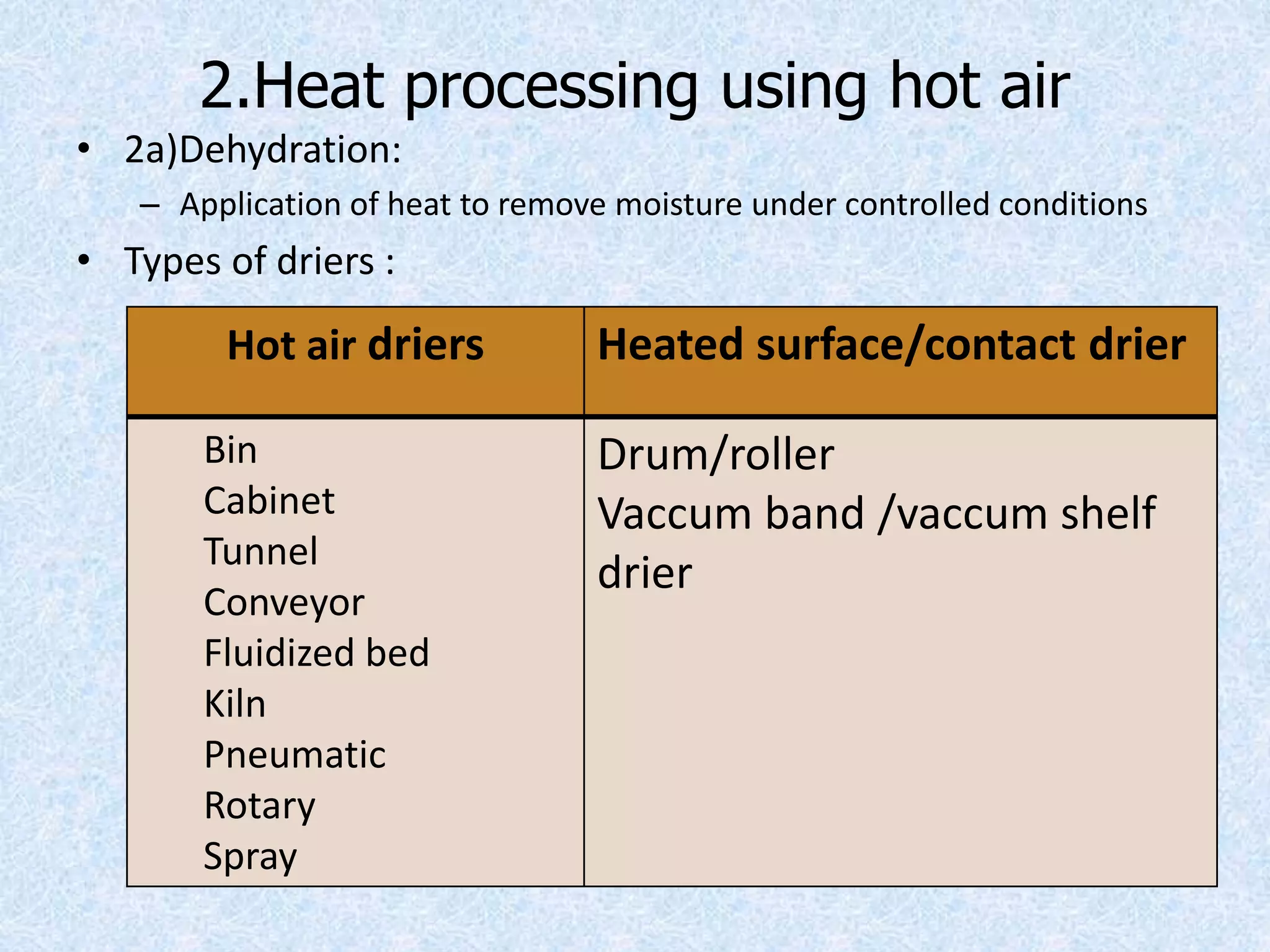

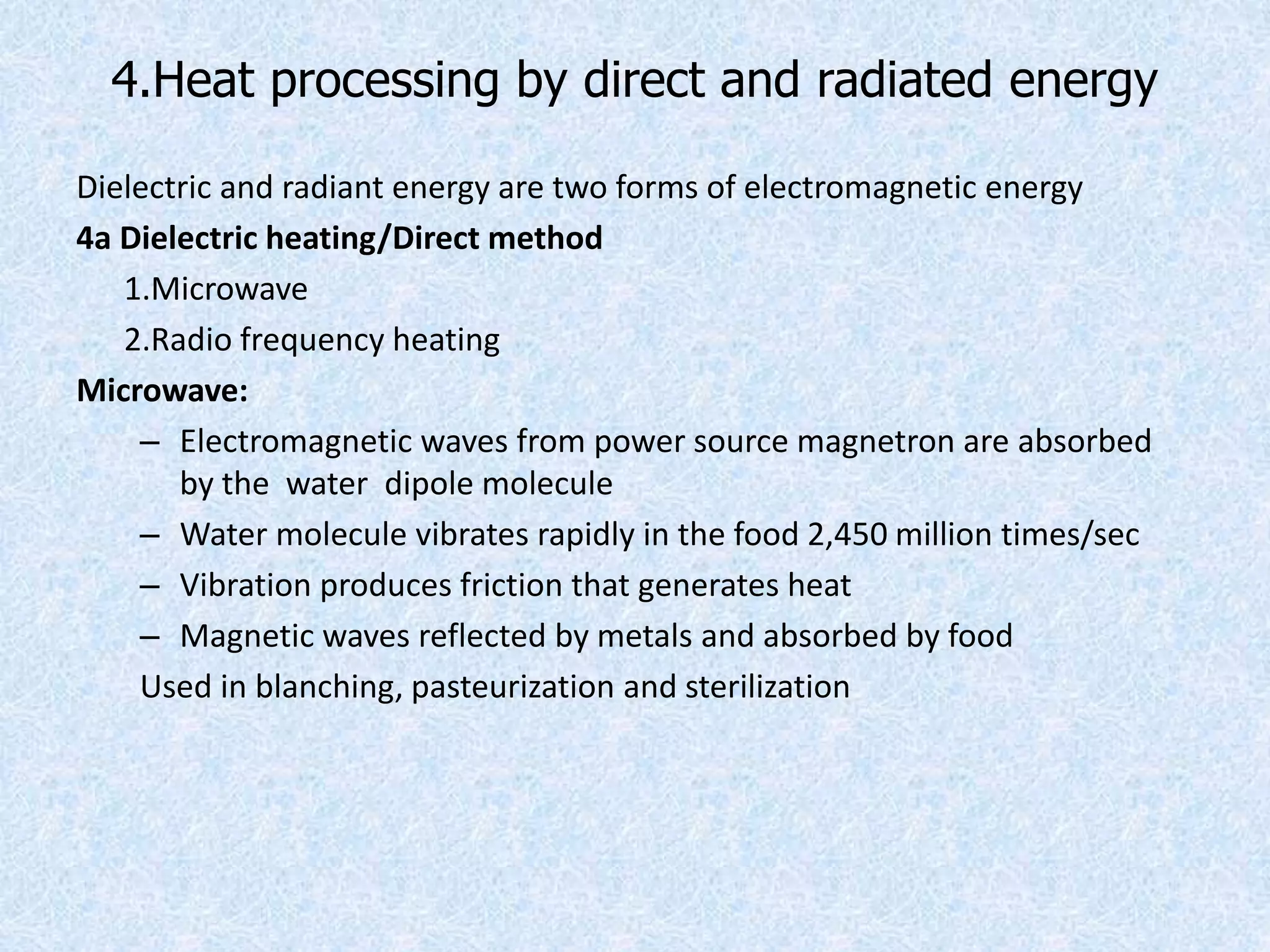

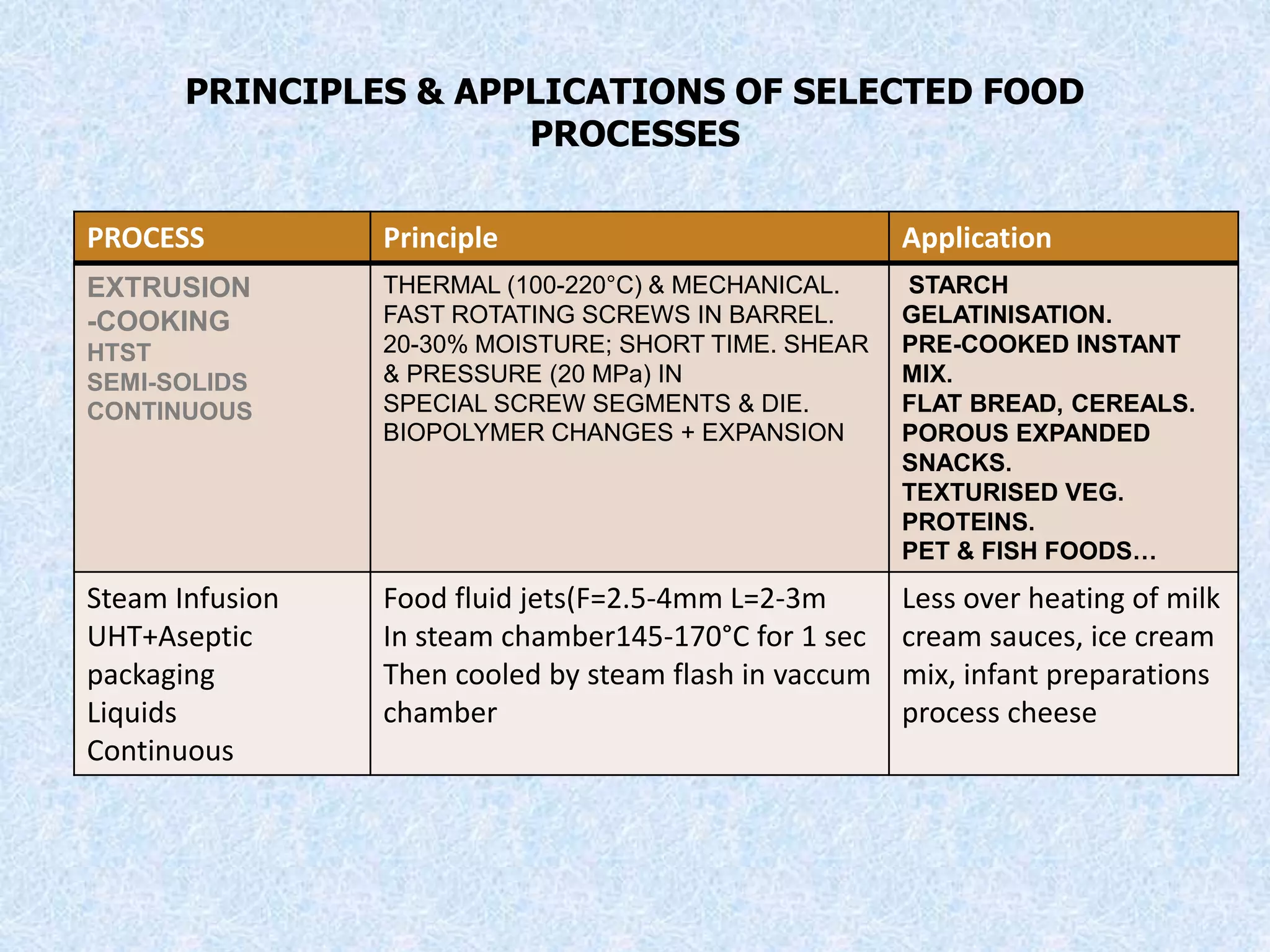

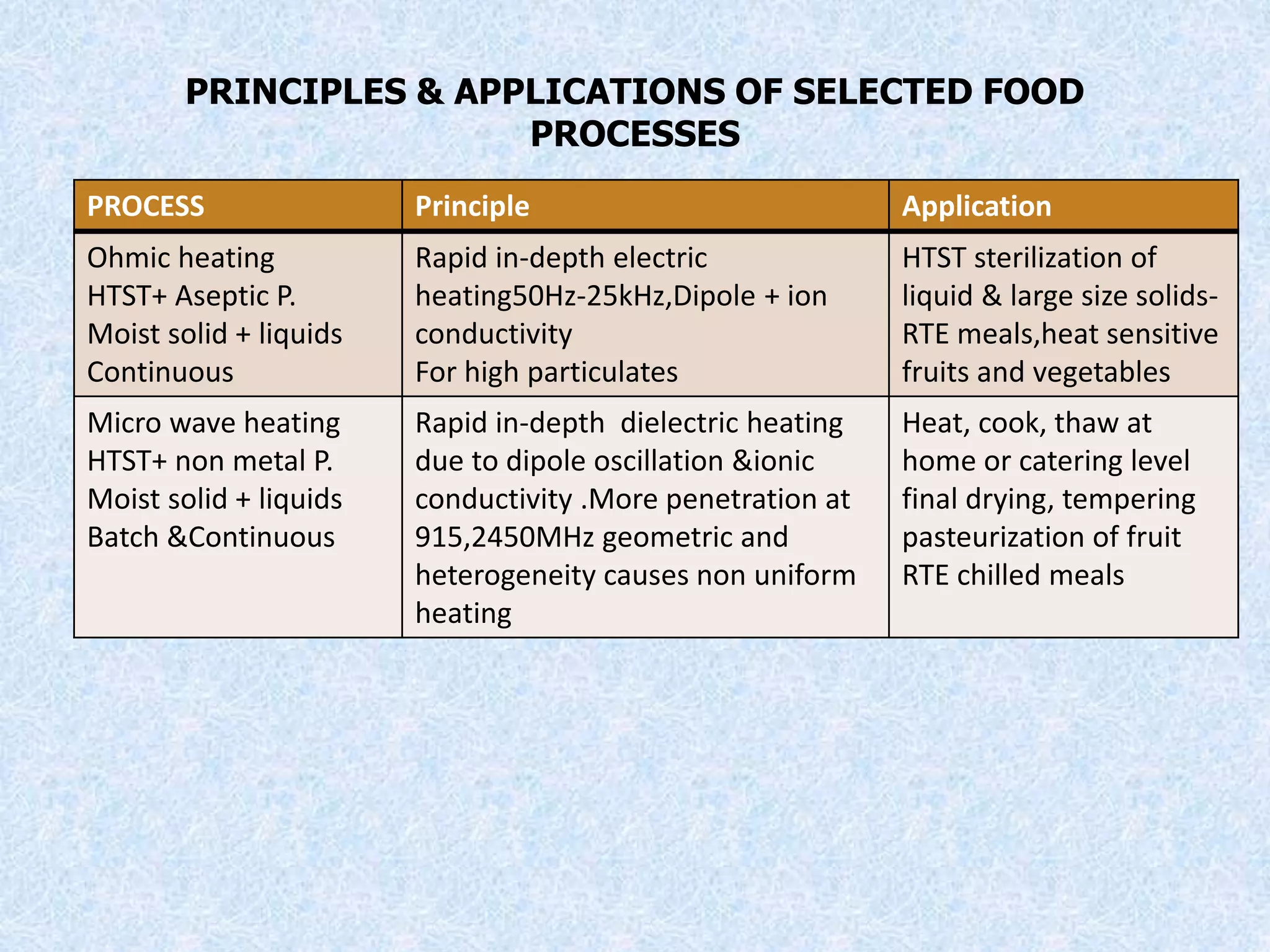

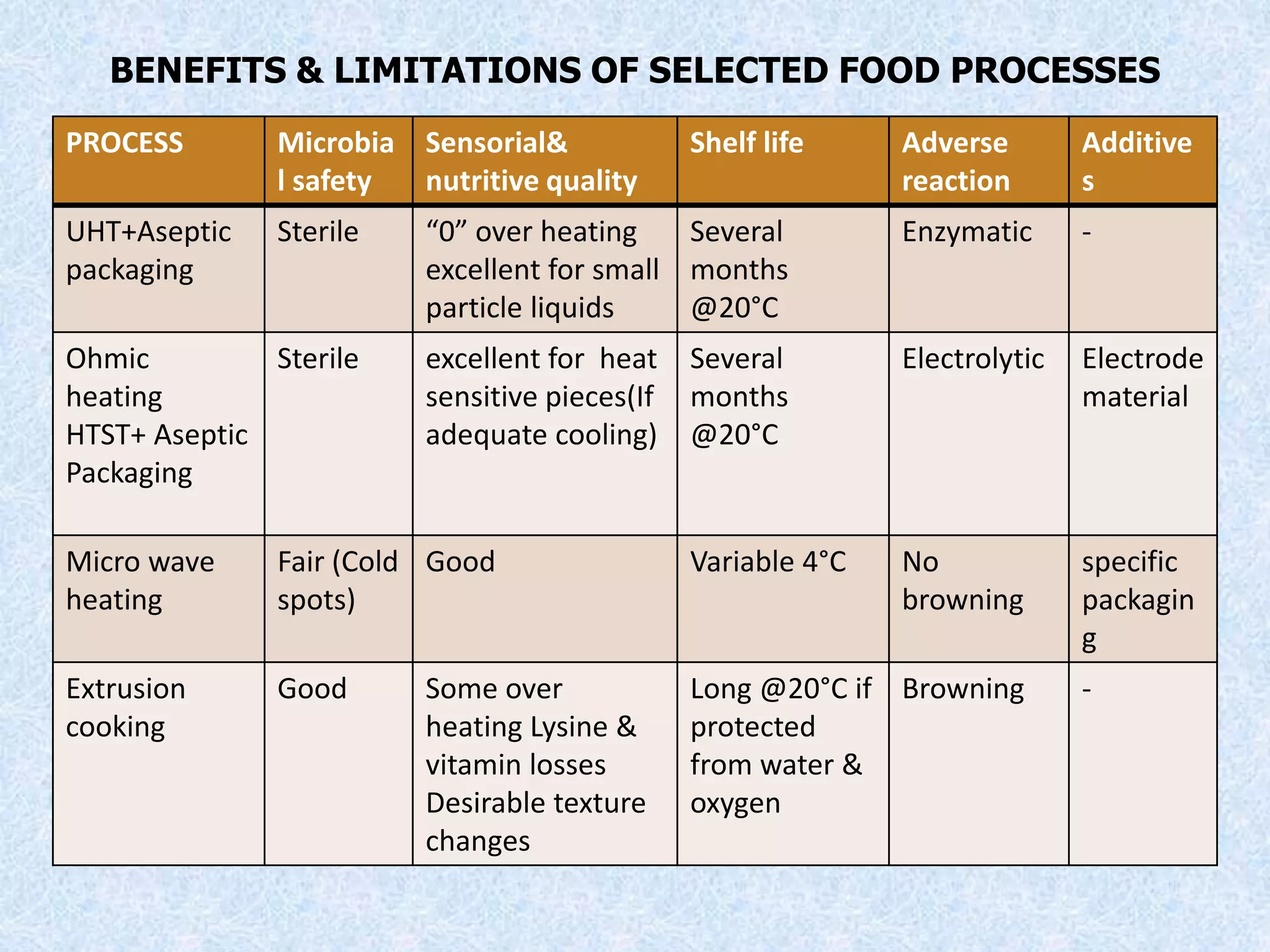

Thermal food processing technologies include various cooking and heat treatment methods like baking, boiling, frying, and more. These methods make food safer, more palatable, and in some cases help preserve it. Common thermal processing techniques discussed include blanching, pasteurization, sterilization, evaporation/concentration, extrusion, dehydration, baking/roasting, and frying. Newer methods like aseptic processing are also covered, which sterilize food outside the package before aseptically filling sterile containers. The document provides details on the principles, equipment used, advantages, and limitations of various thermal food processing technologies.