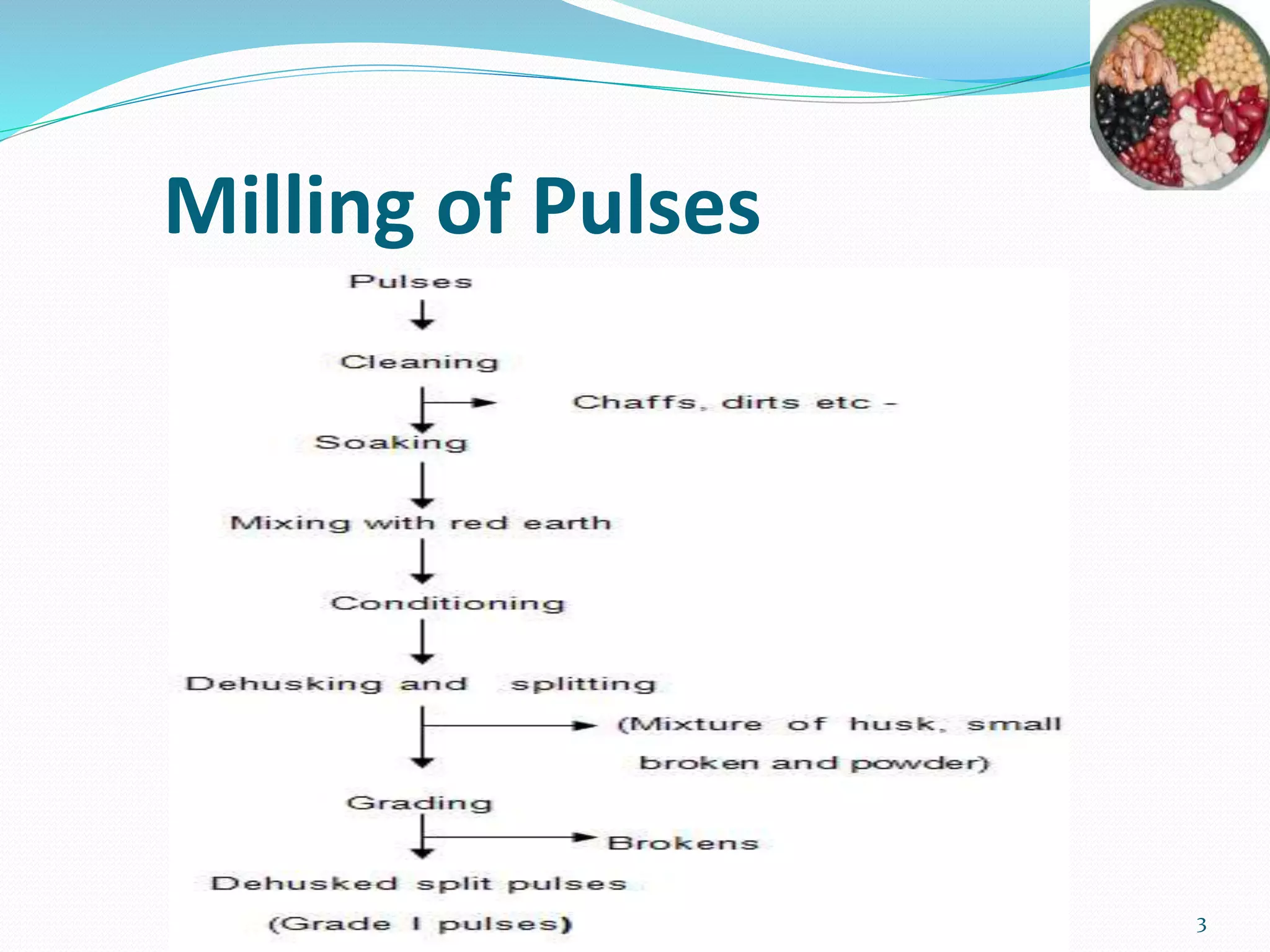

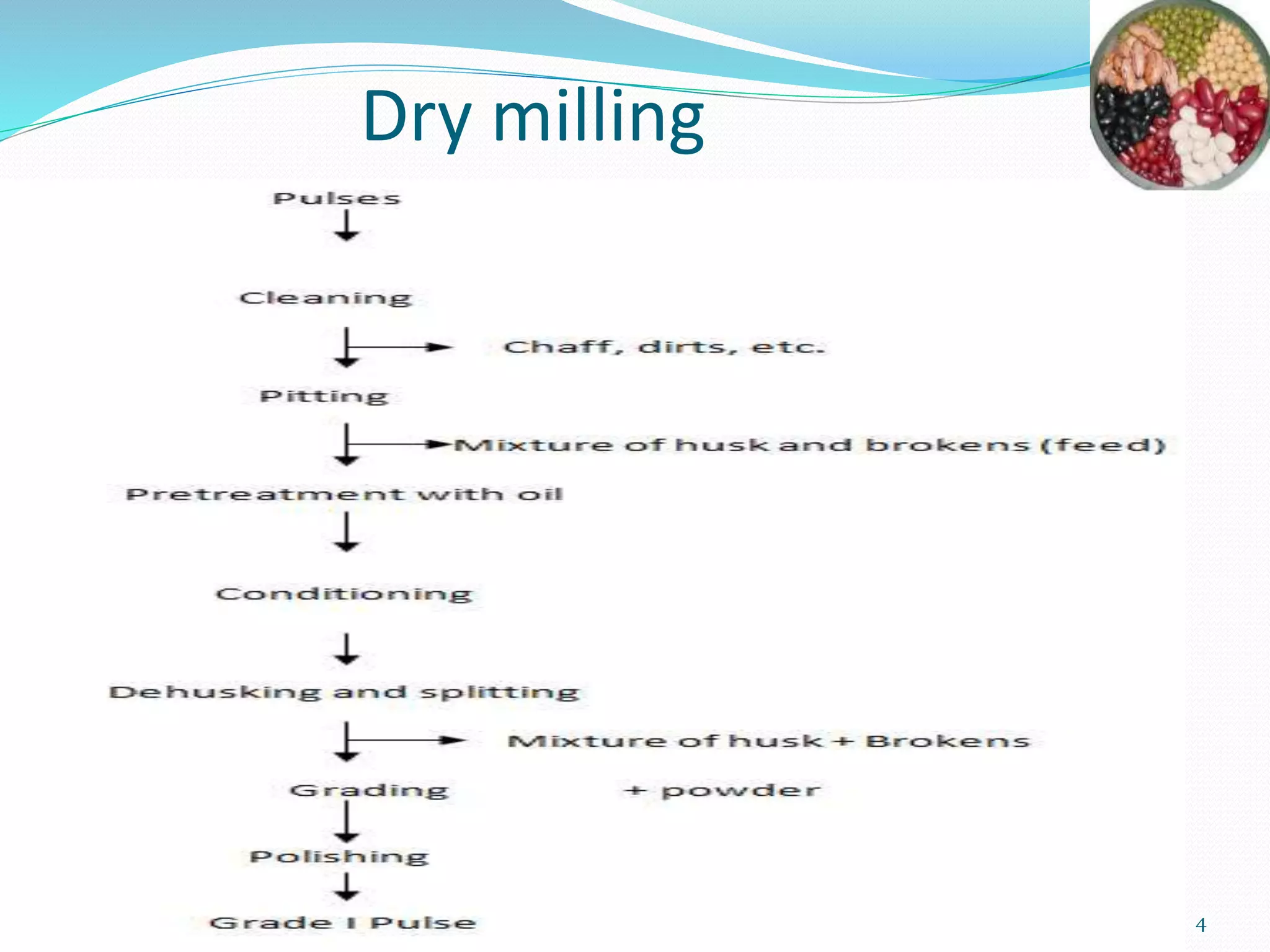

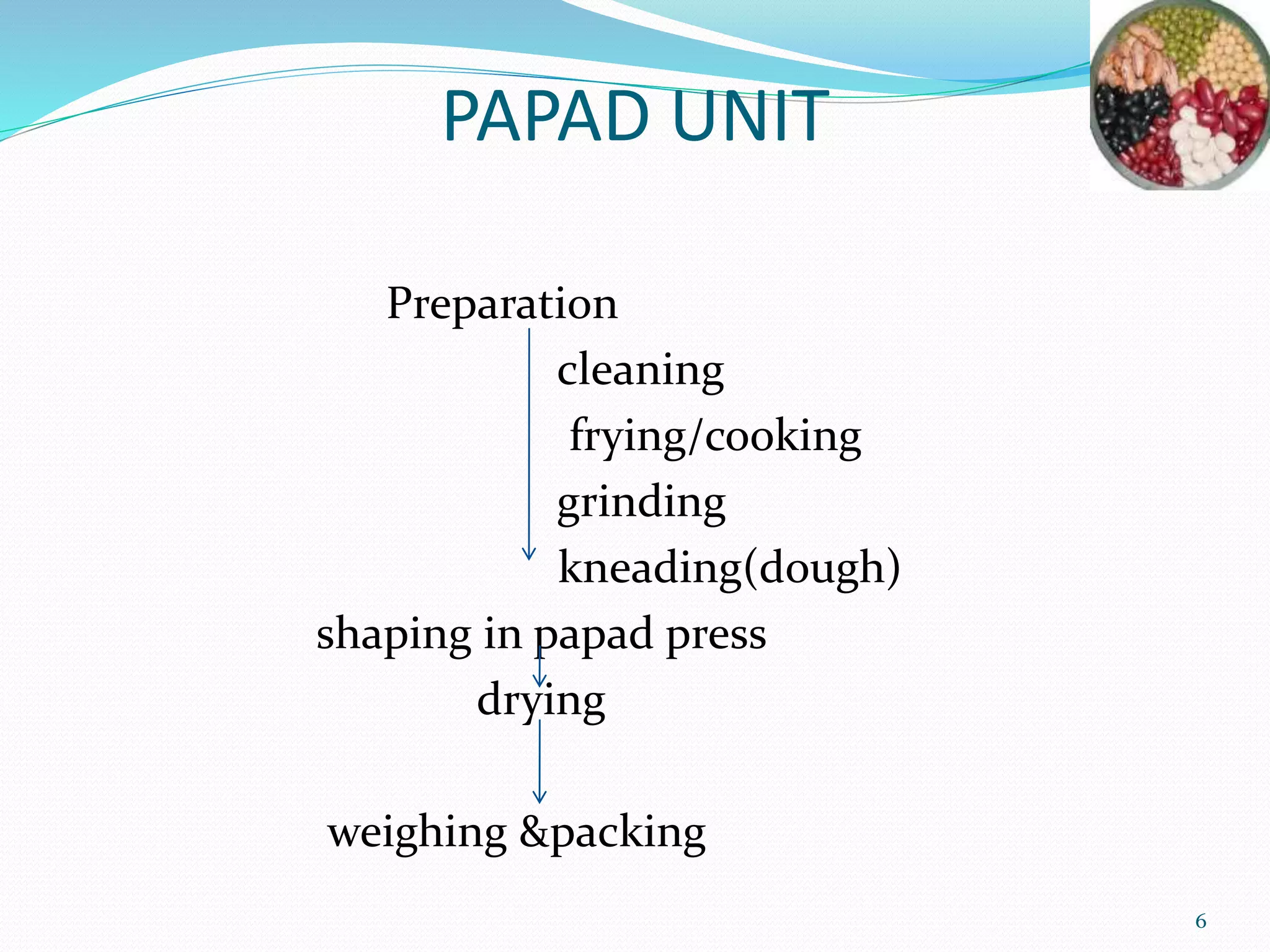

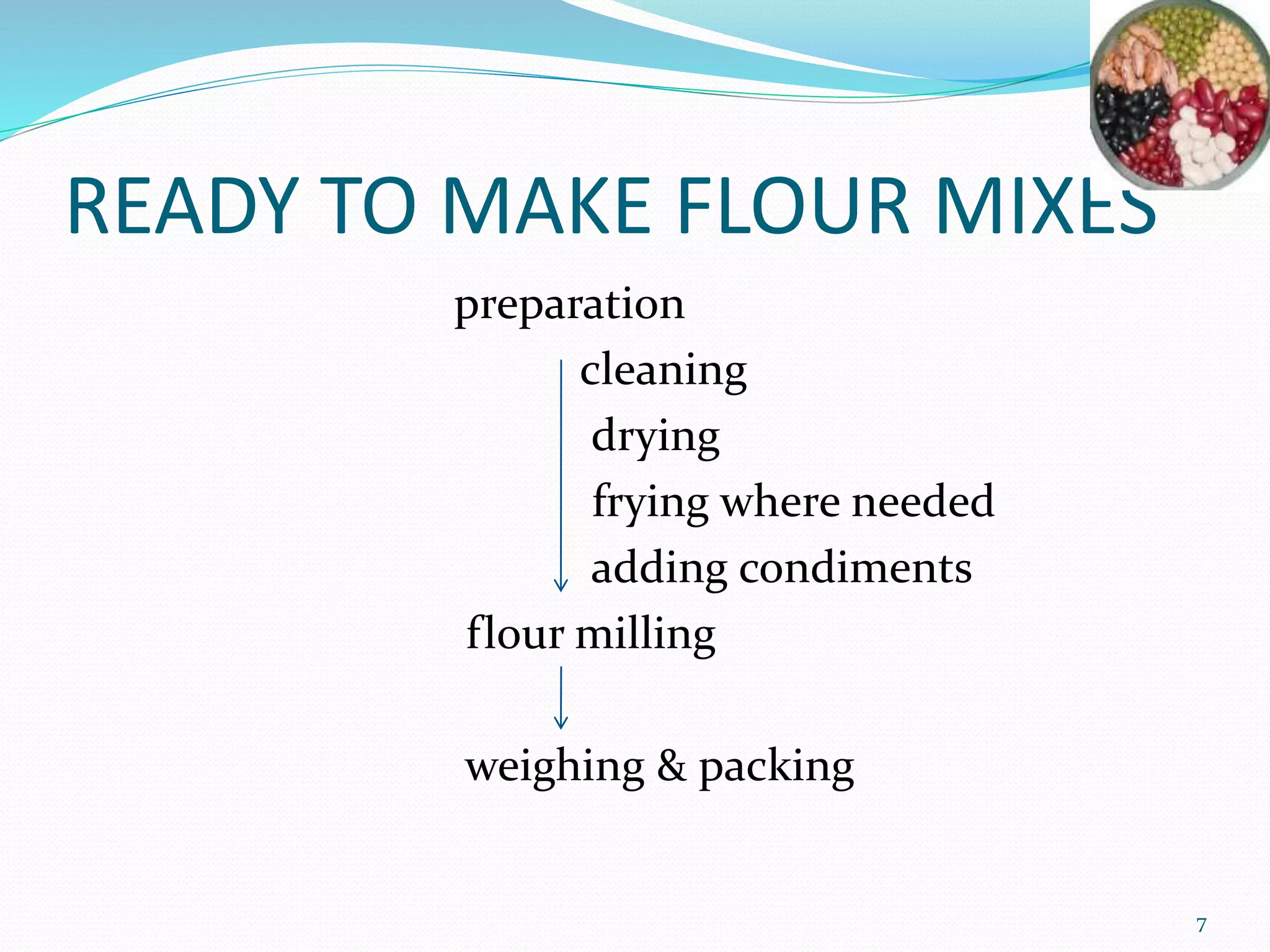

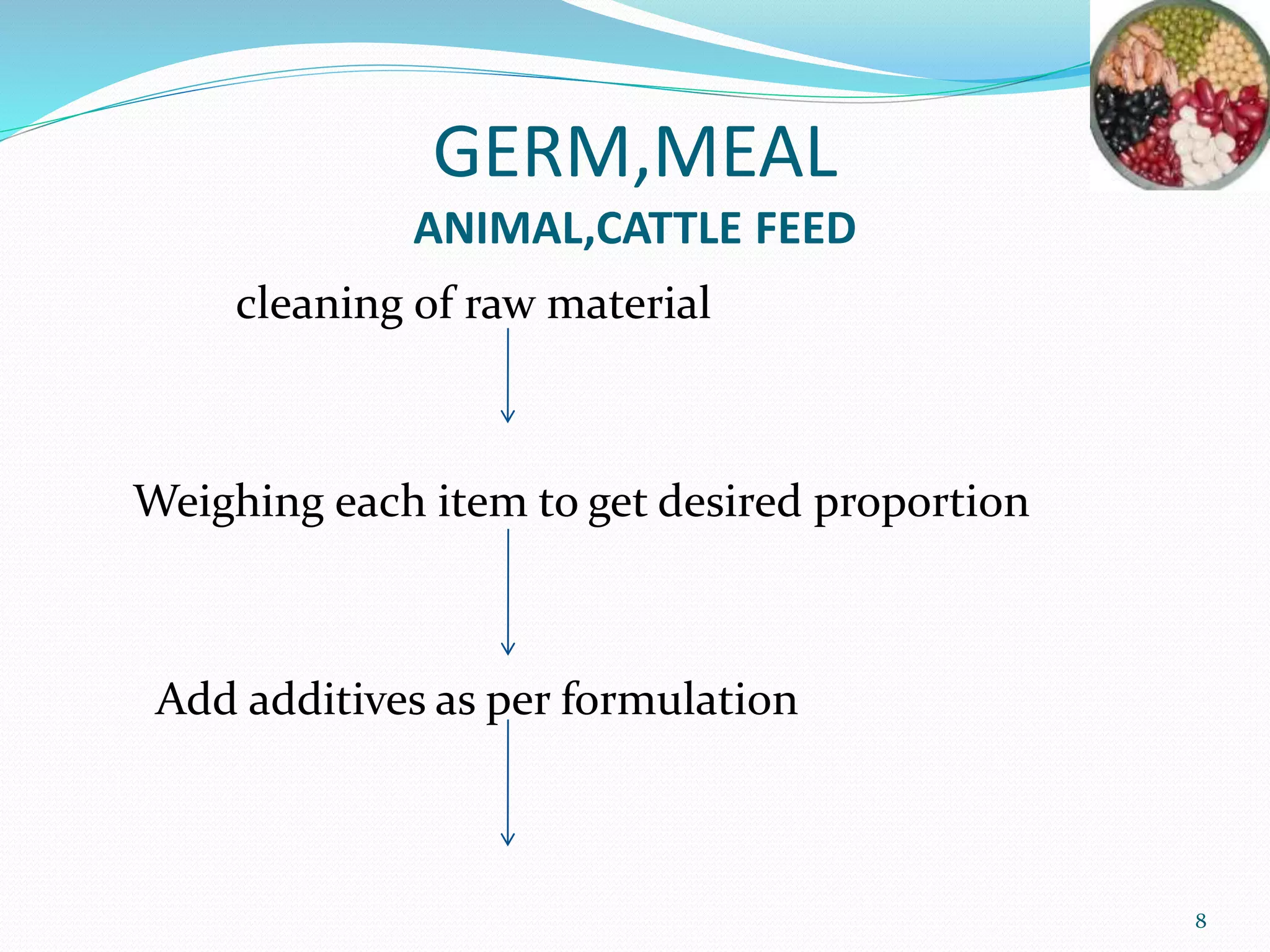

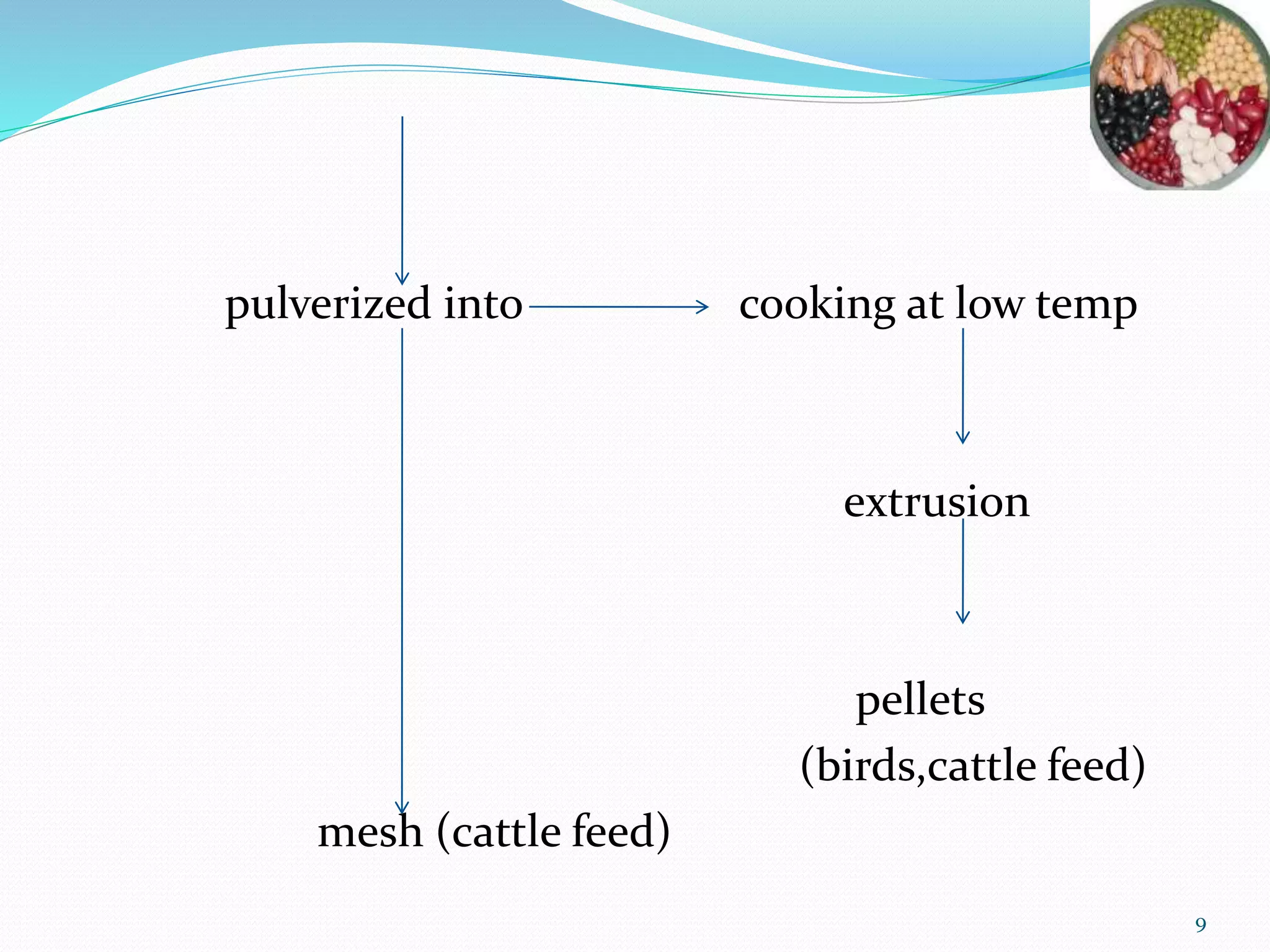

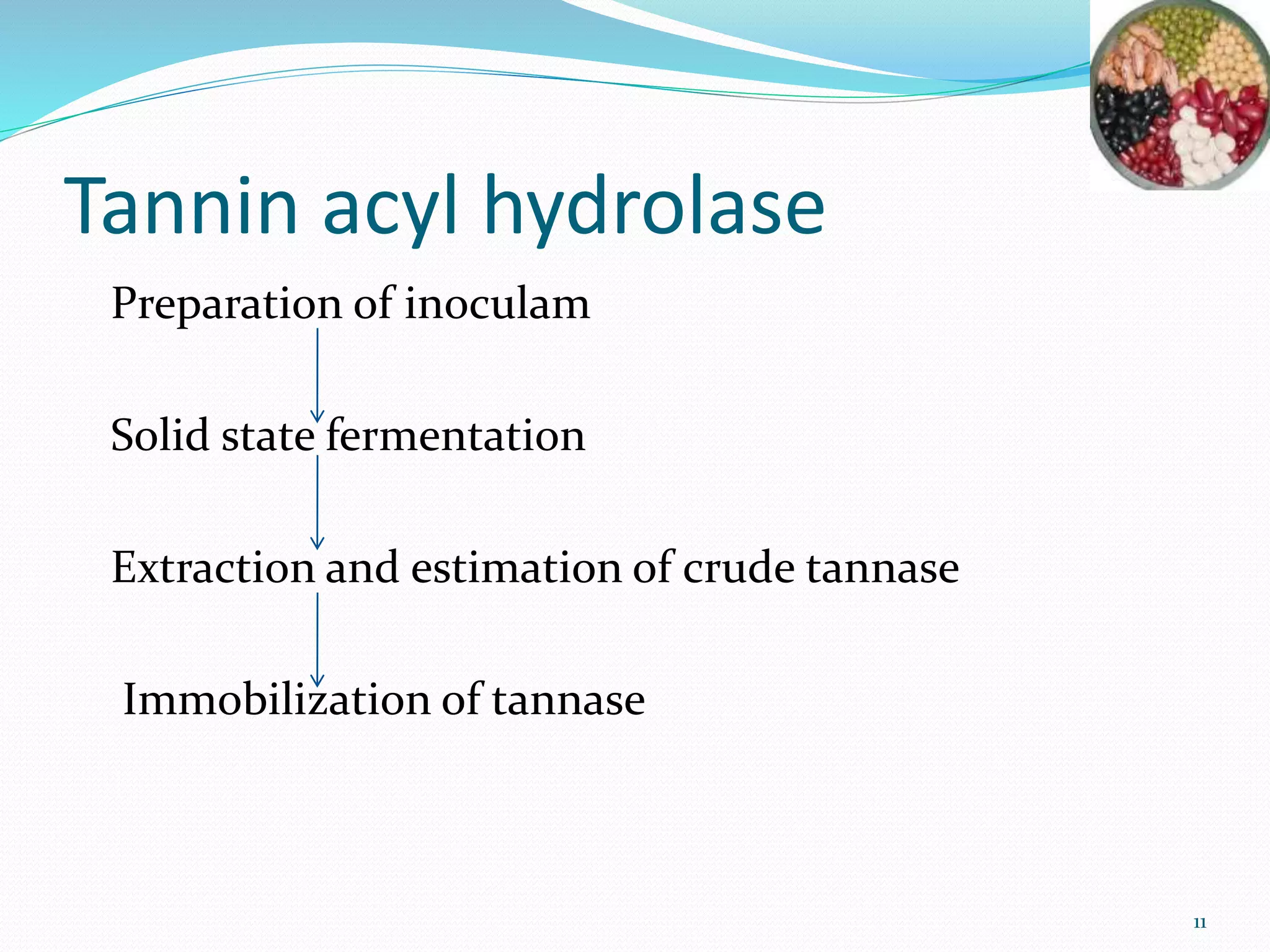

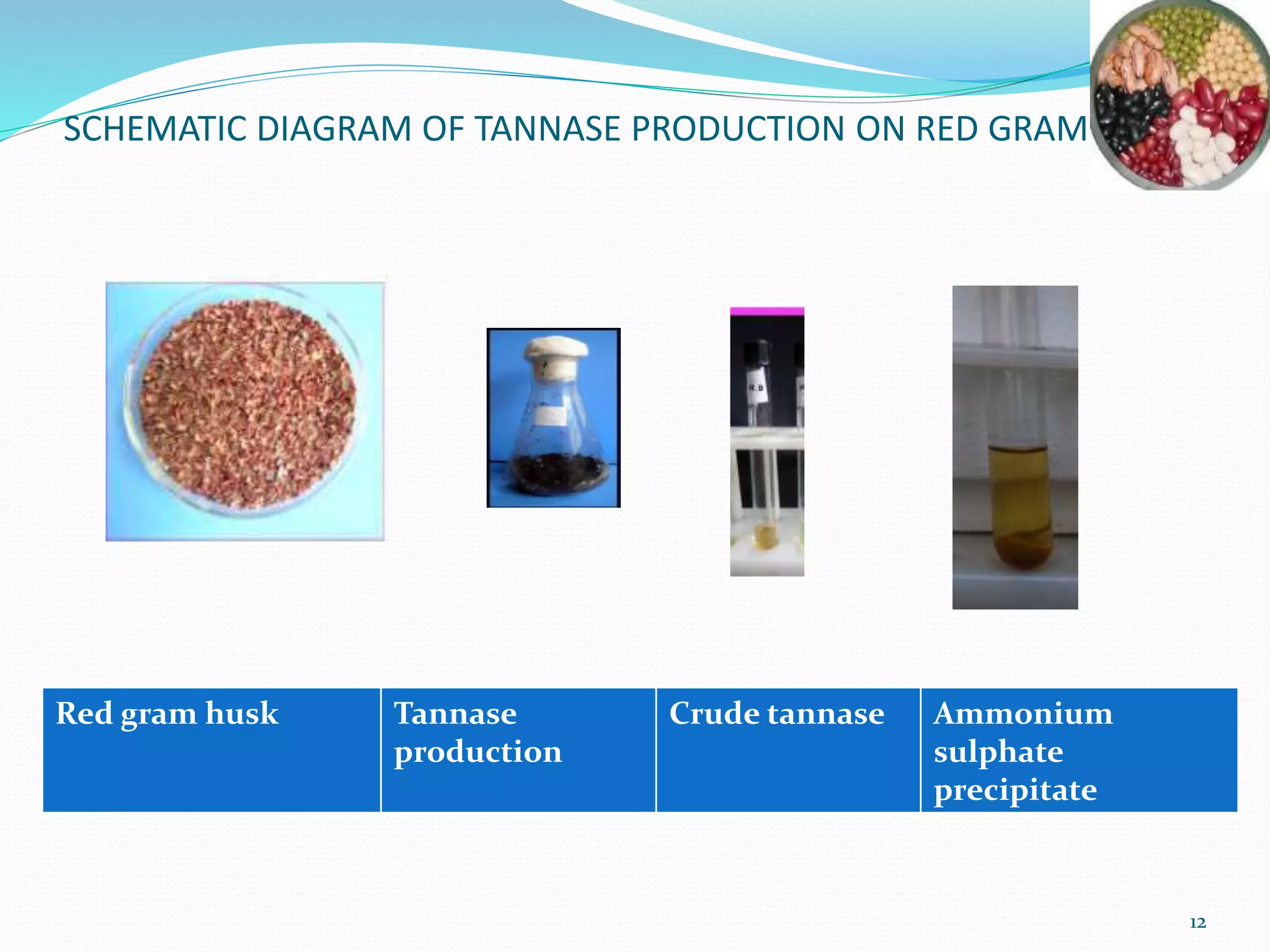

Pulses are rich in proteins and are mainly consumed after milling, which removes the outer husk and splits the grain. Byproducts of milling include husk, peel, germ, and brokens. Dry milling produces brokens that can be used to make ready-to-fry snacks by cleaning, powdering, sieving, seasoning, kneading, cooking, and extruding. The husk can be used for solid state fermentation to produce tannin acyl hydrolase using red gram husk through inoculation, fermentation, extraction, immobilization, and purification by chromatography. Other byproducts include papad mixes, flour mixes, and animal/cattle feed produced through various preparation