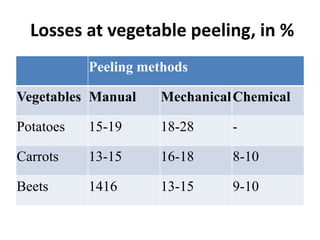

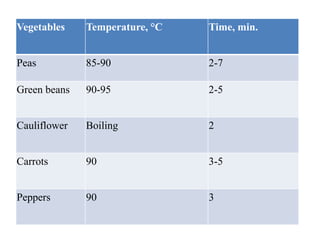

This document discusses the preliminary processing operations performed on fruits and vegetables after harvesting. It describes sorting, grading, washing, peeling, sizing, and blanching. Sorting separates produce based on physical properties like size and shape. Grading classifies by quality standards. Washing removes surface contaminants with water. Peeling removes inedible skins using methods like mechanical, heat, lye, or flame peeling. Sizing reduces produce to favorable sizes. Blanching heats produce briefly to inactivate enzymes and microbes, retain color and nutrients, and ease freezing/canning. It lists temperatures and times for common vegetables.