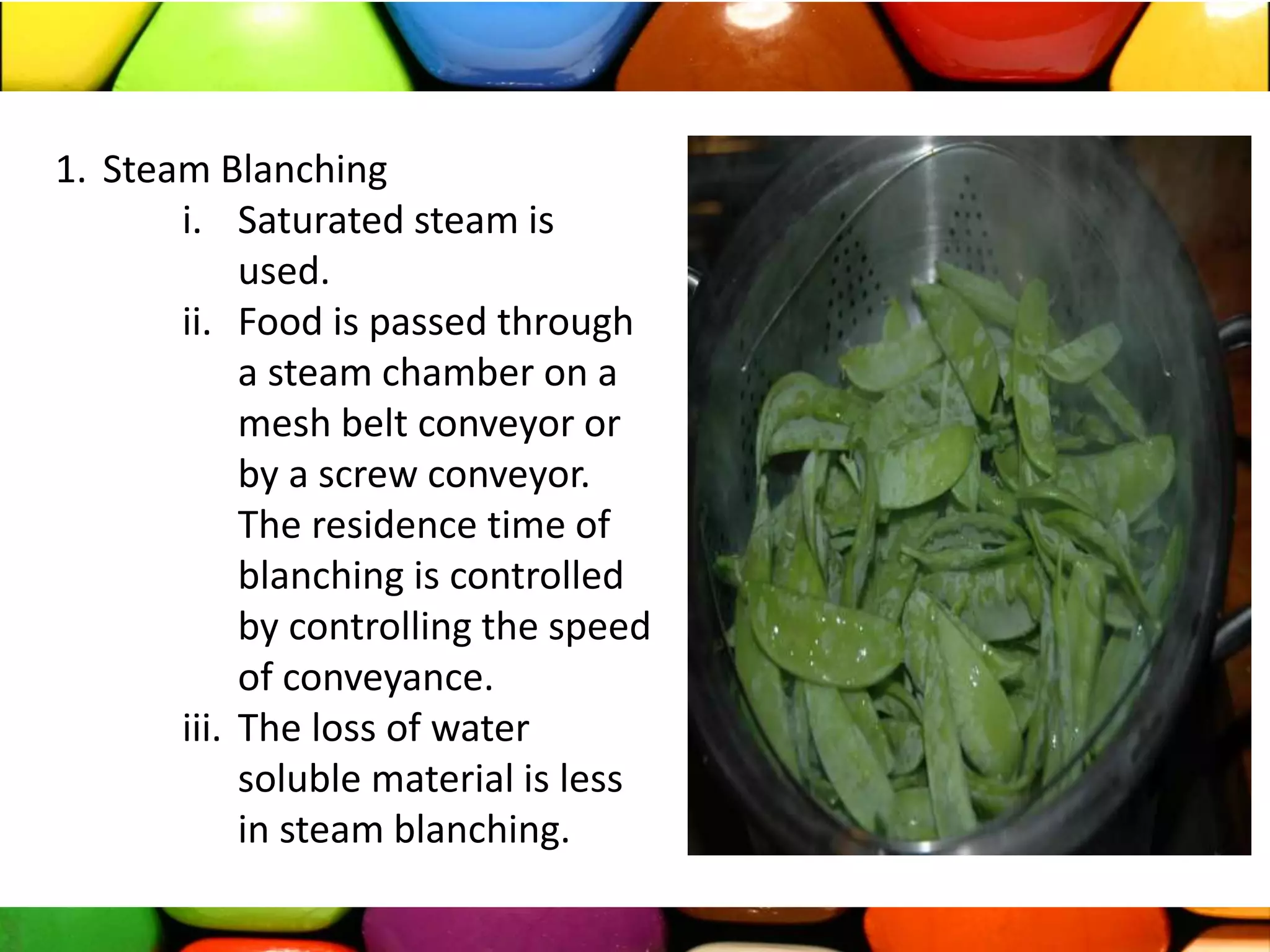

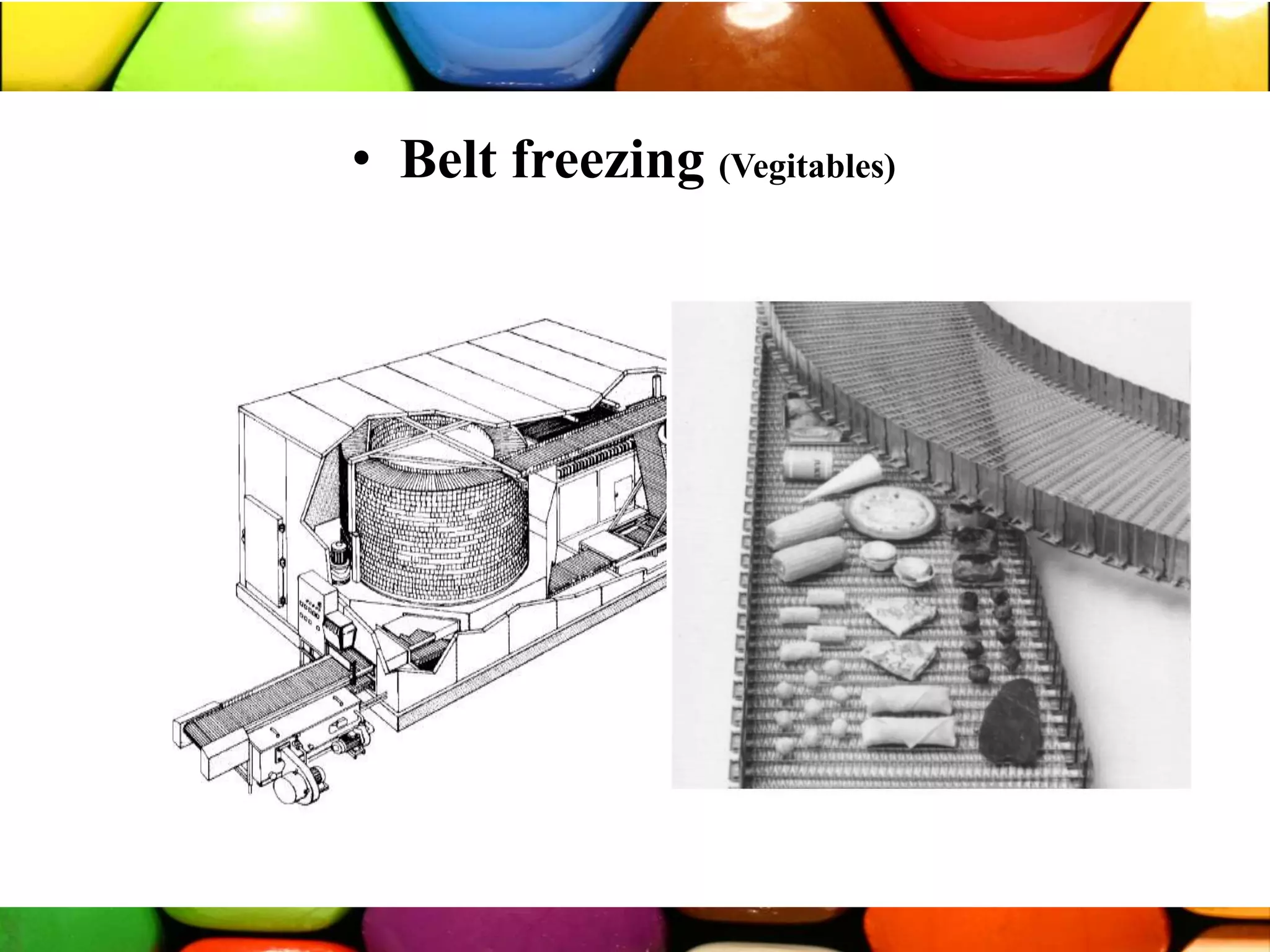

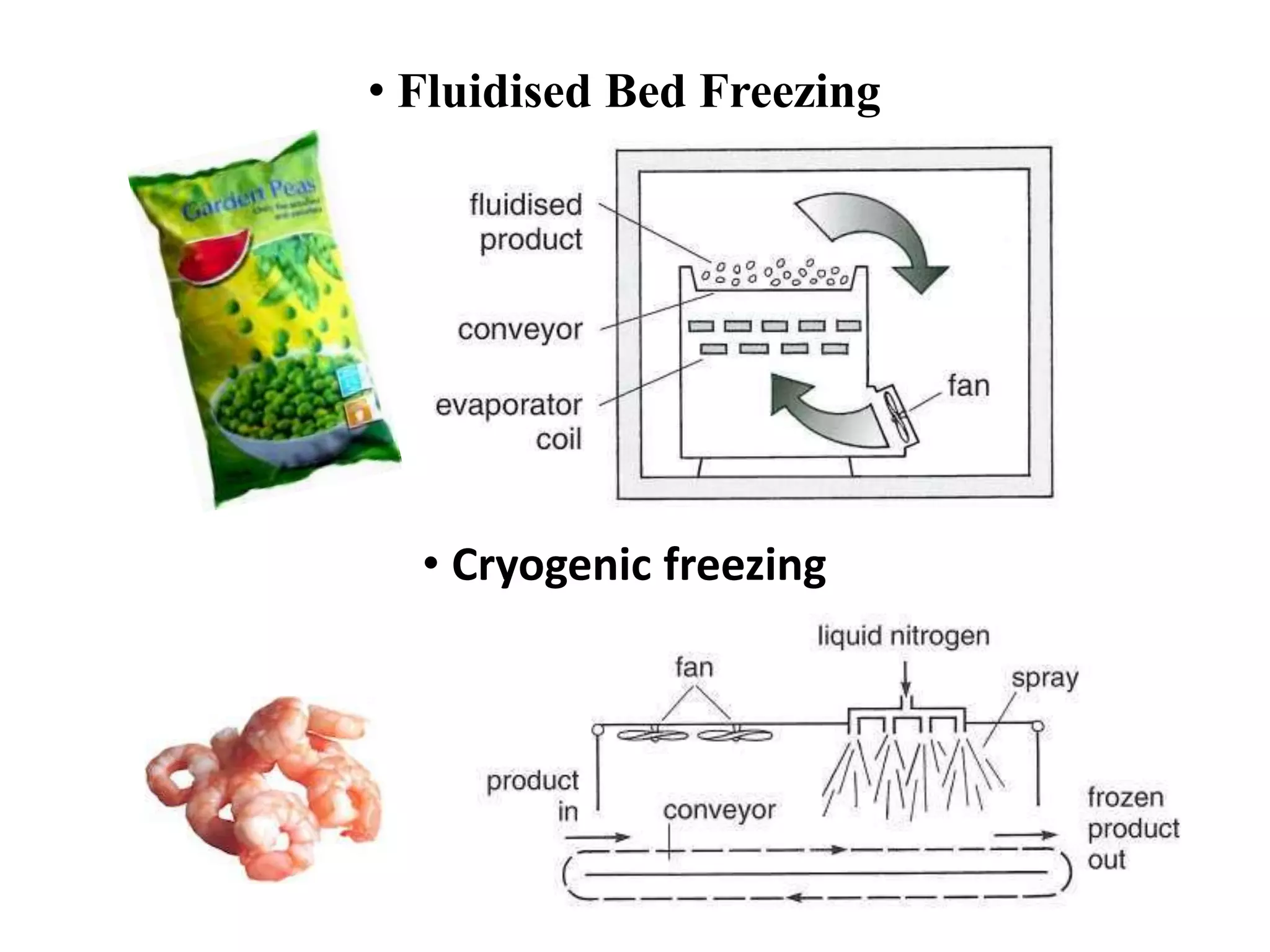

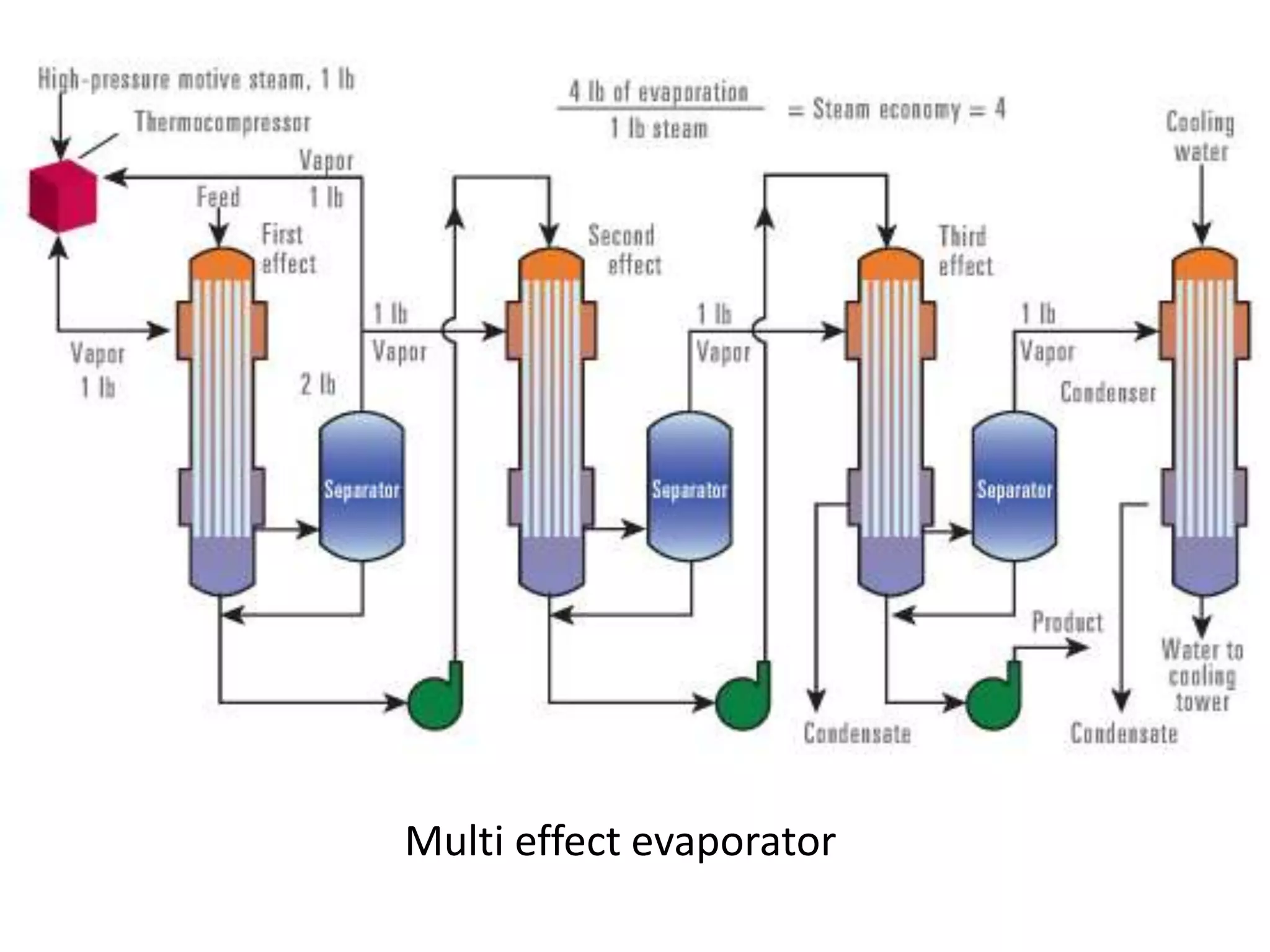

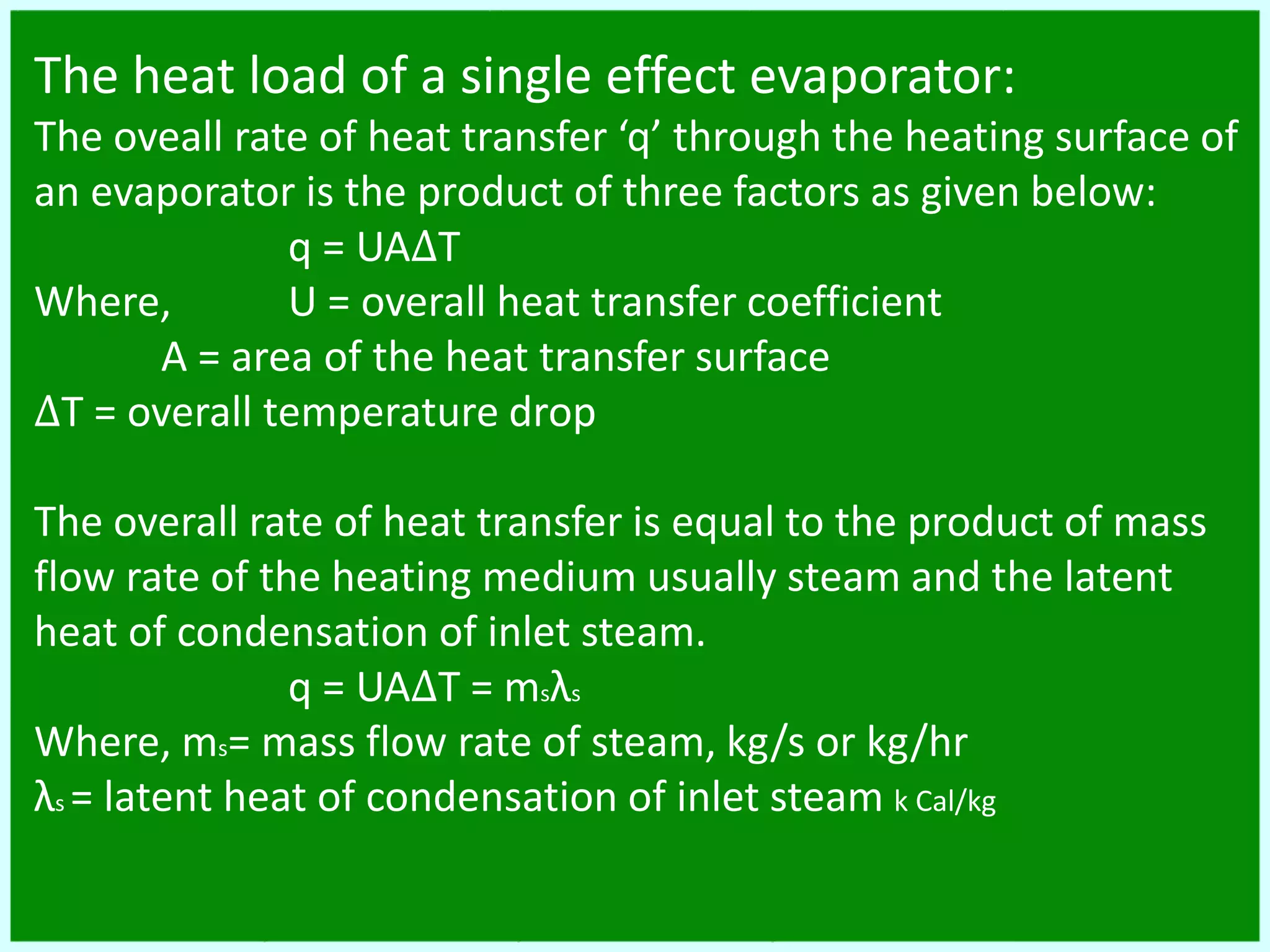

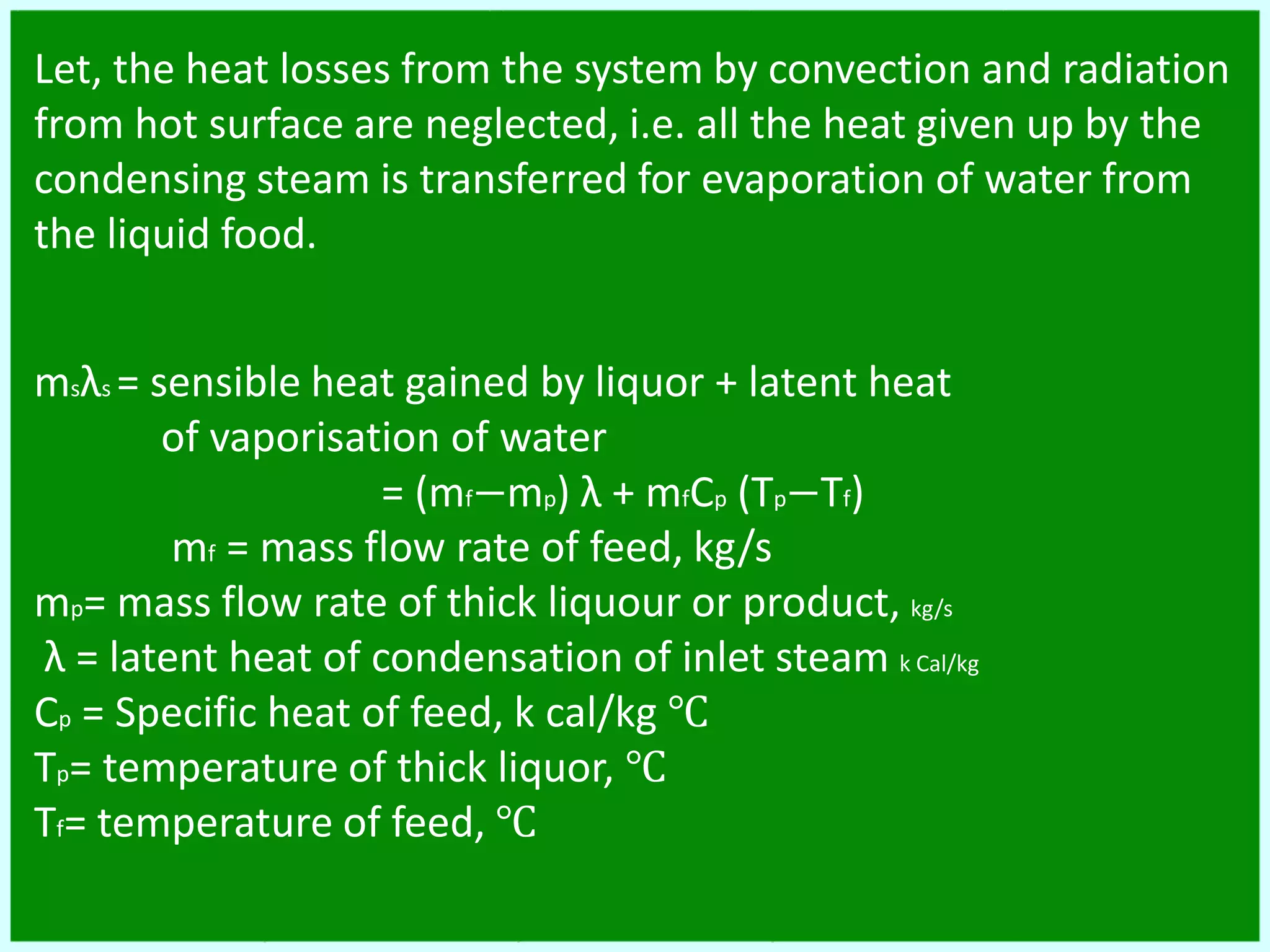

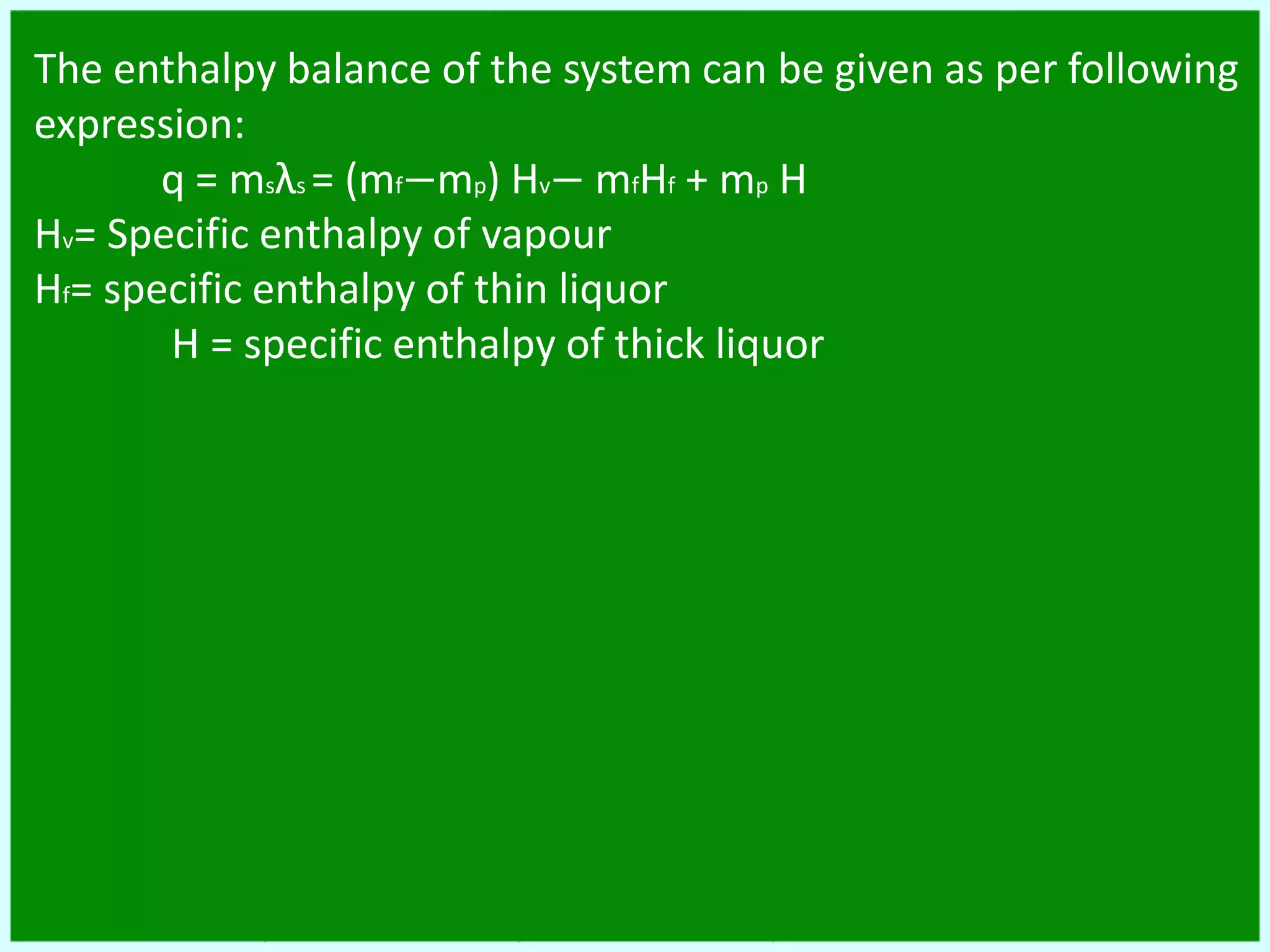

The document discusses fundamental operations in elementary food engineering, including thermal treatments such as pasteurization, sterilization, blanching, dehydration, freezing, and evaporation. It highlights the importance of these processes in preserving food quality, controlling spoilage, and improving texture and taste, detailing methods and equipment used in each operation. The document emphasizes the scientific principles underlying food engineering operations and their impact on food safety and stability.