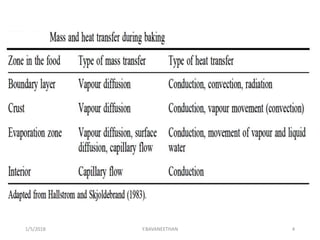

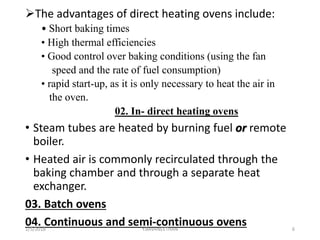

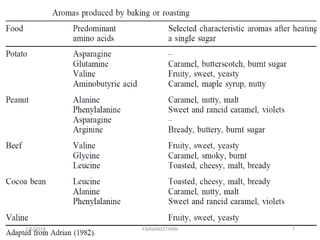

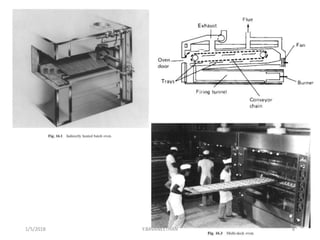

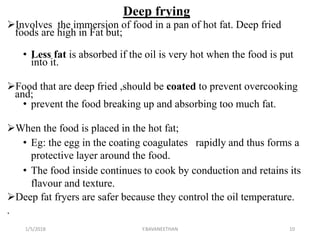

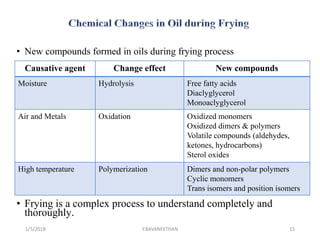

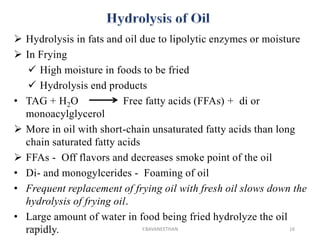

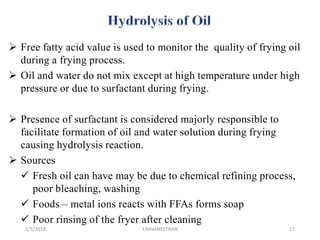

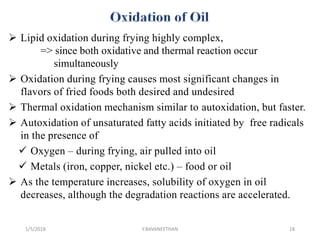

Baking and roasting are similar processes that use heated air to alter the quality of foods. Baking is typically used for flour-based foods and fruits, while roasting is for meats, nuts and vegetables. Both processes involve heat transfer through radiation, convection and conduction to cook foods internally without exceeding 100°C. This causes surface changes that improve qualities like moisture retention. Ovens can be direct or indirect heating types, and batch, continuous or semi-continuous systems. Frying methods include deep frying by full submersion in hot oil, shallow frying with partial submersion, and stir frying using minimal oil. Frying oils undergo hydrolysis and oxidation over time, producing compounds that degrade quality